In 1862, while prospecting for what was thought to be a vast deposit of silver and gold, John Searles made a serendipitous discovery in this unforgiving and isolated area located southwest of Death Valley. Borax and other minerals so plentiful, that the engineer complained they would interfere with refining the long sought, but never unearthed, metal ore.

Within a decade, a borax mining business was formed at what is now known as Searles Dry Lake, a depository rich with useful chemicals and minerals that serve a wide variety of industrial and agricultural needs. Brine from these salt layers is today’s source of sodium, potassium, borate, carbonate and sulfate, which are processed in facilities that trace their lineage back to John Searles’ San Bernardino Borax Mining Company.

From a modest production of a few tons of borax per month in 1873, Searles Valley Minerals (SVM) today ships more than 1.7 million tons annually, as well as hundreds of thousands of tons of high-grade mineral products to major manufacturers in 52 countries. These products are used in the manufacture of everything from automobile windshields and laundry detergents, to flat screen televisions, fire retardants and fiberglass insulation.

Mining Solutions

Unlike other mining techniques such as open pit and underground mining, Searles Valley use a unique, ecologically-friendly process called Warm Solution Mining (WSM), wherein a leaching solution—in this case brine—is pumped into the mineral deposit field, where it dissolves the ore content, which is pumped to the surface and processed. The extraction process is made possible in part through a custom-designed, industrial-grade pumping station from Grundfos that accommodates the aggressive and continuously changing brine solution chemistry, not to mention the extreme temperatures that can send the mercury rising to 120-130 F.

“The company’s mining processes are subject to some of the harshest conditions – extreme desert temperatures and caustic solutions – and therefore the pumping systems that support these systems need to be highly reliable and efficient,” recalls Milt Bachman, president of Delta Pump Systems, a California-based industrial distributor specializing in pump design and specifications. “Variable speed pumping combinations had failed the extreme operating conditions in the past, and Searles management was looking for a more dependable, engineered solution.”

The extraction process begins at Searles Dry Lake, a 125-mile square mineral field that contains nearly 200 vertical wells that are fueled by thousands of submersible and vertical turbine pumps that range from 3 to 50 HP and generate nearly 14,000 gpm. The pumps carry thousands of gallons of brine solution from one reservoir or lake bed to another, and the eventual transfer of the mineral-rich brine into holding tanks.

The extraction process begins at Searles Dry Lake, a 125-mile square mineral field that contains nearly 200 vertical wells that are fueled by thousands of submersible and vertical turbine pumps that range from 3 to 50 HP and generate nearly 14,000 gpm. The pumps carry thousands of gallons of brine solution from one reservoir or lake bed to another, and the eventual transfer of the mineral-rich brine into holding tanks.

The application’s unique challenges— both in terms of extreme operating conditions, as well as the required variable pumping volumes— led Searles’ Operations Engineer, David Hakim, to search for a more efficient and cost-efficient solution.

Integrated Approach

Hakim sought out Delta Pump Systems’ Milt Bachman and the Grundfos Engineered Systems (GES) group to help him brainstorm a new, integrated pumping process during the spring of 2012. The GES team works with clients to develop one-of-a-kind, custom-engineered pumping systems that integrate engineering, intelligent controls and the most efficient pump types and technologies available for a specific application.

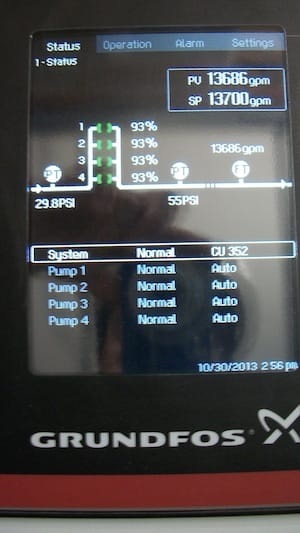

In the case of the Searles Valley Minerals Company, Hakim deployed the Grundfos CU 352 controller to manage the energy efficient PACO horizontal split case pumps, intelligent pump control logic, and the robust Danfoss variable frequency drives. This new pumping station design allowed for the ability to monitor real-time flows, pressures, and temperatures in one location.

“The integrated GES systems approach that SVM envisioned was critical in developing a pumping system that helped increase production reliability, boost mineral yield, and reduce energy costs,” explains Wil Wilkes, regional industrial business sales manager for Denmark-based Grundfos. “Likely the single most important aspect of the new system is the ability to embed the operation’s existing pump curve data to maximize pumping performance and energy use by operating solely at the equipment’s best efficiency point.

In other words, Wilkes explains, because the Grundfos controller “knows” the application’s required flow, as well as the equipment’s optional performance level, the system can make real-time efficiency decisions that can significantly impact energy consumption. For example, the software and integrated monitoring features can instantly determine if it would be more efficient to run two pumps at 50 percent capacity, or one pump at top speed, or any combination therein, Wilkes notes.

According to Wilkes, this competitive advantage allows Grundfos to match pump output with actual demand—without additional external sensors, flow meters and voltage monitors—that for the Searles’ application, was integral in creating an intuitive pumping solution.

Intelligent Pumping Solution

The Grundfos design team drew from multiple pumping technologies in order to deliver a solution to meet SVM’s varying production demands and application conditions.

The pump station ensures the pressure and flow remains constant on a 24/7 basis, operating at 13,800 GPM at 45 PSIG discharge pressure with an inlet pressure of 20 PSIG. The pumping media consists of brine heated to 130F with a 10-12% NaCl concentration, a formula which requires that the pump seals be mechanically flushed regularly with 160-180F solution to eliminate brine crystallization (the media will congeal below 90F).

The main pump skid consists of four 100 HP PACO-brand KP horizontal double suction, split case pumps—each weighing in at more than half a ton—that provide 85 percent design efficiency. The split-case design offers better efficiency and operating performance compared to other designs, as well as easy access to the pump components (bearings, wear rings, impeller, and shaft seal) without disturbing the motor or pipe work. The inboard and outboard mechanical seals remain serviceable without having to remove the top casing. This key design element — servicing the units without interrupting the production process — was pivotal in the team’s selection of this pump series.

In addition to the IEEE 841 severe duty motors to-power the pump station, the system upgrade required the company to install industrial grade coatings for the piping and pump casing and to house the operation in a climate-controlled enclosure to help mitigate high ambient temperatures and hydrogen sulfide gas intrusion. The design team also worked to modify existing piping runs to accommodate the 24-inch-diameter piping and pump headers necessary for the increased volume and additional system monitoring and instrumentation.

“The new industrial pump station provides the necessary operational pressure and flow to inject the brine solution effectively into the salt formation,” said Hakim. “All pumping is controlled and carefully managed to maximize mining production demands and overall efficiencies of the operation.”

Integrated Pressure Boosting System

Ideal for the Searles Valley Minerals application, the BoosterpaQ integrated pumping system utilizes an advanced controller that along with variable frequency drive (VFD) controlled motors, adjust pump speed and number of pumps in operation to meet frequently changing system demand.

At SVM, the BoosterpaQ provides constant pressure with variable flow based on discharge and inlet pressure transducer inputs via PID controlled, 100 HP variable frequency drives. Pumping logic—algorithms and controls—is based on pump performance and become more nuanced with pressure and flow differential.

The overall feedback of the GES system has been overwhelmingly positive thus far. According to Hakim’s analytics, the current savings compared to the previous constant speed pump station is $3,500/month with a two-year payback. “We have set a precedent for future pump stations,” said Hakim.

Join the conversation: