As a contractor, you’re always looking for ways to do a job faster without compromising quality. Completing jobs in the estimated time (or faster) allows a company to take on more work and earn more revenue while keeping clients happy. Conversely, taking longer than expected results in fewer jobs completed, less revenue, and unhappy clients Read more

Guest Blog

As a contractor, you’re always looking for ways to do a job faster without compromising quality.

Completing jobs in the estimated time (or faster) allows a company to take on more work and earn more revenue while keeping clients happy. Conversely, taking longer than expected results in fewer jobs completed, less revenue, and unhappy clients.

And the margin of profitability is slim.

Consider this estimate for a simple residential water heater replacement:

- Installation billable hours 1.5

- Hourly break-even rate $300

- Labor + 35% net profit margin (NPM) $692

- Materials $575

- Materials + 35% NPM $885

- Total Flat Rate Price (FRP) $1577

But what if the installation takes two hours instead of 1.5 hours? That’s only an additional 30 minutes, but it eliminates nearly two-thirds of the original net profit (or $150).

This need for speed is one of the reasons pressing is replacing soldering and welding as the preferred way to join pipe. Pressing delivers a 30% to 90% time savings for ½” to 4″ connections, depending on the material. Connections can be made in as quickly as seven seconds or less.

Pressing saves time in other ways as well. It connects when wet so there’s no need to drain the system. Since no flame is required, setup is minimal and free of worries about fumes and venting. The need for burn permits and fire watches is eliminated. Less equipment also means less time lugging it to and from the worksite.

Not only does press technology save time (and money) on the job; the most significant savings may be upfront. The technology is simple. Position the tool and press a button – it’s really not much more complicated than that. Teaching a tech to solder or weld requires far more training and investment on the part of the company. With less training required for pressing, techs can get into the field sooner and start completing jobs. All of which saves the company money.

And without the need to hire or train certified welders it’s easier for a contractor to recruit and deploy workers, an important edge when hiring in the trades nowadays.

Viega introduced its press technology in Germany in 1989 and brought it to North America in 1999. In the two decades it’s been in use here, it’s been steadily winning converts. It can be used to connect everything from copper and steel to PEX and stainless steel and can be used in industrial, commercial and residential applications.

Pressing is not only faster than soldering and welding, it’s also more reliable. Viega’s press systems remove the variables found in traditional methods of pipe joining and stabilize the labor required to install. For even greater confidence, Viega’s Smart Connect® technology easily identifies un-pressed connections during pressure testing.

Still need some convincing that pressing can mean the difference between losing and earning money? Here’s another example of adding a gas line for a new cooktop:

Billable hours to route 20’ through crawlspace to range 3.0

- Hourly break-even rate $300

- Labor + 35% NPM $1384

- Materials $60

- Materials + 35% NPM $93

- Total FRP $1477

What if the installation takes two hours longer than estimated because the crawlspace is full of junk? That’s a labor loss on the job and $923 left on the table. Pressing pipe can’t unclutter a crawlspace, but it is a smart way to keep time on your side.

Bo DeAngelo is Manager, Technical Training, at Viega LLC.

Bo DeAngelo is Manager, Technical Training, at Viega LLC.

Measuring tools are a vital tool in nearly every trade and every phase of construction. Measuring tools are often both the first step and the last step in completing jobs on the worksite. Whether a contractor is using a cross-line laser to align electrical outlets or an estimator using a laser distance measure to calculate Read more

Measuring tools are a vital tool in nearly every trade and every phase of construction. Measuring tools are often both the first step and the last step in completing jobs on the worksite. Whether a contractor is using a cross-line laser to align electrical outlets or an estimator using a laser distance measure to calculate area for flooring, nearly all trades are increasing usage of measuring tools. In turn, this increases the need for manufacturers to produce tools that offer enhanced precision, extra durability, and fit into more use cases than ever before. From plumb bobs to box lasers to chalk lines, measuring tools have seen perhaps the largest shift out of any other category of power tools.

Overall, measuring and leveling has become a faster, easier, and more affordable process than ever before. One way to think about the evolution of measuring tools is to compare it to the evolution of cell phones. When we look back at the very first cell phone, its purpose was to make calls. Now, cell phones offer much more than simply the ability to place a call. There’s consistently new iterations of cell phones, updates to applications, and new capabilities that enable users to do more with one device and do it more efficiently. Similarly, we are continually learning about new ways that measuring tools are being used on jobsites, offering us insight on how to make these tools as useful as possible.

For starters, the laser technology used in measuring tools has improved tremendously with the shift from red beam lasers to green beam lasers in the past five years or so. Green is a color more visible to the human eye and thus scientifically, we can see the green beam laser better than red. In some environments where you might have ambient light shining onto the workspace, having additional visibility on the job site and longer ranges of laser light to work with is vital.

We have also seen a shift in producing measuring tools to be more compact, yet more durable, than ever before. As a direct result of listening to user feedback, manufacturers have begun to ensure that a measuring tool on the jobsite is built just as tough as the job itself, but also compact enough to ensure portability. We now see measuring tools that can fit in a tool belt or a case that is easily transported on a person, or alongside them as they move through their day. And it’s worth mentioning that these newer compact tools still carry great accuracy in their small package.

With the measuring tools market expanding to serve increasingly more trades and industries, we have also seen additional capabilities arise depending on the use. For example, a new high-end rotary laser might now offer UCAL, or user calibration. This is a way to connect the tool to a smart device and allow the user to calibrate their laser on site. This is especially useful in cases where a rotary laser, which is stood upright, can potentially get knocked out of place or slightly shifted. With UCAL, users can do their own accuracy check to ensure they are always working off of a level benchmark. Another similar tool capability on the rise is the option for connectivity, which has become an absolute necessity in the measuring tools category. Added connectivity to smart devices allows users to document their work digitally and immediately transfer detailed and accurate measurements off to a coworker or an office. The ability to document measurements in this way has created meaningful ecosystems and provided insight into how manufacturers can make measuring tools even more useful and accurate, and ultimately increase productivity on the jobsite.

Overall, throughout the past 5-10 years measuring tools have become more accurate, useful, and durable than ever before. And new technological advances have allowed measuring tools to become fast, easier, and more efficient. With the growth of the measuring tool market and increase in overall demand, these tools have also become more cost-effective. A large range of use cases for measuring tools means there can be a tool for every job. We envision a world in which every user has a measuring tool that fits their individualized needs on the jobsite – and we are certainly up for the challenge to get them there.

By Linda Tait, Business Unit Director, Measuring Tools at Bosch Power Tools

By Linda Tait, Business Unit Director, Measuring Tools at Bosch Power Tools

If there is one thing we humans have done almost universally over the past year, it is become more familiar with our living spaces. In that time, people’s attitudes have evolved, and the industry is taking note. The following are some key HVAC trends that highlight what topics are on consumers’ minds—and what manufacturers are Read more

If there is one thing we humans have done almost universally over the past year, it is become more familiar with our living spaces.

In that time, people’s attitudes have evolved, and the industry is taking note. The following are some key HVAC trends that highlight what topics are on consumers’ minds—and what manufacturers are paying attention to.

With Control Comes Power…Literally

Connectivity is one of the watchwords of our time and there are two areas of connectivity that are becoming more important than ever. One is on the consumer side, the other on the contractor side—they both provide greater user interaction and allow for more efficiency in time and energy.

Consumer Connectivity: consumers want more control with their living space. Virtually every day more online tools have become accessible to support this demand. Many manufacturers have recently launched apps to enable users to remotely control their thermostat and provide the diverse settings desired to create the ideal temperature. Early on, the intent was to let the consumer have total and instant control when it came to temperature—when they left their house for the day, they could shut off the heating or air and have it turn back on minutes before they return home. During Covid an interesting thing happened as people spent more time at home… their heating and air bills went up. Consumers quickly learned a key principle about energy efficiency, particularly in the summer or winter months. Instead of using extreme temperature settings, in an effort to be more efficient, they could actually manage their temperature and cost far better by keeping the temperature set at a constant rate. If they leave it at 72 degrees, it will fluctuate between 71 to 73 degrees. This takes less energy to cool the space within that parameter than it does to quickly lower the temperature from 90 to 72 degrees. Another significant efficiency lesson learned is an appliance such as a refrigerator cannot function optimally when the external room temperature reaches temperatures in the 80’s or 90’s. It takes a considerably higher amount of energy for proper heat exchange to keep those perishables cold and the ice cream frozen.

Consumers now want more nuanced control so they can optimize the temperature for specific times of the day and specific activities such as eating dinner, entertaining and sleeping. They have become enlightened to how much more advantageous it is to them to maintain not just temperature for comfort, but for electrical efficiency.

Contractor Connectivity: Today’s products are all manufactured with materials and technology that have improved performance, but parts still wear out, regular maintenance is needed, and repairs are still required. Enhanced connectivity gives new layers of precision to this process. For instance, if something quits or is functioning outside of recommended parameters within a smart HVAC system, it will trigger an automated response to the homeowner with a specific error code. When they call the contractor, the contractor can look up that error code on their app and see what it is specifically referring to. That way, if the compressor needs to be replaced, the contractor can check their inventory and make sure the exact compressor and associated parts are in the truck before they arrive at the customer’s home. This ensures that the service situation is resolved very efficiently. Customers feel taken care of and the contractor can quickly be on their way. Overall, both consumer and contractor are able to exercise far greater control over managing their needs.

Breakneck Speed of Innovation

The Internet of Things has been called the next industrial revolution—and for good reason. Having everything connected changes how we interact with our environment. The challenge is that change is coming much faster than many consumers are comfortable with. Since HVAC systems are all about comfort, manufacturers need to make sure their customers, who have long used an analog system are not intimidated with a complicated digital interface.

For example, a manufacturer brand found that older people who were used to a traditional thermostat were complaining about their experience with an upgraded system. They didn’t like the new touchscreen because there were no “real buttons” to push and too many options. The manufacturer went back to the drawing board and designed a new interface. Today their customers have two options, a slick, flat touch screen or an interface that is just as technologically advanced but includes some very user-friendly buttons that can actually be pushed. Following the trend of aligning the human factors and usability of the technology with the consumer’s level of comfort with the technology has paid off. The push-button option has become by far the most popular option with those over 55.

Everything Electric

In the wake of “heat domes” and hurricanes, the run from fossil fuels is happening faster than ever. The trend for electrification is as hot as the asphalt outside. In the Northeast, cities are placing a moratorium on gas where no new gas projects are allowed, and no new gas lines can be installed in cities for the heating of homes and buildings (only small gas lines for cooking).

One HVAC solution in particular is receiving a massive amount of attention these days. Heat pumps. There are many reasons for this, they are eco-friendly, require no fossil fuels such as heating oil or gas, like a boiler or furnace would use to make heat and they are very effective at both heating and cooling a space. On top of that, they use a small amount of electricity that in many cases can be offset with solar panels. Recent advancements in heat pump technology have overcome one of the greatest stumbling blocks to this option. They used to be limited in how far north products could be installed because of cold winters. Today, new systems can make heat in temperatures as low as -22 degrees Fahrenheit. Now energy-efficient heat pumps can be installed from Mexico to Northern Canada and everything in between.

Another hot item in the electrical area of heating and cooling is an exceptional alternative to traditional HVAC systems, ductless mini splits. These products focus on heating and cooling individual rooms by utilizing a combination of efficient technologies to achieve high SEER ratings while reducing electricity usage. These systems are used throughout Europe and elsewhere in the world and are now seeing a surge in the U.S. Part of the reason for the rapid adoption of mini splits is due to the military’s use of the technology in the middle east for the past 20 years. People saw how effective and efficient these solutions were in handling the extreme hot and cold temperatures found in the deserts and mountains of the Middle East. As they came back, they began to install them in their own homes.

Guest Blog by Melvin Harris

Guest Blog by Melvin Harris

Melvin Harris is a 22-year veteran in the HVAC industry. He serves as the Director of Residential Sales with Bosch Thermotechnology.

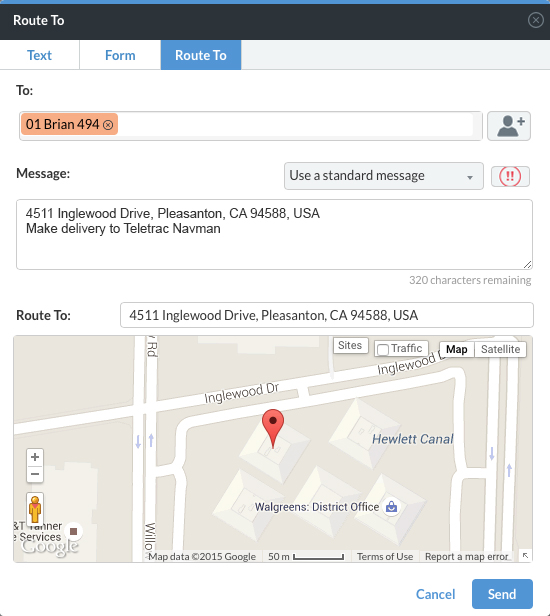

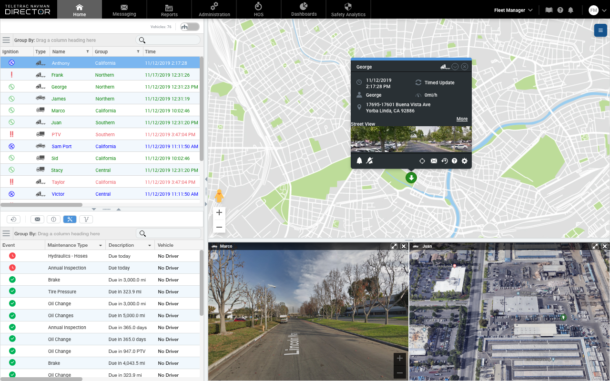

Wireless network technology is continuing to evolve, and members of the transportation industry who have come to rely on 3G networks for telematics in their connected vehicles have to consider how they’re going to keep up, lest they get left behind. Driven by ever-growing demands for more and faster data, major network providers are working Read more

Wireless network technology is continuing to evolve, and members of the transportation industry who have come to rely on 3G networks for telematics in their connected vehicles have to consider how they’re going to keep up, lest they get left behind.

Driven by ever-growing demands for more and faster data, major network providers are working ceaselessly on their respective rollouts of the fifth generation of mobile network capabilities, known as 5G, promising greatly reduced latency along with incredible speed and the ability to transmit large amounts of data in much reduced time. At the same time, the 3G networks are being phased out, with most networks set to go offline next year. Current 3G hardware is incompatible with the newer networks, and fleets that don’t upgrade in time will find themselves in the dark before long.

3G’s Clock is Ticking

Fortunately for fleet owners, there is still time to make the transition. Of the biggest providers, only AT&T is currently set to sunset 3G early next year – in February – with both Sprint and Verizon planning their shutdowns for December 2022.

Those dates come with a caveat, however: depending on the region, existing 3G infrastructure isn’t guaranteed to last until the sunset date, as regular maintenance may be dropped in favor of implementing hotly demanded 4G and 5G infrastructure instead.

Faced with uncertainty, fleet owners would be wise to get ahead of this technological leap. This is especially true for fleets that are using electronic logging devices (ELD). No fleets are more at risk of being negatively impacted by this change than those mandated to use ELDs. If these fleets fall offline, the systems will no longer be accurately tracking hours of service, and the drivers will be non-compliant, introducing a risk of those vehicles being pulled from service. To make this jump correctly, companies must carefully craft an internet of things (IoT) strategy that accounts for these newer, high-speed networks. Doing so will require implementation planning, cost analysis and training, giving all the more reason to act quickly.

The Benefits of Modern Hardware

Newer technology introduces greater functionality that will undoubtedly come in handy in the regular operation of a fleet. Even going from one step from 3G to 4G, the improvement will be immediately noticeable. Further futureproofing for 5G will ensure fleet owners stay at the forefront of technology for decades to come, all while enjoying the smoothest experience possible as the new networks roll out. The perks of being on a cutting-edge network are myriad, but highlights include:

- Faster speed and a wider network mean more reliable connections, particularly in areas where the wireless network is congested.

- Improved latency allows for sending a large mass of data such as alerts and events, including data-heavy content such as video.

- Communications between connected vehicles and the surrounding infrastructure is far more reliable and operate in close to real-time on high-speed connections providing instant information from the fleet and drivers.

- Massive amounts of data can be fed into AI-enabled telematics systems, turning real-time data into actionable safety, efficiency and compliance gains.

The key takeaway is that moving to new hardware isn’t a needless burden, but a net gain for a fleet’s drivers, customers and bottom line. Owners who get ahead now will avoid challenges down the line and reap the benefits above in the meantime.

The Road Ahead

Adopting 4G and 5G capable hardware is both an exciting opportunity and a growing requirement as older networks sunset, but the biggest reason for fleet owners to get started sooner is to make sure they have time to do it right. In the coming months, owners will want to take the following steps:

- Determine how many devices are still on the 3G network, and how many need to be migrated.

- Understand what kind of lifecycle to expect from new telematics equipment.

- Research modern telematics speed- and data-focused features made possible by new hardware, including AI and machine learning options, and consider how they can improve the fleet’s operation.

- Discuss the upgrade with the fleet’s telematics provider and learn about modern telematics and future facing solutions.

- Discover whether or not the telematics provider is charging their current customers for this type of upgrade, this can give you a glimpse into how they will handle related future tech refreshes.

- Ensure the new hardware is properly certified and has a pathway to helping companies with their regulatory requirements such as ELD or other regional specific programs

- Schedule the necessary vehicle downtime to make the upgrade with the minimum possible impact on downtime.

- Once everything is in place, implement a migration plan well ahead of your wireless network provider’s 3G sunset period.

These steps will take time, and fleet owners will want to feel confident in every step of the process. As such, waiting until the last minute to get started on the transition is ill-advised. Moving up from 3G isn’t as easy as flipping a switch. However, those owners who do put in the effort will avoid having to worry about their telematic systems potentially going out on them, crippling their essential dataflow for safety, compliance and business efficiency.

Now is the time to check with your telematics provider about the imminent 3G sunsetting or find a new vendor who can handle the inevitable upgrade.

Guest Blog By Andrew Rossington

Guest Blog By Andrew Rossington

Andrew Rossington joined Teletrac Navman in February 2016, working first as Vice President of Transtech (Division) before becoming Vice President, Transport Solutions in February 2018 then onto becoming Chief Product Officer in October 2020. In this role, Andrew is responsible for all transport industry solutions, including product development, go to market, team development and financial responsibilities. Since joining the business, he has overseen year-on-year growth in the transport vertical across the Australia/New Zealand region of Teletrac Navman. Prior to this, Andrew was the Chief Executive Officer for Transtech, which was acquired by Teletrac Navman. He has spent the last 20 years focused on transport industry solutions and has extensive experience managing software development teams and implementing key business systems for some of Australia’s largest transport operators and software companies, including Toll, ComTech and Dimensions Data. He is passionate about the transport industry and using technology to enable successful business outcomes.

Growing a business can often seem like it’s a stop-and-start process. You might see a little growth every year, but not as much as you would like. Is there a way to grow a construction business quickly? While it mightn’t be quick, there is a right way and wrong way to go about it, with Read more

Growing a business can often seem like it’s a stop-and-start process. You might see a little growth every year, but not as much as you would like. Is there a way to grow a construction business quickly?

While it mightn’t be quick, there is a right way and wrong way to go about it, with growth being steady over time. You’ll have to put in the effort, although that shouldn’t be too much of an issue.

As entrepreneur Dave Conklin attests, there are a few things every business owner should keep in mind, even those in construction.

Lead, Don’t Manage

Nobody likes a micromanager. Instead, employees want to be led, and that’s just as true for your contractors. If you’re a good leader, then you’ll inspire your team to do a good job. Part of doing this involves leading by example.

You’ll also need to provide constructive criticism alongside some positive reinforcement. These will make sure that your employees are happy and productive. In turn, that’ll lead to a better service for your clients.

Instead of managing your employees, you can then focus on other areas.

Be Selective With Your Projects

If you’re just starting a construction business, you might be tempted to take any project you can get your hands on. While the logic behind that is understandable, it mightn’t be the best approach.

Instead, you’ll need to look at whether or not these projects are profitable. Though you might be fine earning minimal profit at the beginning, there should still be a profit. If your workload is increasing, your profit should increase accordingly.

There’s also the fact that taking on unprofitable projects takes time away from those that could make you money.

Lean Into Your Strengths

Many construction companies try to be all-rounders. That’s led to the market being quite competitive. One way to stand out, however, is by playing to your strength and specializing in certain areas.

Though this could mean getting specific certifications, it will reap dividends in the long term. In time, you could become one of the more highly-rated companies in a specific area. That could include LEED certifications, among others.

Doing good work with each of these specialized projects will also increase your business further.

Make Sure To Network

Networking is one thing that many construction company owners forget about. However, it could be beneficial in a few notable ways. Alongside being a way to build brand awareness, you could find new vendors and other suppliers.

That could mean lower costs, with the savings going back into your company. Being active in your local community could also be beneficial, as this also helps to generate goodwill for your business.

Wrapping Up

If you’re growing a construction company, there’s quite a lot to keep in mind. Having the right contractors and employees, however, goes much farther than you might think. Though you’ll be overseeing them, they play a significant role in the quality that you deliver to clients.

Once you’ve that done, you’re free to concentrate on other parts of your business. A strong and steady approach can often be best, especially when it comes to building a company.