Anyone who has paid even the slightest bit of attention to current industry trends has heard of dry drains, low-flow problems, and the issues occurring in building drainage systems as well as local sewers due to the lack of water flow. Of course, it is important to save water, but at what cost to the performance of the plumbing systems?

Nowadays, with 1-pint/flush and non-water-supplied urinals, dual-flush water closets, low-flow faucets and high-efficiency clothes washers, it is a wonder that any solids ever make it out of the building.

There has to be a balance between water efficiency and proper system function. It is well known, proven and confirmed by studies and research that a trickle of water running through the drainage system is not sufficient enough to carry away solids to the point of disposal. In fact, the Plumbing Efficiency Research Coalition, made up of leading plumbing product, code, engineering and contractor interests, performed a study to research this very issue. According to experts worldwide, one of the most important necessities of proper function is to supply a surge, or volume of water, to flush the drainage system.

Today’s current plumbing codes were created with certain principles in mind. One of the most important aspects of the drainage system sizing criteria is that drainage pipes move solids most efficiently when the pipe is carrying a half-full load of liquid. Although, it is not expected that a drain and waste system will be half full continuously, codes prepare for worst-case scenarios and pipes should be capable of such surges if necessary. Due to today’s bathroom configurations that contain multiple low flow fixtures, it is highly likely that a piping system — at least one sized to current standards — may never flow at a half-full capacity.

Plumbing fixture manufacturers are approaching a crossroads. They need to continue to create new and exciting fixture configurations that save water, yet function properly without deteriorating the integrity of the plumbing system. How much water savings is enough — or too much? The manufacturers have to hit the sweet spot from here on out — that point where they continue to find ways to save more water, yet provide the proper water flow to clear the lines.

The plumbing industry, contractors and engineers, are not just accepting anything that comes along into the plumbing codes. The codes are adapting and requiring additional fixtures or fixture configurations that accommodate the lack of flow through the system. One such example is the requirement that water-free urinals have another fixture upstream to flush any solids or urine salts that may accumulate in the lines due to the lack of liquid flow.

The manufacturer that adapts its product to meet the code provisions and industry needs will survive and prosper. Instead of fighting the code provisions, they should be utilized during the design phase. Instead of being at odds with the tradespeople responsible for maintaining the health and safety of the public through sound plumbing principles, listen to their reasoning.

For years, there has been a struggle within the code development hearings between waterless urinal manufacturers and code stalwarts. The tradesmen would point out that the urinals would accumulate salts and sludge that would cause odors and stoppages and result in the eventual replacement of either the lines or the fixtures. The manufacturers’ representatives would dig their heels in and argue that it is a maintenance issue, not a fixture function issue, and therefore was not a problem to be corrected through the code process.

If you have ever been to any IAPMO code development hearings in the past decade, you will recall that non-water-supplied urinals are always a hot topic of discussion and debate. The manufacturers’ consultants would vigorously debate with the inspectors and installers. The arguments against were usually centered around drain line carry, uric salt build up in the lines, odors, sanitary conditions and even disease spread. Although some of the arguments were unfounded, some had real merit. Even though the story was the same year after year, hearing after hearing, there was not much change by the manufacturers to accommodate the opponents’ arguments…until recently.

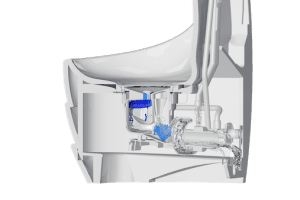

In a partnership with Sloan Valve Co., Falcon Waterfree Technologies, one of several manufacturer participants in the aforementioned code debates, recently introduced a new “hybrid” urinal at the ASPE Expo in Chicago. A hybrid urinal is defined in the IAPMO Standard IGC 311-2014 as — a urinal that (a) conveys waste into the drainage system without the use of water for flushing; and (b) automatically performs a drain‐cleansing action after a predetermined amount of time. The urinal introduces 1-gal. of water to the exit of the water-free trap cartridge every week. That means it uses a set 52-gal. per year. This is a particularly clever adaptation of a typical waterless urinal in that it takes the arguments of the opponents of non-water-supplied urinals and answers their objections.

The 2015 Uniform Plumbing Code, if accepted with the changes submitted thus far in the process, will require a fixture upstream of non-water-supplied urinals to flush the drain line and reduce any uric salt or crystal build-up. This Sloan Valve/Falcon Waterfree “hybrid” urinal now incorporates a surge of water on timed intervals to cleanse the fixture drain as well as the lateral line, thus eliminating the need for an upstream fixture. It also redirects the urine from the bottom of the cartridge through a pour-type spout on the side to minimize splash, where settlement and build-up is initiated in current designs.

This is an example of hitting the sweet spot! One must be experienced enough to recognize when and where code opposition should be vigorously defended and when it should be tempered with practical solutions. It might be imperative to send a code expert, whether staff or a specializing consultant, to defend against “code attacks,” especially an obvious attempt to limit your product’s use. If so, don’t overlook the opportunity to listen to the opposition and study the possibilities to revamp or reengineer. Listen closely to the experts participating in the code development process, even the opposition. It could just be a signal that it is time to take advantage of the code development process, invest in research and development, and take a giant leap ahead of the competition.

This is the future of plumbing fixture and component manufacturing. Listen to the industry, understand the codes, and find that sweet spot where the product uses water efficiently while safely working in concert with the plumbing system, whether new or existing. A surge through the system, not a trickle. Such a simple solution, who would have imagined…?

Jay Peters, Codes and Standards International, assisted Falcon Waterfree technologies in standards writing, testing and certification for the Hybrid Urinal. He has more than 30 years in the industry and recently held senior staff positions at the International Code Council and the International Association of Plumbing and Mechanical Officials. He now advises manufacturers in the area of product certification, testing, codes, standards and advocacy. He can be reached at peters.jay@me.com or www.BuildingCodesAndStandards.com.

Join the conversation: