Elder care is an ever-increasing area of growth for the businesses that serve it. This holds true for all segments of the market, from 55+ communities to hospice facilities. America is aging, and there’s no place in the country not affected by the retirement of the Baby Boomer Generation.

This predicament is a boon to the contractors who’re poised to capitalize on it. New elder care facilities are cropping up everywhere, and existing buildings are being retrofitted at a blistering pace. But the scope of work can be a far cry from residential work. The nature of these projects, and the colossal amount of money involved, typically demands uncompromising quality of work and compact timelines.

Like most medical facilities, redundancy in mechanical systems at a retirement facility are a must. The best components are used and designs are very carefully scrutinized. Few mechanical contractors understand this market and its challenges better than Dominick Fausto Sr., third-generation master plumber and owner of Absolute HVAC in Farmingville, NY. Absolute provides design-build hydronic solutions to New York City. Now in his 40th year in the trade, about half of Fausto’s work is commercial.

“Assisted living facilities and hospitals account for a lot of our work, both on the installation and service side,” said Fausto. “We’ve retrofitted two large systems in the past 10 months or so.”

Much like finding good technicians, Fausto says that finding good customers in New York City can be problematic. In years past, doing great work at a good pace was enough to keep a customer for decades. But the current fluidity in the health care industry – whether through employee turnover or mergers and acquisitions – mean that long term customers are scare, regardless of how dependable you are. With that said, Absolute HVAC still nurtures some relationships forged long ago.

Fausto’s most loyal customer owns countless retirement and medical facilities in numerous states, and has trusted Absolute HVAC for 39 years. As the man’s empire slowly changes hands to his children, he’s insistent that the trust between the two companies remains intact.

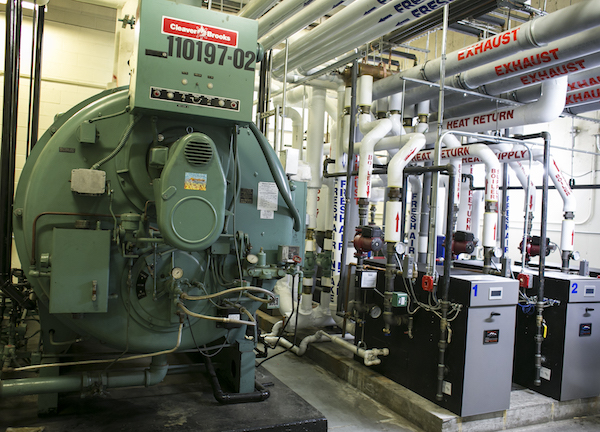

Turning the tables: Burnham Alpine boilers now heat the building and provide DHW, but one scotch marine boiler was left in place for back-up.

“You wish all your customers were like this gentleman,” said Fausto. “We’ve given him our best for many years, and he appreciates it. No matter which one of his buildings we’re working on, he wants all of his systems to be built and maintained without compromise. And he means it.”

Most recently, Absolute HVAC technicians, lead by Field Supervisor Darnell Coleman, found themselves retrofitting the boiler system at the Elmhurst Care Center, in Elmhurst, N.Y. The 410-bed nursing home in Queens was named one of the best in the nation by US News and World Report, a reflection of great health inspections, nursing staff and medical care.

Redundancy and efficiency

The 11-story building was constructed in 1997, but before the walls went up, two massive, scotch-marine boilers were craned into the basement. The gas boilers were each rated at 6.28 million BTU/H. The boilers and everything else in the cavernous mechanical room, including a pair of 10-HP base-mounted pumps, were completely redundant.

The new Alpine Boilers, at 95% thermal efficiency, should save the facility more than 40% on natural gas expenses.

Field Supervisor Darnell Coleman checks electrical connections on one of six Burnham Alpine boilers.

Absolute HVAC installed the original boilers 20 years ago, and has serviced it since. So when the call came to replace one of the units, Fausto was already intimately familiar with the whole system. His suggestion was to use a high-efficiency alternative to replace one of the redundant units, and leave the other big boiler in place as backup.

Over the course of a few weeks, Fausto worked with US Boiler’s northeast regional director, Chris Massey, and some of the pros at Venco Sales Inc. to design a condensing boiler system for the building. Once completed, the design was approved by an engineer of record and a demo team was soon onsite to remove one of the big fire tube boilers.

“With Massey and the guys at Venco, we have a great support network,” said Fausto. Chris McCorvey is lead service tech at Venco, and he was onsite for startup. Jake Greenwood and Frank Brecher were instrumental when it came time to specify equipment.

Absolute HVAC technicians started by extending the concrete boiler pad and rolling six new Burnham Alpine modulating boilers into the mechanical room. At 95 percent AFUE, the Alpine’s onboard Sage control simplifies integration of numerous boilers into one larger system.

“Six years ago we made the Alpine boiler our primary condensing unit,” said Fausto. “It’s extremely dependable, very easy to install and service, and comes in such a broad size range that it can be installed in a salt box home or, as you see here, a massive commercial application.”

The 800 MBH boilers are daisy-chained in a lead/lag configuration, effectively giving the facility a 30-to-1 turndown. The new condensing system heats the entire structure as well as providing domestic hot water through the use of three, 120-gallon, high-recovery Techtanium instantaneous indirect-fired water heaters. The remaining scotch-marine boiler sits cold, and would only be needed in the event of a catastrophic failure.

The height of the building demands an extremely high system pressure, so the boilers are isolated from the building via the use of two Alfa Laval plate-and-frame heat exchangers. The heat exchangers connect the four-inch boiler loop to the six-inch system loop.

Throughout the building, bedrooms are heated by PTAC units featuring a hydronic coil. Lobbies and various common spaces are conditioned with fin-tube baseboard, and a few recreation areas feature hydronic air handlers.

The height of the building demands an extremely high system pressure, so two plate-and-frame heat exchangers are used to isolate the boiler and building loops.

With a solid design and ample support from Venco, the installation progressed smoothly. The only challenge came when it was time to run vent pipe. Two 18-inch thick walls required core drilling to terminate the six, four-inch fresh air intakes and six, six-inch exhaust pipe.

“Within four weeks we had half the new boilers up and running,” explained Fausto. “After another four weeks, the whole system was online. I think that a 40 percent energy savings this winter is a conservative estimate. We did a similar installation with three Alpines in an assisted living facility for the same client last fall and saw a 42 percent reduction in fuel use over the heating season.”

All six boilers will run at 65% capacity when the outdoor temperature reaches 38°F. So far, the proof of Absolute’s work has come from the inspector and from the building occupants. Since the retrofit, they’ve not received a single domestic hot water complaint.

The retrofit at the two retirement facilities is part of a larger effort the owner is making to help his children move smoothly into a leadership role at the company. He wants to leave them with as much updated infrastructure as possible. And for the projects that don’t take place be for he retires, Absolute HVAC will still be in business.

Join the conversation: