Solar by Summer, Wood by Winter: Ways to combine solar collectors and wood gasification boilers

© Copyright 2014, J. Siegenthaler, all rights reserved

As anyone with a solar thermal system in a challenging winter climate knows – you need a backup heat source during much of the winter doldrums. In most systems the supplemental heating comes from conventional fuels such as electricity, gas, or fuel oil. But there’s another possibility that allows “stored solar energy” to provide the supplemental heat “real time” solar energy cannot provide. That source is wood: a fuel created from atmospheric carbon dioxide by the solar driven process called photosynthesis.

Stored Sunshine: In my area, firewood is plentiful and relatively inexpensive. You can buy all you want for about $70 / face cord, delivered. At a nominal 75% conversion efficiency in a wood gasification boiler, that works out to about $12 per million Btus delivered. In rural areas of the Northeast, the primary heating fuel is #2 fuel oil and propane. The current price for #2 oil is about $3.80 per gallon. At 85% conversion efficiency that works out to $31.92 per million Btus delivered. That’s almost 3 times the cost of heat provided by a wood gasification boiler.

The plentiful supply and relatively low cost of firewood in the Northeast, in combination with high cost of conventional fuels, has created strong interest in using wood for central heating. State-of-the-art wood-gasification boilers are a great way to efficiently convert fire wood into heated water. After that, modern hydronics technology offers many ways to store and distribute that energy for both space heating and domestic hot water.

Still, most of the people I know don’t want to maintain operation of a wood gasification boiler in summer, when the typical load is domestic water heating.

So if solar heat generation is ideal for the summer, while wood based heating makes sense for colder and cloudier weather, why not link these two systems to a common storage and distribution system? Hydronics technology makes this possible.

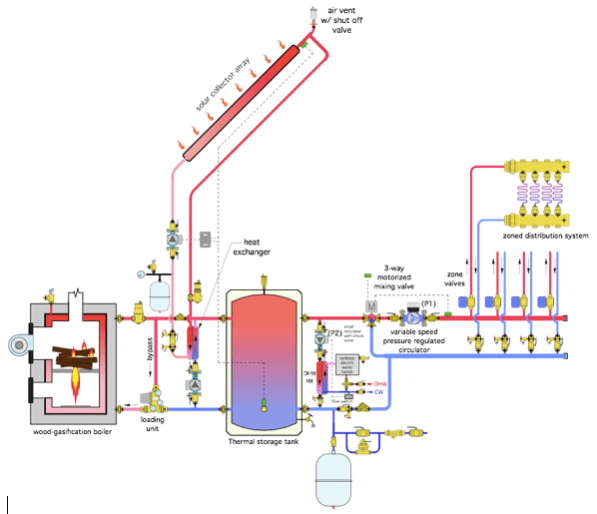

Two into One: Figure 1 shows one way to combine a wood gasification boiler and solar thermal array into a common system.

The two heat sources are linked at the storage tank. Either one can operate independently of the other. It’s likely that the boiler will not be stoked up if the owner is expecting a period of significant solar gain. However, if the boiler is operating, and the sun comes out, the collector array can still operate, provided the collector temperature rises several degrees above the storage tank temperature.

The solar subsystem is a closed loop filled with an antifreeze solution. Heat is transferred to the system water using a generously sized brazed plate heat exchanger. The circulator between the storage tank and lower temperature size of the heat exchanger includes a check valve. This prevents heat migration into the solar subsystem when it is not operating. The collector array circulator also includes a check valve to further guard against heat migration.

A thermostatically controlled “loading unit” is installed near the inlet to the wood gasification boiler. This device consists of a circulator, thermostatic mixing valve, and flapper-type check valve. Its purpose is to prevent internal flue gas condensation (which creates creosote) within the combustion chamber. When the circulator in the loading unit is operating, the pressure differential it creates forces the flapper-type check valve to remain closed. The internal thermostatic element regulates the proportions of how water from the boiler outlet and cooler water from the storage tank that are blended to keep the boiler inlet temperature suitably high (typically above 130 ºF for 20% moisture content firewood).

During a power failure, the flapper type check mechanism in the loading unit allows natural convection flow between the boiler and thermal storage tank. In consideration of this, the path between the boiler and storage tank should have low flow resistance. The check valve seen on the supply pipe from the boiler to the storage tank must be a flapper type check valve. Never use a weighted plug flow check or spring loaded check valve in this location. They create too much resistance to buoyancy driven flow.

The space heat distribution system could use one or more types of low temperature heat emitters. Good choices include radiant floor, wall, or ceiling panels, or panel radiators. I suggest that all heat emitters be selected so that the system can deliver full design load output without exceeding a supply water temperature of 120 ºF. Even lower supply water temperatures are better if possible with large surface area radiant panels. The lower the supply water temperature, the lower the temperature at which the storage tank can supply heat. This will increase the efficiency of the solar collectors, and also lengthen the time between boiler firings

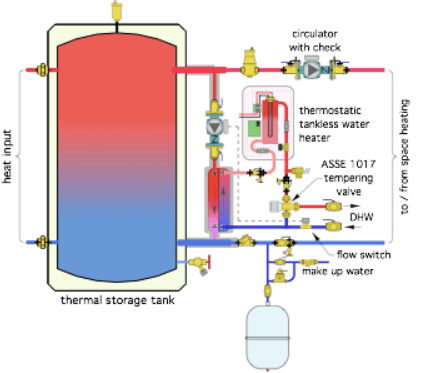

Sidearm Domestic: Domestic water is preheated by an external stainless steel heat exchanger as shown in figure 2.

The domestic water flow switch closes whenever it detects a demand of 0.6 gpm or more. This turns on a small circulator, which moves system water from the storage tank through the primary side of the heat exchanger. Domestic cold water passes through the other side of the heat exchanger. Its temperature rise depends on the water temperature within the storage tank. If the tank is 130 ºF or higher, and the target domestic water delivery temperature is 120 ºF or lower, a suitably sized heat exchanger could provide the full temperature rise. If the storage tank is cooler, the heat exchanger provides preheating. A thermostatically controlled electric tankless water heater adjusts the input wattage to its element to “top off” the temperature rise as required.

It may also be possible to “piggy back” a signal from the element contactor in the tankless electric water heater to determine when the domestic water flow rate reaches the turn-on threshold of the heater. This would eliminate the need for the external flow switch described above. The “piggy back” signal would likely be at 240 VAC. This could be used to operate a relay if a standard 120 VAC circulator is used between the storage tank and heat exchanger. Be sure to check with the manufacturer of the tankless unit to verify if this is possible and within the warranty constraints of the unit.

Also keep in mind than tankless electric water heaters have a high limit safety device that opens the element circuit if the incoming water temperature exceeds a set upper limit (i.e.130 ºF). Some units require a manual reset when this happens. Others will automatically reset, but only when the incoming water temperature drops to around 70 ºF. Some units can be ordered with an optional 180ºF upper limit. These would be appropriate in systems where the thermal storage tank, under the right conditions, could cause the water leaving the heat exchanger to be above the 130 ºF setting.

When this type of system leverages the strengths of both solar and wood-fired boilers, and even a small amount of electric resistance heating, to provide space heating and domestic hot water. It’s a good combination for clients who are committed to “green energy,” want to use state-of-the-art hardware, and expect the unrivaled comfort delivered by a well-designed hydronic system.

Want to Know More? I’m very excited about the potential for high efficiency biomass heating sources supported by modern hydronics technology. When properly executed this combination allows use of renewable resources at high efficiency, while delivering unsurpassed comfort, versatility, and low operating cost.

Beginning September 15th, I’ll be partnering with HeatSpring Learning Institute and the Biomass Thermal Energy Council (BTEC), to teach a 20 instructional hour, AIA-accredited online course entitled: Hydronic-Based Biomass Heating Systems.

This course will dig into the details of high efficiency boilers using cordwood, wood chips and pellets. It will discuss the latest methods for combining these boilers with the best in modern hydronic heating. The course is capped at 50 students with 30 discounts.

If you are interested in modern wood based biomass-heating systems take a look at the full course outline. You can also test-drive the course for free!

John Siegenthaler, P.E., is a mechanical engineer and graduate of Rensselaer Polytechnic Institute, a licensed professional engineer, and Professor Emeritus of Engineering Technology at Mohawk Valley Community College. “Siggy” has over 32 years of experience in designing modern hydronic heating systems. Learn advanced techniques and strategies for designing and installing biomass heating systems with John during his 10-week online course, Hydronic-Based Biomass Heating Systems (starting September 15th). *This course is quickly filling and will be capped at 50 student with a limit of 30 discounts.

Join the conversation: