RIDGID®, part of Emerson’s professional tools portfolio, introduces the K9-12 FlexShaft® Drain Cleaning Machine, the latest in a complete line of RIDGID FlexShafts that provide wall-to-wall pipe cleaning power with astonishing speed. The K9-12 is the smallest of the machines and perfect for residential use, eliminating the need to repeatedly unclog the same household drain Read more

Toolbox

RIDGID®, part of Emerson’s professional tools portfolio, introduces the K9-12 FlexShaft® Drain Cleaning Machine, the latest in a complete line of RIDGID FlexShafts that provide wall-to-wall pipe cleaning power with astonishing speed. The K9-12 is the smallest of the machines and perfect for residential use, eliminating the need to repeatedly unclog the same household drain lines.

Clearing up to 30 feet of 1¼-to 2-inch pipe, the K9-12 breaks up grease, hair and other soft blockages, making it ideal for kitchen and bath sinks, as well as tubs and shower drains. Powered by an 1800 to 2500RPM cordless drill, the machine’s chain knocker expands inside the pipe to quickly clear the blockage andrestore the pipe to full flow. A flexible, protective sheath encapsulates the cable, keeping it fully enclosed for less mess and faster cleanup. The built-in clutch design also extends the cable life.

“Our K9-12 FlexShaft Drain Cleaning Machine is a great tool to start with if you have never experienced the cleaning speed and efficacy of a RIDGID FlexShaft Drain Cleaning machine,”said Shelby Gerl, product manager, RIDGID for Emerson. “It will save you time in removing common residential blockages and add value to your work by providing a fully flowing pipe again.”

“Our K9-12 FlexShaft Drain Cleaning Machine is a great tool to start with if you have never experienced the cleaning speed and efficacy of a RIDGID FlexShaft Drain Cleaning machine,”said Shelby Gerl, product manager, RIDGID for Emerson. “It will save you time in removing common residential blockages and add value to your work by providing a fully flowing pipe again.”

The K9-12 joins three additional RIDGID FlexShaft Drain Cleaning Machines–the K9-306, K9-204 and K9-104. Each provides wall-to-wall clean with astonishing speed. Designed for commercial use, the K9-306clears 3-to 6-inch diameter lines up to 125 feet; the K9-204 clears 2-to 4-inch diameter lines up to 75 feet;and the K9-1021¼-to 2-inch diameter lines up to 50 feet.

The K9-12 joins three additional RIDGID FlexShaft Drain Cleaning Machines–the K9-306, K9-204 and K9-104. Each provides wall-to-wall clean with astonishing speed. Designed for commercial use, the K9-306clears 3-to 6-inch diameter lines up to 125 feet; the K9-204 clears 2-to 4-inch diameter lines up to 75 feet;and the K9-1021¼-to 2-inch diameter lines up to 50 feet.

FlexShaft machines are backed by the RIDGID Full Lifetime Warranty.

To purchase or learn more about theK9-12 and entire line of FlexShaft Drain Cleaning Machines, visit RIDGID.com.

Milwaukee is adding eight new shop focused solutions to the PACKOUT™ system, all featuring modularity with the PACKOUT™ Wall Plates. Magnetic Rack—features three magnetic faces, optimized to store hand tools, fasteners, and more for quick access organization Magnetic Bin & Large Magnetic Bin—can be hung on wall plates or stored inside PACKOUT™ organizers, feature a Read more

Milwaukee is adding eight new shop focused solutions to the PACKOUT™ system, all featuring modularity with the PACKOUT™ Wall Plates.

- Magnetic Rack—features three magnetic faces, optimized to store hand tools, fasteners, and more for quick access organization

- Magnetic Bin & Large Magnetic Bin—can be hung on wall plates or stored inside PACKOUT™ organizers, feature a quick access magnetic dish that can be used to organize and store small items like fasteners, power tool accessories, and more. A non-marring magnetic base allows the bins to be stored on metal items without damaging them

- Compact Wall Basket—quick access opening allows for easy retrieval of stored items, 20lb weight capacity perfect for storing gloves, bit cases, and more

- 4” Single Straight Hook & 7-Hook Rack—constructed with metal reinforced hooks to maintain shape when loaded and provide easy placement and removal of stored items

- Belt Clip Rack—constructed with reinforced metal to maintain shape when loaded and optimized to store anything with a belt clip such as knives, tape measures, and more

- Long Handle Tool Holder—optimized to store outdoor power equipment, the quick access tool clamps make it easy to retrieve long-handled tools while the anti-slip rubber grips prevent tools from falling

With the addition of the new PACKOUT™ Shop Storage solutions, the Milwaukee® PACKOUT™ Modular Storage System now has over 75 solutions for users to choose from to fully customize their storage on the jobsite, in transit, and in the shop, making PACKOUT™ the most versatile and durable modular storage system in the industry.

U.S. Boiler Company has introduced the new USB-Connect smartphone application to expedite and streamline installation, service and troubleshooting of all its current and recent condensing and combi boilers. The app, which interfaces with all models of Alta, Aspen, Alpine and K2 boilers through a Bluetooth adapter, allows technicians to access the boiler control via smartphone Read more

U.S. Boiler Company has introduced the new USB-Connect smartphone application to expedite and streamline installation, service and troubleshooting of all its current and recent condensing and combi boilers.

The app, which interfaces with all models of Alta, Aspen, Alpine and K2 boilers through a Bluetooth adapter, allows technicians to access the boiler control via smartphone or mobile device rather than the boiler display.

USB-Connect actively guides boiler technicians with step-by-step start-up, troubleshooting, and service wizards. Start-up wizards include on-phone LP conversion, customer setpoints and other adjustments. Troubleshooting wizards include questions like “Is boiler not running?” or “Is boiler not responding to DHW demand?”, among others. These issues and visible active alarms are often solved with a few taps on the smartphone screen.

The new app features a comprehensive control dashboard, providing instant status, operating details, diagnostic tools, literature and many other resources. All boiler adjustments can be made from the app, including setpoint temperatures, DHW priority, access to error codes, manipulation of fan speeds, configuration of outdoor reset parameters, etc.

The app also provides live software and firmware upgrades and instant, fingertip access to all manuals and documents. Operating details and service records are viewable on- and off-site, and system snapshots can be archived for later use. Should customer service be needed, U.S. Boiler tech support can view the system in real-time when connected through a technician’s smartphone. Jobsite photos can also be posted to the app.

Safe and secure, USB-Connect guides technicians through all service and installation procedures while providing powerful diagnostic tools. This allows technicians to work quickly and accurately, regardless of their familiarity with the product or level of training.

USB-Connect requires only download of the free mobile app and purchase of the USB- Connect Bluetooth adapter kit.

The USB Connect app is available on the App Store (Apple) or the Play Store (Android). For more information, please visit www.usboiler.net

Milwaukee Tool introduces its new M18 FUEL™ Drill and Impact Driver with ONE-KEY™. This expansion of their next-generation drilling and driving solutions, with the new M18 FUEL™ ½” Hammer Drill with ONE-KEY™ and M18 FUEL™ ¼” Hex Impact Driver with ONE-KEY™, delivers users with the fastest driving speeds, enhanced safety, and advanced customization technology. M18 Read more

Milwaukee Tool introduces its new M18 FUEL™ Drill and Impact Driver with ONE-KEY™. This expansion of their next-generation drilling and driving solutions, with the new M18 FUEL™ ½” Hammer Drill with ONE-KEY™ and M18 FUEL™ ¼” Hex Impact Driver with ONE-KEY™, delivers users with the fastest driving speeds, enhanced safety, and advanced customization technology.

M18 FUEL™ ½” Hammer Drill/ Drill Driver with ONE-KEY™

The new M18 FUEL™ ½” Hammer Drill/ Drill Driver with ONE-KEY™ is the most powerful solution in its class, maintaining the highest power under load. Delivering 30% more power, it provides users with less bog down when drilling to improve productivity and efficiency on the job. At just 6.9 inches in length, this hammer drill is the shortest in its class. With a compact, ergonomic design, users are provided more access in tight spaces without the need to sacrifice power.

Milwaukee Tool, M18 FUEL Drill and Impact Driver with ONE-KEY, tools, cordless tools, drill driver, hammer drill

Milwaukee’s new hammer drill also features adjustable AutoStop™ technology to deliver the best-reacting bind-up protection. Designed to prevent over-rotation in application, this new machine learning technology offers adjustable Low, Medium, and High sensitivities to best meet the desired performance, offering users the capability to create customizable RPM settings via the app. As a complete problem-solving solution, Milwaukee’s new hammer drill is integrated with ONE-KEY™ technology, allowing users to sync the tool wirelessly with their mobile device or desktop via the free ONE-KEY™ app. Users can upload data and history to create custom reports, identify where and when the tool was last seen, and track the utilization and service intervals of the tool to maximize uptime and maintain inventory.

M18 FUEL™ ¼” Hex Impact Driver with ONE-KEY™

The new M18 FUEL™ ¼” Hex Impact Driver with ONE-KEY™ is the most powerful in its class, providing users with the fastest driving speeds. Increasing productivity with the ability to drive through a full range of applications, this impact driver delivers 30% more speed than other manufacturers. Featuring a POWERSTATE™ Brushless Motor, users can complete more applications back-to-back without losing speed or power. The M18 FUEL™ ¼” Hex Impact Driver with ONE-KEY™ is designed with ultimate trigger control to improve application control without the need to sacrifice power, while specialized tri-LED lighting provides greater visibility for a brighter workspace. Featuring a machine learning self-tapping screw mode, this impact driver offers custom drive control via in-app customizable RPM settings to deliver ultimate customizable control in application. With integrated ONE-KEY™ technology, Milwaukee’s new impact driver provides users with advanced tool tracking capabilities, allowing customization, tracking, and management via the free ONE-KEY™ app.

Milwaukee is committed to improving productivity by providing performance-driven and trade-focused solutions so users can perform an entire day’s work on one battery system. The M18 FUEL™ ½” Hammer Drill/Driver with ONE-KEY™ and M18 FUEL™ ¼” Hex Impact Driver with ONE-KEY™ are fully compatible with the entire M18™ line, now offering more than 250 power tool solutions.

*M18 FUEL™ is engineered for the most demanding tradesmen in the world. Delivering unrivaled performance, all M18 FUEL™ products feature three Milwaukee®-exclusive innovations—The POWERSTATE™ Brushless Motor, REDLITHIUM™ Battery Pack and REDLINK PLUS™ Intelligence Hardware and Software—that deliver unmatched power, run-time and durability on the jobsite. Simply put, M18 FUEL™ tools are the most powerful 18V cordless tools in their class.

**ONE-KEY™ is the first digital platform for tools and equipment. By integrating industry-leading tool electronics with a custom-built cloud-based program, ONE-KEY™ provides a new level of control and access to information that revolutionizes the way work gets done. The ability to customize, track, and manage through ONE-KEY™ fundamentally changes the way users interact with their tools.

Specifications

M18 FUEL™ ½” Hammer Drill/Drill Driver with ONE-KEY™ (2906-20) – $249.00

- Volts: 18V

- Torque: 1,400 in-lbs

- RPM: 0 – 500 / 0 – 2,100

- BPM: 33,000

- Chuck Type: ½” All-Metal

- Tool Length: 6.9”

- Tool Weight (Without Battery): 3.2 lbs

Includes: 2906-20 M18 FUEL™ w/ ONE-KEY™ 1/2″ Hammer Drill Driver Bare Tool

M18 FUEL™ ¼” Hex Impact Driver with ONE-KEY™ (2957-20) – $199.00

- Volts: 18V

- Torque: 2,000 in-lbs

- Speed: 4-Mode Drive Control

- RPM: 0 – 3,900

- IPM: 0 – 4,400

- Single Hand Bit Insertion: Yes

- Light: Tri-LED

- Tool Length: 4.47”

- Tool Weight (Without Battery): 2.3 lbs

Includes: 2957-20 M18 FUEL 1/2″ w/ ONE-KEY™ Impact Driver Bare Tool

M18 FUEL™ with ONE-KEY™ Two Tool Combo Kit (3696-22) – $449.00

Kit Includes: (1) 2906-20 M18 FUEL™ w/One-Key™ Hammer Drill Driver Bare Tool, (1) 2957-20 M18 Fuel™ w/One-Key ™ Impact Driver Bare Tool, (2) M18™ Redlithium™ XC 5.0AH Battery (48-11-1850), (1) M12™ & M18™ Multi-Voltage Battery Charger (48-59-1812) (1) Drill Side Handle

M18 FUEL™ ½” Drill/Drill Driver with ONE-KEY™ (2905-20) – $239.00

- Volts: 18V

- Torque: 1,400 in-lbs

- RPM: 0 – 500 / 0 – 2,100

- Chuck Type: ½” All-Metal

- Tool Length: 6.9”

- Tool Weight (Without Battery): 3.1 lbs

Includes: 2905-20 M18 FUEL™ w/ ONE-KEY™ 1/2″ Drill Driver Bare Tool

MX FUEL Threading Machine The following information was provided to MH directly from Milwaukee Tool. MILWAUKEE, WI – Milwaukee Tool is resetting the standard in pipe threading performance with the industry’s first cordless threading machine. The new MX FUEL™ Pipe Threading Machine harnesses the power of MX FUEL™ Equipment System’s* REDLITHIUM™ batteries to detach operators Read more

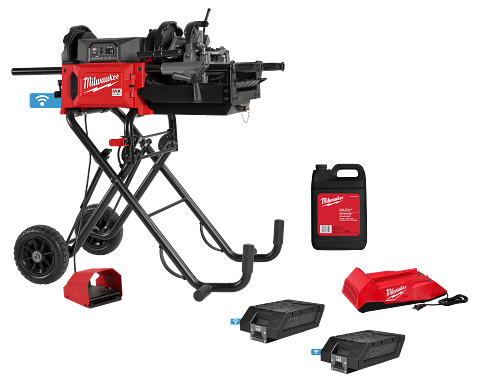

MX FUEL Threading Machine

The following information was provided to MH directly from Milwaukee Tool.

MILWAUKEE, WI – Milwaukee Tool is resetting the standard in pipe threading performance with the industry’s first cordless threading machine. The new MX FUEL™ Pipe Threading Machine harnesses the power of MX FUEL™ Equipment System’s* REDLITHIUM™ batteries to detach operators from power outlets on the job site, allowing threads to be made wherever its most convenient. In addition to the improved design, this new cordless pipe threading machine enables the easiest transportation and fastest set up to clean up, even in remote sections of the jobsite.

“Through our relentless user research, we found clear inefficiencies and significant opportunities to improve job site workflow on jobs requiring large amounts of threading,” said John Karl Jarzombek, Product Manager for Milwaukee Tool. “Historically, corded machines have forced operators to setup and stay near a power source, wasting time walking back and forth on the job site. With the MX FUEL™ Pipe Threading Machine we have freed operators from a power source while also optimizing the design for onsite transportation to enable contractors to move the machine with them as they work. The durable job site cart makes it easier than ever to thread at each point of install or remote areas of the job site and having a self-contained oil reservoir eliminates the need to move messy bucket oilers separate from the machine. All of these innovations ultimately provide operators increased efficiency and the most productive onsite threading experience.”

The MX FUEL™ Pipe Threading Machine comes equipped with the new Milwaukee NPT Pipe Threading Die Head with Micro-Adjust which enables the easiest, most controlled die adjustments and the auto release mechanism controls the thread length. The pipe threading machine is ideal for use with Milwaukee’s new line of Universal Pipe Threading Dies and compatible with other universal style dies.

For easy transportation onto and around the job site, the MX FUEL™ Pipe Threading Machine features a collapsible cart, built with gas springs to assist the tool up to working height and the integrated wheels allow for easy transportation over uneven surfaces. When moving the machine, the self-contained oil reservoir keeps oil within the basin and eliminates the need to drain the oil. Additionally, the reservoir minimizes the mess created by the threading process by removing the need for a bucket oiler, providing the cleanest threading experience available. For jobs requiring threading and grooving, the machine’s rear hammer chuck enables a quick transition and connection of roll grooving attachments without teardown or use of additional adapters. Milwaukee’s pipe threading machine reduces set up and clean up time to under one minute.

Once set up on site, the pipe threading machine provides the power to thread up to 2” black iron pipe, stainless steel, rigid metal conduit (RMC) and more. When paired with the included MX FUEL™ REDLITHIUM™ XC406 battery packs, the threading machine allows for all day runtime, delivering up to (140) cut, reamed, and threaded ¾” pipe ends per pack. Once the job is complete, the machine can be stored upright without spilling, reducing the overall storage footprint.

The MX FUEL™ Pipe Threading Machine joins Milwaukee’s pipe threading tools as another industry first. The machine eliminates inefficient steps of onsite threading and allows the operator to streamline their workflow. The new MX FUEL™ Pipe Threading Machine is fully compatible with the entire MX FUEL™ Equipment System and is a true testament to Milwaukee’s focus on investing in game-changing technology that truly delivers breakthrough solutions for users.

The MX FUEL™ Pipe Threading Machine joins Milwaukee’s pipe threading tools as another industry first. The machine eliminates inefficient steps of onsite threading and allows the operator to streamline their workflow. The new MX FUEL™ Pipe Threading Machine is fully compatible with the entire MX FUEL™ Equipment System and is a true testament to Milwaukee’s focus on investing in game-changing technology that truly delivers breakthrough solutions for users.

In addition, Milwaukee introduces their new line of Universal Pipe Threading Dies, designed for consistent quality threads in pipes. The pipe threading dies are stamped with size markings and alignment numbers for easy identification and allow for quick installation when placed into the die head, maximizing productivity on the jobsite. Offered in alloy, high speed, and high speed for stainless, the Milwaukee Universal Pipe Threading Dies are ideal for use with the Milwaukee® NPT Pipe Threading Die Head w/ Micro-Adjust and the MX FUEL™ Pipe Threading Machine, as well as compatible with other universal die heads.

*The MX FUEL™ Equipment System: This groundbreaking cordless system revolutionizes the light equipment market by delivering the performance, run-time, and durability demanded by the trades without the hazards associated with emissions, noise, vibration, and the frustrations of gas maintenance. Each of the solutions on the MX FUEL™ System go beyond the limitations of gasoline and power-cord units and operate off one completely compatible system all on the same battery. This is Equipment Redefined.

Specifications

MX FUEL™ Pipe Threading Machine (MXF512-2XC)

- Battery System: MX FUEL™

- Pipe Capacity: 1/8” – 2”

- Housing Material: All Metal Construction

- Collapsible Cart: Yes

- Dual Hammer Chucks: Yes

- Micro-Adjust Die Head: Yes

- Self-Contained Oil Reservoir: Yes

- Self-Oiling: Yes

- Equipment Warranty: 2 years

- Battery Warranty: 2 years

- ONE-KEY™ Compatible: Track and Manage

Kit Includes: (1) MX FUEL™ Pipe Threading Machine, (2) MX FUEL™ REDLITHIUM™ XC406 Battery Pack (MSFSC406), (1) MX FUEL™ Charger (MXFC), (1) Gallon Milwaukee Dark Thread Cutting Oil (49-08-5100), (1) NPT Pipe Threading Die Head w/ Micro-Adjust (49-16-5100), (1) ½”-¾” High Speed NPT Universal Pipe Threading Die (48-36-1203), (1) 1”-2” High Speed NPT Universal Pipe Threading Die (48-36-1204)

Milwaukee® Universal Pipe Threading Dies

½”-¾” ALLOY NPT Universal Pipe Threading Dies 48-36-1201

1”-2” ALLOY NPT Universal Pipe Threading Dies 48-36-1202

½”-¾” HIGH SPEED NPT Universal Pipe Threading Dies 48-36-1203

1-2″ HIGH SPEED NPT Universal Pipe Threading Dies 48-36-1204

½”-¾” HIGH SPEED FOR STAINLESS NPT Universal Threading Dies 48-36-1205

1”-2” HIGH SPEED FOR STAINLESS NPT Universal Pipe Threading Dies 48-36-1206

Cutter Wheels for Universal Pipe Threading (4pc) 48-36-1401

Additional Accessories

NPT Pipe Threading Micro Adjust Die Head 49-16-5100

BSPT Pipe Threading Micro Adjust Die Head 49-16-5103

Dark Thread Cutting Oil 49-08-5100

Threading Jaw Inserts for Coated Pipe 49-16-5102

Threading Jaw Inserts 49-16-5104