Mechanical Hub recently interviewed David Fink, President and Executive Director of The Plastics Pipe Institute, Inc. (PPI). Mr. Fink, a veteran of the plastics pipe industry, previously served as the Chairman of the PPI Board of Directors from 2017 to 2019, and has held a number of other leadership positions within the organization. PPI is the major North American trade association representing all segments of the plastic pipe industry.

Mechanical Hub recently interviewed David Fink, President and Executive Director of The Plastics Pipe Institute, Inc. (PPI). Mr. Fink, a veteran of the plastics pipe industry, previously served as the Chairman of the PPI Board of Directors from 2017 to 2019, and has held a number of other leadership positions within the organization. PPI is the major North American trade association representing all segments of the plastic pipe industry.

Fink most recently served as the Senior Vice President at PPI member company, WL Plastics, and previously at Dow Chemical in the company’s polyolefin resin business with the majority of the years being part of growing its plastics pipe resin business. While at WL Plastics, he oversaw significant growth of the company’s sales in the polyethylene pipe market segments including gas gathering and distribution, municipal water distribution, industrial and mining applications, telecommunication conduit, and geothermal.

MH: You’ve been on the job for a little more than a month, what’s a typical day at PPI?

DF: Working with our talented PPI engineers, staff, and membership to meet the needs of the plastics piping industry. This includes helping design engineers and pipe users to understand correct applications of the products we represent; overseeing the development and revision of industry regulations, codes & standards; and advancing the industry’s knowledge of Plastic Piping Materials through various education and advocacy activities.

MH: What is the mission and vision of PPI?

DF: The Mission of the Plastics Pipe Institute is to advance the acceptance and use of plastic pipe systems through research, education, technical expertise and advocacy. There are 4 pillars within our strategic plan:

- Research & Education (develop technical information about the products and connecting target audiences with content)

- Advocacy/Voice (Serve as the voice of the industry for plastic pipe systems)

- Expansion and Growth (Support market share growth for plastic pipe systems, and broaden the sphere of influence for the industry)

- Member Engagement (increase the value of membership through active involvement in PPI)

MH: The market has seen significant growth over the past 10+ years, how is the current economic climate affecting the industry? What are some of the challenges and how is PPI addressing those challenges?

DF: The recent strong construction economy has provided the plastics pipe industry lots of opportunity for growth and expansion, including both new construction and rehabilitation of existing infrastructure. Plastic piping is finding its way into new applications every day, as engineers and end users better understand the capabilities of these proven systems. This stems from the continued success of plastic pipes to outpace the growth of alternate materials due to extended service life, corrosion resistance, ease of installation, and lower total installed costs and maintenance over the lifetime of the system.

MH: How is PPI addressing environmental issues in the industry and the “Green” movement?

DF: Plastics piping systems do not corrode or leak over time, and thus save valuable resources like our water supply. Their longer life expectancy saves on replacement materials and costs. They are lightweight, so more material can be shipped on a truck, reducing carbon emissions related to transportation. And many plastics can be recycled at the end of their lifetime. Some plastic pipe materials, such as drainage pipe, already utilize post-consumer recycled plastic material content.

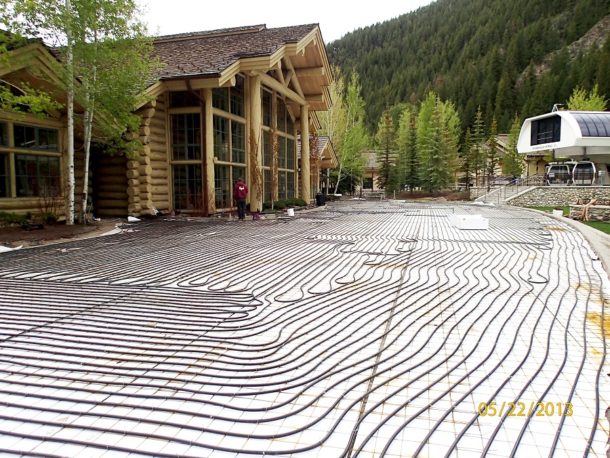

Renewable energy sources, solar and wind for example, utilize plastic conduit to protect the power cables. In the plumbing and mechanical industry, plastic pipes are an essential part of geothermal ground loops, ; radiant heating and cooling systems,, snow melt systems; and fire protection systems. In agriculture, plastic pipes provide irrigation and drainage for fields to increase crop production.

MH: What are a few trends that PPI has identified in the industry?

DF: With greater acceptance of plastic materials, especially for commercial plumbing and mechanical applications, comes the growing demand for education and training, so we are innovating to try and meet those needs. With economic growth challenging the N.A. workforce, including contractors and engineers, there is also higher demand on non-biased industry experts, such as PPI staff, for design and application guidance when using these materials.

MH: How do you see PPI changing in the future, and how do you see yourself helping in creating that change?

DF: I look forward to leading the organization as PPI will continue as the voice of the plastics piping industry. As new plastic materials are created or as current materials evolve, PPI will work with the industry to provide the technical support for the standards and codes arena and educate and train the next generation of engineers, contractors, and other key stakeholders on the value that plastics piping systems bring to the industry. PPI has been growing constantly since the year 2000, in terms of members, staff, and the scope of our work. We don’t see this trend slowing down any time soon.

MH: How are standards used in the industry, and what have they meant to its overall history and development?

DF: Standards improve product quality, provide engineers and end users with confidence that these are products that they can count on to meet their needs, and strengthen the market by providing consistency, safety, and reliability. Believe it or not, several plastic pipe standards were first developed in the 1970s. In fact, the first ASTM standard for PEX was published in 1984. These standards are constantly evolving, and PPI’s engineers focus a lot of their time on standards development. It’s an essential part of the safety and reliability that our systems deliver every day.

MH: How are you strengthening and building on your brand, training and resources available to members and non-members?

DF: Continuing to develop technical content including design manuals; installation guidelines; engineering calculators, case studies, and other related materials, and sharing these tools through our website. PPI engineers are present in various organizations, such as ASHRAE, ASPE, RPA and HIA-C, to act as the Subject Matter Experts on plastic piping materials and systems. PPI remains active in standards and codes organizations to create and improve their publications by continuing to raise the bar on reliability and performance of plastics piping systems. Finally, PPI is out in the field with our members, training and educating and will be developing more online educational content to provide this training to a broader audience.

MH: What are some of the things you’re doing to boost PPI’s visibility?

DF: I’ll be active with other organizations with similar interests in advocacy efforts to raise awareness on the features and benefits of plastics piping systems. PPI is also increasing our social media and website presence to reach a larger audience and has begun development of online education platform using a learning management system.

MH: In closing, is there anything you’d like to add?

DF: It’s an exciting time for plastics in piping applications as more and more people are learning about the features and benefits that plastics bring to the built environment over older, traditional materials. Plus, improvements in current materials and innovations in new materials are opening new applications for plastic materials. I’m looking forward to working with PPI staff and its membership and partner organizations to continue to grow the marketplace for plastics piping solutions.

Join the conversation: