An Air Admittance Valve (AAV) is a one-way mechanical valve that is installed locally at the site of a plumbing fixture, allowing proper venting to occur without a connection to a larger venting system and stack vent. There are several different AAVs on the market today that all slightly vary in design; however, they each perform the same function.

AAVs present various benefits for contractors and homeowners, particularly when you can’t connect to an existing venting system or are looking to reduce roof penetrations for aesthetic purposes. When installed correctly, they’re a great way to save time, money and frustration.

Before you can effectively select and install an AVV, it’s important to understand how drain-waste-vent systems, known as DWV, work. If you’re a seasoned plumber you might not need this explanation but if you are a new pro entering the industry you might find value in understanding how DWV systems work in relation to venting.

Understanding drain-waste-vent systems

DWV systems consist of drain pipes that provide a network for the removal of waste, as well as vent pipes that prevent unwanted gas from escaping inside the building. Vent pipes also maintain the necessary balance of pressure to allow water to flow.

The DWV system uses gravity and air displacement throughout the piping network to properly function and breathe. In a simplified example, think about the tiny holes on a to-go coffee cup lid that allow air into the container. Without proper air flow, there wouldn’t be enough pressure in the cup for the liquid to flow out evenly, making it very difficult to sip. In order for a liquid to come out, air must come in.

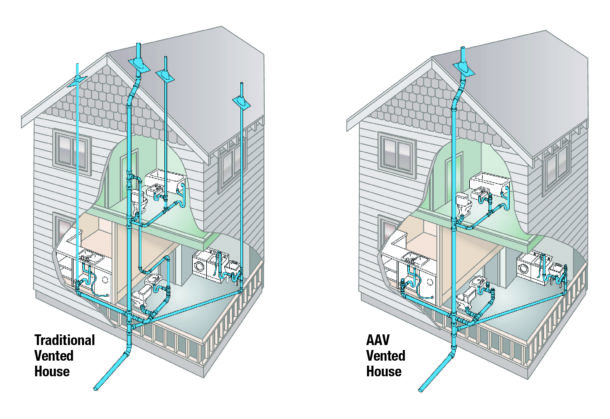

All DWV plumbing systems require at least one vent penetration through the roof line, which allows air to enter the system, while also permitting sewer gas to escape. Connecting all plumbing fixtures in a building to existing venting systems can be complex and limiting. So, you might be asking yourself if there’s a way to bypass this process (and the need for numerous unsightly and expensive roof vent stacks)…cue Air Admittance Valves.

How does an air admittance valve work?

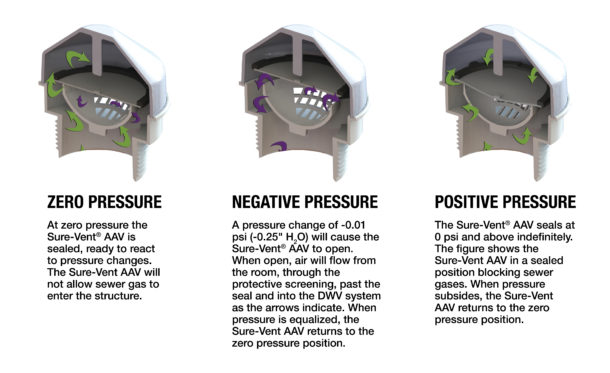

AAVs allow air to enter a plumbing drainage system when negative pressure develops in the piping system (because of the flow of water). When pressure in the system is equalized (indicating that no water is flowing), gravity closes the vent terminal, preventing sewer gases from escaping into a building.

Remember, all buildings must still have at least one stack vent that’s directly penetrating the roof – an AAV doesn’t take the place of that requirement for the building as a whole.

When do you need an air admittance valve?

When you can’t connect to an existing venting system: AAVs are a great alternative if you can’t connect to an existing venting system due to complex pipe routing issues or obstructions – an ideal venting solution for island sinks, remote bathroom groups, home remodels and additions that would otherwise have to be tied into a stack vent utilizing specialized venting techniques. In other words, AAVs allow installers and homeowners more flexibility in the layout of plumbing fixtures.

To reduce roof penetrations: AAVs open and close in conjunction with normal DWV system operation, which eliminates the need to create another roof penetration. Many homeowners prefer not to vent through the roof line for design and aesthetic purposes, too. Additionally, having less roof penetrations can reduce the risk of leaks over time.

To save money: For these reasons, using an AAV requires less labor and supplies, making it a more affordable option than running vent pipe in new construction applications.

Key Considerations when selection and installing an AAV

Local Code and Manufacturer Requirements: Before heading to your local supply house, be sure to check with local municipality codes and manufacturer requirements to determine if an AAV is approved for your particular application. If the use of an AAV is not permitted, the fixture or drainage system will have to be vented traditionally through the home’s existing venting system.

Sizing: You can determine which size AAV you’ll need based on the Drainage Fixture Unit (DFU) load of the fixture(s), such as an island sink or bathroom group, it will vent. An AAV’s ability to breathe is measured in DFUs. The higher the DFU rating on the valve, the greater the amount of air that can enter the Drain-Waste-Vent (DWV) system.

DFU loads are assigned to plumbing fixtures dependent on the volume rate of discharge, the duration of operation and the time between operations. Common fixture load ratings are shown in the table below.

To ensure proper breathing capability, determine all fixtures to be vented and calculate the total DFU load, then select the appropriate AAV for the application. Proper AAV sizing is critical because under-sizing will not allow the plumbing system to operate properly.

AAVs are typically available with 1 ½”, 2”, 3” and 4” adapter connections. The adapter size is based on the diameter of the vent pipe it is being installed on. Generally, a vent should be sized to be half the pipe diameter of the drain it is serving (refer to local codes for specific vent size recommendations).

Pipe material: Additionally, you should verify what type of pipe material you will be connecting the AAV adapter to ensure compatibility. In other words, AAVs with PVC adapters should only be paired with PVC pipe, and AAVs with ABS adapters with ABS pipe.

AAV location: An AAV should be located within the maximum developed length permitted for the vent. It must be located a minimum of 4” above the horizontal branch drain, 6” above any insulation material and within 15 degrees of vertical. AAVs cannot be permanently covered and should be installed in an area that allows air to enter the valve. They must also be accessible, should the need for replacement occur in the future.

Be sure to check with your local municipality before installing an AAV in your plumbing system to confirm the installation will be approved for your particular application.

Guest Author: Jeremy Gattozzi is a Product Manager at Oatey Co., with expertise across a range of rough plumbing products and applications. He is responsible for product research and the delivery of innovative solutions to serve customers’ evolving needs.

Guest Author: Jeremy Gattozzi is a Product Manager at Oatey Co., with expertise across a range of rough plumbing products and applications. He is responsible for product research and the delivery of innovative solutions to serve customers’ evolving needs.

Join the conversation: