Building Information Modeling (BIM) isn't a new concept, but it is definitely one that is gaining greater exposure in the architecture, engineering, and construction (AEC) industry, mainly due to the rapid evolution of technology, and exponential increases of data in the past five years. This uptake of BIM is having a direct impact on the mechanical contracting industry.

Where does the BIM process and momentum begin? It all starts with the designer.

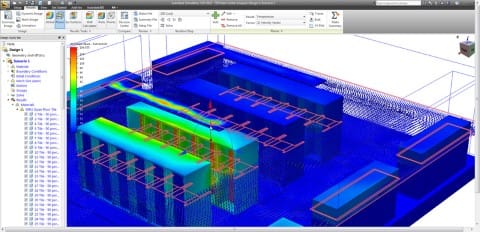

Using intelligent modeling tools like Autodesk® Revit® software products, designers are creating more detailed design models that are rich with data and can be used to engineer more options than previous designing methods. By using the information stored within the model, engineers can optimize for energy efficiency, air flow distribution, and thermal comfort. Computational fluid dynamics (CFD) simulation is on the way to being democratized due to evolutions in technology. Tasks that are computationally heavy used to require expensive hardware and large amounts of computing time, but can now be processed in the cloud using services such as Autodesk® Simulation 360. Designers use these models to visualize and compare different design options, helping them make more informed, better decisions, and influence the selection of mechanical equipment earlier in the design process. As more engineers use intelligent model-based information for simulation, more mechanical contractors are starting their jobs with optimized building designs.

Using cloud-based simulation tools, mechanical engineers can optimize designs for energy efficiency before they get to the mechanical contractor

As a project moves from design into construction, the intelligent model at the heart of BIM continues its journey downstream. These data-rich, optimized models can provide additional benefits to mechanical contractors through the use of fabrication software tools such as Autodesk® Fabrication FABmep™ and Autodesk® Fabrication CADmep™ software. These tools help contractors generate models that are ready for fabrication and installation, with real-world manufacturer-specific content used for both pipework and procurable HVAC components, and fully parametric pressure-class driven items used for manufactured sheet metal ductwork. The resulting model is a near-complete representation of the mechanical, electrical, and plumbing (MEP) systems that can be installed onsite, and can be used to help drive procurement, fabrication, manufacturing, and installation.

The construction model is a near-representation of what can be built onsite, including real-world fixtures and fitting for mechanical systems.

These examples show how BIM is improving the construction of mechanical systems in buildings from design, detailing, coordination, and fabrication perspectives. Yet, there is a bigger story that is currently unfolding around the installation of mechanical systems.

Technological advancement is providing mechanical contractors with new tools to improve the construction process onsite, an area where a large amount of waste has traditionally occurred. The use of the construction model, developed during the mechanical systems detailing and coordination phase of the project, is enabling more precise layout, helping lead to less rework onsite for the client, and better productivity for the mechanical contractor. As these 3D intelligent models are created to be spatially more accurate, data points can be extracted from the model and used with laser positioning devices to improve the accuracy and speed of installation.

Onsite workers use laser positioning devices and data from the 3D model to mark out insertion points before installation. Image courtesy of The Hill Group.

Onsite workers use laser positioning devices and data from the 3D model to mark out insertion points before installation. Image courtesy of The Hill Group.

Then there are field processes that are being reimagined due to the rapid growth of tablets (like the iPad®) in the marketplace and the accessibility of data anytime, anywhere. Apps like Autodesk® BIM 360 Field are helping mechanical contractors redefine field processes such as quality, safety, and commissioning checklists; simplify the distribution of plans and drawings; and enable interrogation of the virtual building model in the physical building environment. Having access to the model helps superintendents visualize queries without having to refer to oversized sheets or make trips back to the office, leading to less RFI’s and better productivity.

Field software, combined with mobile hardware, is helping to redefine onsite processes including commissioning and handover.

In the past, the benefits of BIM were enjoyed primarily by architects and engineers. But today, it is becoming clearer that the benefits and cost savings achieved during fabrication and construction might be just as convincing. As technology advances and software and hardware developments take hold, mechanical contractors' installation processes will continue to be refined and redefined and look to do so for the foreseeable future.

Written by Sam Robins, industry marketing manager, Autodesk.

Join the conversation: