Uponor BIM Services is the best way to deliver high-quality models to optimize efficiencies in your construction projects. Partnering with the knowledgeable professionals of Uponor BIM Services provides your projects with expert modeling and coordination, laser scanning, BIM coordination management, BIM training for your staff, onsite collaboration, template development, and workflow optimization. This U.S.-based team Read more

Products

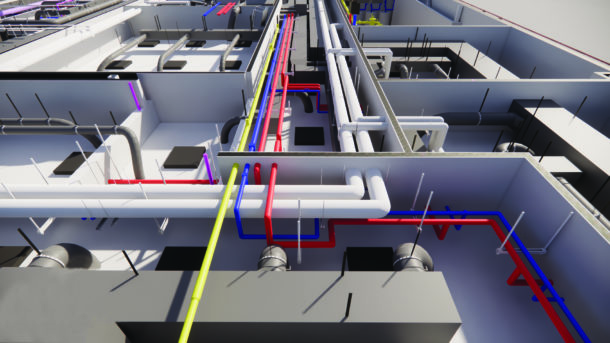

Uponor BIM Services is the best way to deliver high-quality models to optimize efficiencies in your construction projects. Partnering with the knowledgeable professionals of Uponor BIM Services provides your projects with expert modeling and coordination, laser scanning, BIM coordination management, BIM training for your staff, onsite collaboration, template development, and workflow optimization.

This U.S.-based team has in-depth understanding of U.S. codes and standards as well as direct experience with U.S. construction methods. Services are available for numerous applications, including domestic water; drain, waste, and vent; gas; medical gas; ductwork; refrigerant systems; and heating hot water and chilled water applications. Additionally, the team can work with all material types and connections for PEX, PP-RCT, CPVC, carbon steel, copper, stainless steel, and cast iron.

For modeling and coordination, Uponor BIM Services provides hanger layouts and structural supports, spooling and fabrication detailing, and shop, install, and as-built drawings. They also provide laser scanning services, including scanning of existing buildings for renovation, scanning completed projects for documentation, and scan-to-BIM services.

Incorporating laser scanning captures extraordinary detail of 3D spaces to measure areas with greater precision. This allows you to identify issues early on to maximize efficiencies and minimize waste. For example, you can leverage the 3D models from a laser scan to validate details from the onset of design to improve overall project execution and collaboration. This leads to reduced design errors, which result in higher design accuracy that saves money and time by reducing rework and change orders.

From there, benefits multiply during construction as higher-quality designs increase job-site productivity. Specifically, well-coordinated designs lead to improved job costing through accurate quantities and estimates, resulting in reduced waste. This saves your project money, resources, and time.

Finally, site logistics can be more precise by leveraging accurate models to create model-based schedules or sequences. Look-ahead plans, work-in-progress models, materials planning, equipment and rigging locations, site traffic patterns and controls, and even location-based schedules can be derived from well-coordinated 3D models to optimize daily job-site activities.

To learn more about how Uponor BIM Services can maximize efficiencies for your projects, visit uponor.com/en-us/construction-services/bim.

Explore how the new Resideo Magnetic Hydraulic Separator boosts boiler efficiency and protects modern hydronic installs through air, debris, and ferrous removal, as well as critical flow management between connected hydraulic circuits. All of which makes it easier to deliver comfort and efficiency while helping minimize callbacks. https://youtu.be/DlNXFVd3tc4 Designed to simplify boiler piping for critical Read more

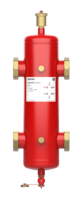

Explore how the new Resideo Magnetic Hydraulic Separator boosts boiler efficiency and protects modern hydronic installs through air, debris, and ferrous removal, as well as critical flow management between connected hydraulic circuits. All of which makes it easier to deliver comfort and efficiency while helping minimize callbacks.

Designed to simplify boiler piping for critical flow management between connected hydraulic circuits, these separators help keep the boiler and heat emitters clean as the dirt and magnetite are gathered in the separator, improving heat transfer with air removal.

For more hydronic solutions visit Resideo.

PRIER Products, Inc., a leading manufacturer of brass plumbing products, launched another unique product today. The new irrigation valve, P-6IV comes with a built-in elbow that swivels to allow for easy installation and reduced cost for extra parts. It’s also designed with the homeowner and contractor in mind that allows servicing from the exterior of Read more

PRIER Products, Inc., a leading manufacturer of brass plumbing products, launched another unique product today. The new irrigation valve, P-6IV comes with a built-in elbow that swivels to allow for easy installation and reduced cost for extra parts. It’s also designed with the homeowner and contractor in mind that allows servicing from the exterior of the structure, rather than entering the residence.

Most installations require the contractor to enter the home to drain down the system for winterization. The new valve from PRIER can be accessed from the outside, which means the homeowner doesn’t need to be home or provide access to the contractor for annual servicing.

“The new irrigation valve is another one of our innovations to our full line of exterior plumbing products,” said Research and Development Manager, Scott Brady. “Our engineering team worked hard to perfect the design which has similar characteristics to another one of our top-of-the-line valves.”

The heavy-pattern cast brass hydrant with a nickel-plated body looks attractive, resists corrosion and should last the life of the plumbing system when installed correctly. The valve also offers a patented triple-seal positive shutoff system. The triple-check assures shutoff.

“We’re excited to launch this new irrigation valve. The innovative design makes installation and servicing easier for contractors and homeowners alike,” said President, Nick Manning. “This is one of several new products in development this year.”

The new P-6IV is available in 12 lengths to suit a wide range of installation needs across the United States and Canada.

Refrigerant lines are push fit into Quick Connect fittings within seconds without brazing, flaring or expensive crimping connection tools RectorSeal®, Houston, a leading manufacturer of quality HVAC/R equipment, has added the Quick Connect push-fit, flame-free, refrigerant line brass fitting system to its PRO-Fit™ tools and accessories product line for the North America and Australia markets Read more

Refrigerant lines are push fit into Quick Connect fittings within seconds without brazing, flaring or expensive crimping connection tools

RectorSeal®, Houston, a leading manufacturer of quality HVAC/R equipment, has added the Quick Connect push-fit, flame-free, refrigerant line brass fitting system to its PRO-Fit™ tools and accessories product line for the North America and Australia markets. Quick Connect is the new generation of refrigeration pipefitting designed for ductless mini-split and ducted unitary single-family residential air conditioning systems. It’s the HVAC/R industry’s only refrigerant fitting system not requiring flaring, brazing or expensive crimping connection tools.

After cutting, deburring and marking for proper depth, the refrigerant line installation requires less than five seconds to push into the fitting until the depth marking appears in the sight glass. Each Quick Connect fitting port consists of a patented factory-assembled tight-fitting double O-ring, protector, grip ring and an endcap–none which the installer needs to address.

No special tools are required except for a reusable, inexpensive support kit that’s sold-separately and consists of a universal five-diameter pipe depth marking tool and five sizes of horseshoe-shaped release clips that disengage a connection within seconds.

Quick Connect comes in five fitting types–union, 90° elbow, reducer, 90°elbow reducer and socket–and the four most common lineset diameters of 1/4-inch (6-mm), 3/8-inch (9-mm), 1/2-inch (12-mm), and 5/8-inch (16-mm). Quick Connect also includes 3/4-inch (19-mm) and 7/8-inch (22-mm) sizes, but only for union and 90° elbow styles.

Quick Connect is UL certified and third-party tested under UL 157, UL 203, UL 250 and UL 1963. Passed test conditions include long-term helium leak, vibration, burst pressure, tensile strength, reusability, salt spray, fatigue, chemical compatibility and six other reliability tests. Quick Connect fittings accommodate system pressures up to 870-psi and are designed for both HCFC and HFC refrigerants–R-22, R-410A, R-744, R-134a, R-407A, and R-507.

Other Quick Connect features are:

- Double O-rings’ leak-resistant elastomeric materials are specifically designed and third-party certified under UL 157 test standard for minimal shrinkage (less than one percent) and swelling in R-410A/POE oil refrigeration systems;

- Service valves (1/4, 3/8, 1/2 and 5/8-inch) are available on an OEM basis;

- Reducers and 90° elbow reducers step down from 5/8 to 1/2-inch, 1/2 to 3/8-inch, 3/8 to 1/4-inch line sizes;

- Ideal for copper as well as coated aluminum refrigerant lines;

- Separate depth marking and release clip tools are available for each the 3/4 and 7/8-inch diameter fittings.

- A four-color 14 (w) x 8 (d) x 8 (h)-inch (35.5 x 20 x 20-cm) wholesale counter display where contractors can push-fit a pipe into a fitting and use the release tool to disengage it;

- The 26-sku system is packaged in individual cardboard hangtag see-through bags;

- Five-year warranty;

For more information on Quick Connect or other PRO-Fit and RectorSeal products, please visit www.rectorseal.com email: marketing@rectorseal.com; or call 800-231-3345.

The Laars Heating System Commercial Tankless Electric H Series (Formerly HL) are Built to be the Best®, offer industry-leading heating capacity, durability, and precision. The H Series is suited for a variety of commercial markets including schools, hospitals, sports facilities, and restaurants. The Laars H Series includes various single phase and 3-phase voltage selections, low-watt Read more

The Laars Heating System Commercial Tankless Electric H Series (Formerly HL) are Built to be the Best®, offer industry-leading heating capacity, durability, and precision. The H Series is suited for a variety of commercial markets including schools, hospitals, sports facilities, and restaurants. The Laars H Series includes various single phase and 3-phase voltage selections, low-watt density incoloy 800 sheathed elements, minimal pressure drop, LED touch pad, PID temperature control, NEMA 4 enclosure (standard for 25kW model, optional for others), a bi-metal manual reset, and an optional 0.15 GPM low flow activation.

Whether you need intermittent hot water, low flow control, booster heating or deionized water in schools, hospitals, or commercial kitchens, we have an energy efficient commercial tankless water heater that provides precise temperature control.

Standard Features

- PID Temperature Controller

- Incoloy 800 Elements

- Low Watt Density Element

- Liquid-Cooled Triac Switches

- Bi-metal Manual Resets

- NEMA 1 Enclosures

- Recirculation Capable

- Simple Touch Operation

- Wall-mounted

- 3/4″ connections

- Easy to Install

- Reliable Performance & Minimal Maintenance

- ETL (Edison Testing Labs) Certified to UL Standards

kW Range: 5 – 25 kW

Flow Range: 0.5 – 7 GPM (1.9 – 26.5 L-Min)

Standard Voltages: 208V, 240V, 277V, 480V Single Phase | 208V, 240V, 480V 3-Phase Delta

Learn more at https://www.laars.com/products/h-series