If you’re a plumbing and heating contractor who has been told by your distributor that all PEX F1960 expansion fittings are the same, be forewarned. That is simply not true. And the differences in low-quality F1960 fittings can come with considerable risk to your installations and your reputation.

Pioneered by Uponor in 2000 through the design and development of their proprietary ProPEX® connection system, ASTM F1960, Standard Specification for Cold Expansion Fittings with PEX Reinforcing Rings for Use with Cross-linked Polyethylene (PEX), was the result of a collaboration between Uponor and the American Society for Testing and Materials (ASTM) international standards organization to provide a better solution for connecting PEX in plumbing, fire safety, radiant heating and cooling, and mechanical piping systems.

With the popularity of PEX continuing to grow in residential and commercial construction, a recent influx of engineered polymer (EP) F1960 expansion fittings have flooded the market claiming to be “just the same as ProPEX”. However, the industry needs to be aware that some manufacturers and suppliers are offering a lower-quality product that can put a system at significant risk for leaks or poor performance.

Understanding Certification vs. Compliance

ProPEX® fittings are certified by a third-party agency, NSF International, to prove the product is designed and manufactured to the ASTM F1960 standard. In addition, ProPEX fittings also include additional internal quality testing that extends beyond ASTM F1960 standard requirements to provide a higher-quality product.

Some suppliers claim their fittings are compliant to F1960, which means, in their opinion, they meet the standard. However, there is no third-party agency to confirm that compliance. This confusion between certification and compliance is resulting in PEX piping installations with lower-quality connections that are putting systems at risk for failure and jeopardizing installers’ reputations.

So, what happens when a third-party agency isn’t involved to keep manufacturers and suppliers in check? A random sampling of these lower-quality F1960 EP fittings revealed a reduced internal diameter (up to 50% in some instances), which restricts flow and limits system performance. Additionally, Uponor has begun to receive claims for failed connections that, after investigation, were found to be different suppliers’ low-quality F1960 fittings.

Contractors need to be vigilant when ordering and purchasing PEX expansion fittings to ensure they are actually getting ProPEX to help keep their installations strong and their reputations solid.

Here are some important physical attributes to look for when purchasing ProPEX fittings at your local distributor.

Manufacturer Name and Material Designation

The most obvious way to ensure you have a ProPEX fitting is by checking for the Uponor logo. Some older ProPEX fittings may have a “W” on the fitting instead, which stands for Warnock Hersey (another third-party certification) or Wirsbo. Anyone who has been in the industry for a couple of decades will recognize Wirsbo as the original company name of Uponor from 1984 to 2006.

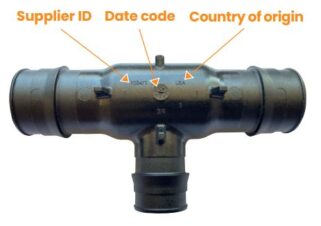

Quality Control Markings

ProPEX fittings are a highly engineered product, and Uponor manages the manufacturing source for every part to ensure product is produced to consistent manufacturing standards. In fact, the companies that mold ProPEX EP fittings are partners that are integrated into the codes.

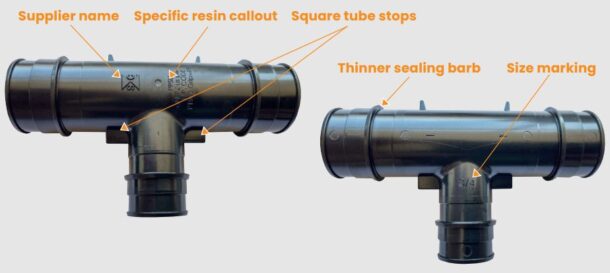

Thicker Tube Stops and Wider Sealing Barb

After more than 30 years of testing and refining the fitting design, ProPEX products feature thicker tube stops on the face of the fitting along with wider sealing barbs that create a stronger connection.

Other F1960 Fittings

Easy identification of other F1960 fittings include a different supplier logo and specific resin callout as well as thin, square tube stops near the base of the fitting, a thinner sealing barb, and only the size marking on the back. The thin tube stops are especially problematic as the expanded PEX pipe can extend past the stops and cause leaks.

The Right Tools

While some may feel using any expansion tool will do the job, the tool you use actually does make a difference in the quality of the connection. Milwaukee® ProPEX® M12™ and M18™ expansion tools have been designed to Uponor’s specification and performance requirements with Uponor PEX-a pipe and ProPEX expansion rings as a system. Making a connection with Uponor PEX-a pipe, ProPEX rings, and ProPEX fittings using a different tool can, in fact, compromise the quality of the connection.

A Complete System and Solid Warranty

Lastly, ProPEX connections are part of a complete system that includes pipe, rings, and fittings. In fact, The Canadian Standards Association (CSA) tested and listed the system, which includes Uponor PEX-a pipe, Uponor ProPEX rings, and Uponor ProPEX fittings, and Uponor is the only brand to have this CSA system certification.

Installing a complete system comes with valuable benefits, such as a 25-year transferable limited warranty for added confidence in a solution that is designed and manufactured to last. Many generic F1960 fittings have limited warranties — some are as little as one year. And, if the fitting is used with a different manufacturer’s PEX pipe or expansion rings, there could be a question around who is liable for the claim. You don’t want to be caught in the middle of that dilemma!

Simply put, keep your installations solid and your reputation strong by ensuring you’re getting the right parts from your distributors and installing a complete system covered by one warranty holder. Don’t take the risk with low-quality products that won’t cover you when you need it.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Kim Bliss is the technical and marketing content manager at Uponor. She can be reached at kim.bliss@uponor.com.

Join the conversation: