The REHAU EVERLOC+® compression-sleeve fitting system has 26 additional configurations making transitions between pipe sizes more convenient in plumbing and hydronic piping. The system comprises RAUPEX® PEXa pipe in 3/8 to 2-in. diameters, polymer and lead-free brass fittings and power tools for reliable, safe and cost-competitive connections. Designed for no-leak security, the two-step fitting expansion Read more

Products

The REHAU EVERLOC+® compression-sleeve fitting system has 26 additional configurations making transitions between pipe sizes more convenient in plumbing and hydronic piping. The system comprises RAUPEX® PEXa pipe in 3/8 to 2-in. diameters, polymer and lead-free brass fittings and power tools for reliable, safe and cost-competitive connections. Designed for no-leak security, the two-step fitting expansion and compression process is performed quickly in any weather, making installation faster than copper and other PEXa cold-expansion fittings. The NSF/ANSI 14&61-certified system delivers safe drinking water with no mineral build-up and is backed by a 25-year limited warranty.

The REHAU EVERLOC+® compression-sleeve fitting system has 26 additional configurations making transitions between pipe sizes more convenient in plumbing and hydronic piping. The system comprises RAUPEX® PEXa pipe in 3/8 to 2-in. diameters, polymer and lead-free brass fittings and power tools for reliable, safe and cost-competitive connections. Designed for no-leak security, the two-step fitting expansion and compression process is performed quickly in any weather, making installation faster than copper and other PEXa cold-expansion fittings. The NSF/ANSI 14&61-certified system delivers safe drinking water with no mineral build-up and is backed by a 25-year limited warranty.

NIBCO Inc. announced the launch of our new tailpiece (PC634) pipe joining component. This product is designed for use in multiple applications which include connecting to inlets or outlets for plumbing and mixing stations used to regulate radiant heating supply water temperatures. “This launch continues our commitment to ongoing product development to help contractors and Read more

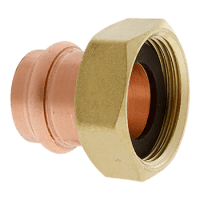

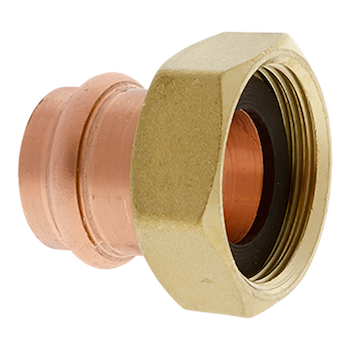

NIBCO Inc. announced the launch of our new tailpiece (PC634) pipe joining component. This product is designed for use in multiple applications which include connecting to inlets or outlets for plumbing and mixing stations used to regulate radiant heating supply water temperatures.

NIBCO Inc. announced the launch of our new tailpiece (PC634) pipe joining component. This product is designed for use in multiple applications which include connecting to inlets or outlets for plumbing and mixing stations used to regulate radiant heating supply water temperatures.

“This launch continues our commitment to ongoing product development to help contractors and homeowners take advantage of high-quality products and over 100 years of innovation in the joining industry,” said Marilyn Morgan, Senior Product Manager. “The PC634 tailpieces are a superior choice for pipe joining in heating systems as well as baseboard and fan coil applications.”

Other applications for the tailpieces include use with mixing valves, diverting valves and other plumbing devices or equipment in potable water and heating systems requiring a straight thread union connection.

NIBCO press fittings are made with 100% North American pure copper which is a premium, proven and preferred material for plumbing and mechanical applications. Manufactured in our Stuart’s Draft, Virginia facility, the tailpieces are convenient to use and part of our commitment to high-quality flow control products and manufacturing services.

Tailpieces (PC634) are third party certified to ASME B16.51, UPC and PS-117.

The new C-634RB1 heavy duty commercial hydrant round box is the answer to long and arduous hydrant box installations. This product was designed to simplify the process for plumbers, while maintaining the durability and finish of a traditional PRIER hydrant box. “A plumbers’ time is valuable, and they have always praised how easy it is to install our Read more

The new C-634RB1 heavy duty commercial hydrant round box is the answer to long and arduous hydrant box installations. This product was designed to simplify the process for plumbers, while maintaining the durability and finish of a traditional PRIER hydrant box.

The new C-634RB1 heavy duty commercial hydrant round box is the answer to long and arduous hydrant box installations. This product was designed to simplify the process for plumbers, while maintaining the durability and finish of a traditional PRIER hydrant box.

NIBCO INC. announced that it has filled out its line of hydronic heating press-connect fittings, including two types of elbows and a fin tube stiffener. The additions include forged bronze vent elbows, a wrot copper extended elbow and a wrot copper fin tube stiffener. All of the products are lead-free. The PC-705-D forged bronze Press Read more

NIBCO INC. announced that it has filled out its line of hydronic heating press-connect fittings, including two types of elbows and a fin tube stiffener. The additions include forged bronze vent elbows, a wrot copper extended elbow and a wrot copper fin tube stiffener. All of the products are lead-free.

NIBCO INC. announced that it has filled out its line of hydronic heating press-connect fittings, including two types of elbows and a fin tube stiffener. The additions include forged bronze vent elbows, a wrot copper extended elbow and a wrot copper fin tube stiffener. All of the products are lead-free.

The PC-705-D forged bronze Press x Press 90° vent elbows are available in ½-inch and ¾-inch sizes. The vent elbows have been specifically designed for use in hydronic heat applications. They comply with the performance standards of ASME B16.51 and are third-party certified to UPC and PS-117. The elbows have an operating pressure 200 PSI and a temperature range -20°F to 250°F.

The PC607E-2 wrot copper 6-inch extended elbow comes in a ¾-inch Fitting x Press connection on a 90° elbow. The extended elbow has been specifically designed for use in heating applications to provide a clean transition through the floor or wall. The elbows have an operating pressure 200 PSI and a temperature range -20°F to 250°F.

The extended elbow is third-party certified to ASME B16.51, UPC and PS-117.

The wrot copper ¾-inch fin tube stiffener ensures secure connections with the extended elbow.

The NIBCO leak detection system identifies uncrimped connections during system testing. When properly crimped a unique “N” witness mark is clearly visible. The NIBCO® Press System® includes a complete line of fittings, valves, accessories and pressing tools.

Our copper press fittings, including our new extended elbow and fin tube stiffener, are manufactured in our Stuarts Draft, Virginia, facility from 100% North American pure copper. NIBCO has been manufacturing metal plumbing fittings in the United States since 1927.

BLÜCHER announced plans to showcase its food safety solutions – HygienicPro® channels and drains and the HygienicClean™ channel and grating washer—in Booth B8339 at the International Production & Processing Expo (IPPE) in Atlanta, February 12-14. The innovative design of HygienicPro drains provides high flow rates that allow easy cleaning with minimal water requirements. The HygienicClean Read more

BLÜCHER announced plans to showcase its food safety solutions – HygienicPro® channels and drains and the HygienicClean™ channel and grating washer—in Booth B8339 at the International Production & Processing Expo (IPPE) in Atlanta, February 12-14.

BLÜCHER announced plans to showcase its food safety solutions – HygienicPro® channels and drains and the HygienicClean™ channel and grating washer—in Booth B8339 at the International Production & Processing Expo (IPPE) in Atlanta, February 12-14.

The innovative design of HygienicPro drains provides high flow rates that allow easy cleaning with minimal water requirements. The HygienicClean simultaneously cleans the HygienicPro channel and grating in a single process, without removing the grating.

With their easy-to-clean smooth surfaces, these stainless steel drainage solutions are changing the way food processing facilities meet stringent safety requirements.

For more information, visit www.blucher.com.