Mechanical Hub’s John Mesenbrink pent the day at UA’s annual Instructor Training Program in Ann Arbor, Mich. Tom Bigley, director of plumbing services, UA, was my gracious host. As a first time attendee, I was super impressed with the event, from the classrooms to the training truck labs to the apprenticeship contests. The video below Read more

Featured Articles

Mechanical Hub’s John Mesenbrink pent the day at UA’s annual Instructor Training Program in Ann Arbor, Mich. Tom Bigley, director of plumbing services, UA, was my gracious host. As a first time attendee, I was super impressed with the event, from the classrooms to the training truck labs to the apprenticeship contests.

The video below features Tom Bigley, UA director of plumbing, and Joe Fernandez Jr., UA training specialist, talk about the importance of the event and its training program.

Greetings everyone out there in Radio-land, and welcome to our show, Everything You Always Wanted to Know About Air-To-Water Heat Pumps* (*but were afraid to ask). Our hosts John Barba, Director, Sales Training NA, Taco, and Dave Holdorf, Product & Application Instructor – East, Taco, both of whom have a face for radio, are here Read more

Greetings everyone out there in Radio-land, and welcome to our show, Everything You Always Wanted to Know About Air-To-Water Heat Pumps* (*but were afraid to ask).

Our hosts John Barba, Director, Sales Training NA, Taco, and Dave Holdorf, Product & Application Instructor – East, Taco, both of whom have a face for radio, are here to take your questions and, if a miracle occurs, provide you with coherent answers.

And now, here are your hosts, direct via satellite from Cranston, Rhode Island – John and Dave!

John: Thank you everybody, and welcome to our show. I’m John and on the other microphone is Dave. Say hello, Dave.

Dave: Hello Dave.

John: Yep, those 11 semesters at the Connecticut School of Broadcasting are really paying off, aren’t they? Let’s get right to your calls and tackle some questions on Air to Water Heat Pumps. Dave, who’s our first caller?

Dave: First up JB, we have Elliot from Kansas City. Elliot, you’re up. What’s your question?

Caller: Hi, this is Elliot from Kansas City. Am I on?

John: Hi Elliot, you’re live, coast to coast. There are literally tens of people waiting on your question.

Caller: Wow. Tens, huh?

Dave: Okay, maybe dozens. So . . . what’s cookin’ Elliot?

Caller: Well, it’s pretty basic, but – how many BTU’s? What size house can I do with an air to water heat pump?

John: That’s a great question, Elliot. We get more calls about that than anything else. First, understand that any air-based heat pump extracts heat from the air using a refrigeration cycle. And it stands to reason that the colder it gets outside, the less heat there is in the air to, you know, extract.

Dave: That’s correct, JB. So as it gets colder out, the actual output of an air-to-air or an air-to-water heat pump goes down. So when you need more heat, the heat pump is actually producing less heat.

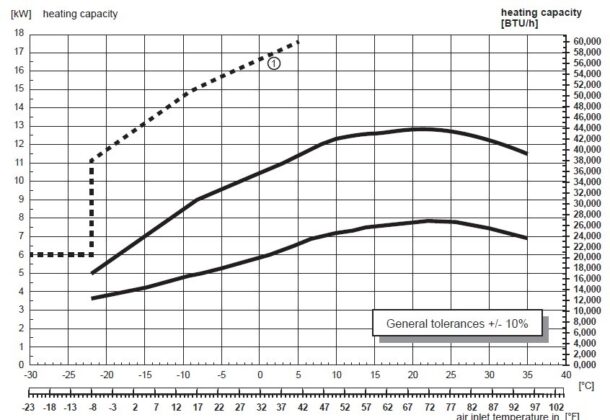

System M output chart:

Taco System M, air to water heat pump, heat pumps, heat pump technology, electrification, heating and cooling, plumbing HVAC

John: As you can see from this output chart for the Taco System M, as the outdoor temperature drops, so does the heat pump’s ability to produce BTUs for heating…

Dave: Uhhh, boss . . .

John: It drops off pretty sharply, as you can clearly see from this chart I’m showing you. When you hit 0o F, the output of the heat pump unit itself is about 21,000 BTUH . . .

Dave: Boss . . .

John: And when it hits its low limit of -7o F, its output is only around 17,000. It’s right there, plain as day.

Dave: Boss . . .

John: WHAT?!

Dave: It’s radio, they can’t see the chart.

John: Oh, right. Sorry. Anyway, that’s the case with any air-source heat pump. That’s why System M also includes a 6kW immersion heater in the buffer tank in its companion indoor unit, the HydroBox. That heater adds another 20,478 worth of potential output to the unit, for a total of just under 38,000 at -7o F.

And don’t fret about the immersion heater coming on willy-nilly. It’s intelligently controlled.

Dave: Willy-nilly?

John: It’s an industry term. Who’s our next caller?

Dave: We have Kyle on the line from the alliterative metropolis of Saskatoon, Saskatchewan.

Caller: Greetings, eh? It can get pretty frosty up here in Saskatoon. Can we hook up some backup heat for when it hits 40 below?

John: Gotta tell ya, my favorite Guess Who song ever is “Runnin’ Back to Saskatoon.” I love how it mentions all those great Saskatchewan towns, like Red Deer, Hanna and Medicine Hat.

John Barba

Caller: Uh, those towns’re in Alberta. Maybe I could talk to Dave instead?

Dave: I got ya, Kyle. It’s very easy to incorporate a backup or auxiliary heat source with an air-to-water heat pump. If the heat produced by the 37,000-plus BTUH System M at -7o F isn’t enough to heat the home, you can have the auxiliary heat come on at -8. Or, let’s say the heat pump/immersion heater combo comfortably heats a home at 10oF above with a total output of 46,000 BTUH, but it can’t take care of the load once it gets colder than 10oF. Then you can set up an auxiliary heat source – like a gas-fired mod-con – or, if the area isn’t allowing any new fossil fuel burning equipment, an electric boiler could meet that need. It’s actually a simple, single pole-double throw switch activated by outdoor temperature. It turns the heat pump off and turns the boiler on.

John: Great answer Dave. That’s exactly what I was going to say.

Dave: Yeah, but you were still runnin’ back to Saskatoon like the McKenzie Brothers. Let’s go to our next caller, Eric in Minnesota. Go ahead Eric:

Caller: (silence)

John: Eric, what’s your question?

Caller: (silence)

Dave: Welp, Eric’s not here. Let’s move on to Pete from Colorado. What’s up, Pete?

Caller: Hi guys. Long time listener, first time caller. Simple question: how does an air-to-water heat pump switch from heating to cooling?

John: Excellent question Pete. There are lots of ways to do it, ranging from a manual switch combined with turning a bunch of valves on and off, to a simpler, control-based solution.

Dave: That’s right, Boss. An integrated control, like the one with the Taco’s System M, uses an outdoor sensor. Based on the type of home, the climate and the level of insulation in the house, you can program an outdoor temperature at which the system goes into heating mode. Let’s say it’s 53 degrees. You can also program in the temperature at which the system goes into cooling mode. Let’s say that’s 63 degrees.

John: Remember gang, these are just examples. But Dave, if you go into heating mode at 53 oF and cooling mode at 63 oF, wouldn’t that leave a sizable dead band between the two?

Dave: Right you are, Sunshine. In that dead band, System M doesn’t do anything except maybe make domestic hot water if you need it to. If you need cooling and it’s 62 or 63 degrees, you can cool with the reserve of chilled water in the buffer tank. By the same token, if you need heating when it’s 54 or 55 degrees, you’ll have heated water in the buffer tank.

And if you have a houseful of people over for a spring holiday and you’re in the dead band, you can go into a forced cooling mode if you want to.

John: Awesomeness! We have two callers on the line now Dave, and both have the same question. Drake from Idaho and Tom from New Hampshire both want to know how an air-to-water heat pump can make domestic hot water when the heat pump itself is in cooling mode.

Caller: Yeah, this is Drake. I’m with that Tom guy. It doesn’t make sense that an air-to-water heat pump can make heated water for the indirect hot water tank and chilled water for cooling at the same time.

Caller: Yeah, this is Drake. I’m with that Tom guy. It doesn’t make sense that an air-to-water heat pump can make heated water for the indirect hot water tank and chilled water for cooling at the same time.

Dave: Great observations guys, and you’re correct. An air-to-water heat pump can’t make heated and chilled water at the same time.

Caller: Yeah, this is Tom. That Drake fellah is wicked smaht to ask that question. How can you make the watah hawtt when the freakin’ heat pump is making cold?

Dave: That’s where a buffer tank becomes really important. Let’s say the heat pump is in cooling made. With System M you’ll have a 30 gallon buffer tank filled with chilled water. When the indirect domestic water heater calls to make more hot water, the heat pump immediately jumps into heating mode.

Since you want to make hot water as quickly as you can, you can’t really wait for the 30 gallons of chilled water to be used up. And we don’t want the heat pump to turn all that chilled water into hot water. It would take forever and it’s not exactly what you’d call “green.”

John: Right you are, Dave. That’s where the piping in the System M indoor unit – what we lovingly refer to as the “HydroBox” – comes in. The piping arrangement in the HydroBox is called – are you ready? – a dual differential pressureless manifold. Its job is to hydraulically separate the heating and cooling piping circuits from the buffer tank-heat pump piping circuits. In addition, it also isolates the indirect DHW tank piping from both the heating and cooling circuits.

Dave: Exactamundo, my man. So when the indirect calls to make DHW, the heat pump itself goes right into heating mode, and the hot water from the heat pump bypasses the buffer tank altogether and goes direct to the indirect. The cooling circuit, meanwhile, can still run using the 30 gallons of chilled water that’s still in the buffer tank.

Caller: But won’t that water heat up quickly?

John: It’ll heat up over time, which means two things. First, the best applications for air-to-water heat pumps are very well insulated homes (think steroidal insulation) that don’t heat up or cool down quickly. That buys you time.

Dave: Additionally, you can program the unit to regenerate the hot water tank at specific times. Maybe the best time to do it during cooling season is at night when you’re asleep. You’ll be less likely to notice any temperature creep.

John: Wow, will you look at that. The old clock on the wall says time is up for this week’s edition of Everything You Always Wanted to Know About Heat Pumps* (*But Were Afraid to Ask). Thanks for being with us.

Dave: And if you enjoyed this show, make sure to join John and myself online during the spring and summer on Taco After Dark, our weekly nighttime program dedicated to all things hydronic, plumbing and heat pumps.

The fun starts once the sun goes down!

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource. As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover Read more

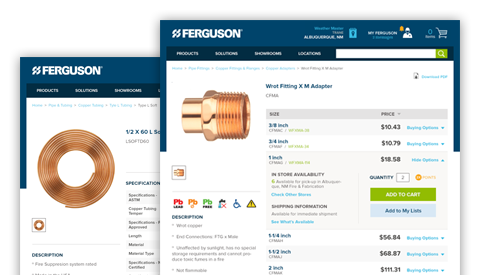

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource.

As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover, running a successful plumbing business requires access to quality products, reliable suppliers, and expert advice. In today’s digital age, having a robust online platform can significantly streamline your operations and contribute to your business’s growth.

In today’s post-COVID world, especially dealing with disruptive supply chain issues, it almost goes without saying; you can never have too much inventory on the truck or back at the shop. That’s why I rely on Ferguson.com, a comprehensive website that has plumbing contractor-specific resources available, all of which are literally just a click away. And that click provides real-time stock and pricing of more than 200,000 HVAC and plumbing products; I can see what’s in stock and my contract pricing.

My plumbing business relies on my wholesaler to carry a vast range of top-quality products from leading brands, and I trust Ferguson to provide those trusted, reliable, and durable solutions. Whether I’m looking for pipes, fittings, valves, fixtures, boiler parts or specialty items, I look to Ferguson.com.

Some really helpful features include “My Lists.” I am able to customize the order process with just a few clicks, instead of individually searching for the products I purchase regularly and organizing lists of the products I want. This ultimately has saved me time and has helped to streamline my ordering process. Ferguson.com even gives me the ability to share those lists I’ve created and keeps products I purchase under the “Bought Often” tab, which is automatically updated monthly.

The Quick Tools feature is a shortcut that makes it easy for trade professionals to quickly access other popular site features. It gives me the quick ability to order, reorder, find an order, or turn existing quotes into orders, all in one place. In some cases, I can even order online and have the order ready in an hour with Pro Pick-Up 1 Hour (at locations where Pro Pick-Up 1 Hour is available).

While traditional brick-and-mortar purchasing is still a viable wholesale solution, with Ferguson.com, I can gain access to a seamless and convenient online ordering system. This allows me to browse through products, check availability, compare prices, and place orders anytime, from anywhere. By simplifying the procurement process, Ferguson.com saves valuable time and effort, enabling me to focus on serving my customers better.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Sometimes I need to know what was on an order or the last time I bought a certain product. I’m able to find all of that online and end any confusion about my orders. If I need to see the status of an order, I can see it on my Ferguson Dashboard or Orders, and even get the proof of delivery. (Proof of delivery may not be available depending on how the order shipped or if it was signed for.)

Forward Thinking

Ferguson understands the importance of competitive pricing for plumbing contractors. By signing up for a Ferguson.com account, one can unlock access to exclusive contractor pricing on a wide range of products. This ensures that I can offer my customers competitive rates while maintaining healthy profit margins for my business. The savings one can achieve through Ferguson.com can significantly impact your bottom line and give you a competitive edge in the market.

It’s pretty simple, really. Creating an account on Ferguson.com provides plumbing contractors with a range of powerful tools to manage their business efficiently. By logging in, one can track his or her order history, access invoices, and manage one’s account settings, all in one centralized location. This streamlined account management feature eliminates the need for tedious paperwork and enables one to stay organized and in control.

What’s also cool about the site is that I can enroll for the free PRO Plus™ program. After I enrolled in this program, I now earn one point for every dollar I spent online. I can then redeem those points for cool prizes and earn Bonus Points faster by purchasing featured products. PRO Plus™ customers are also eligible for discounts with select businesses.

Ferguson.com boasts an extensive inventory of plumbing products, tools, and supplies, as well as expert advice and efficient account management, making it a one-stop solution for all of my business needs. By utilizing the features and capabilities of Ferguson.com, I can streamline my operations, relieve operational stress, and propel my business toward greater success. Sign up today and unlock a world of opportunities for your plumbing contracting business with Ferguson.com.

Setting the gun sight on a trophy elk in Colorado is a bucket list item, for sure. As an avid outdoorsman, Patrick Finley (@commercial_kitchen_chronicles) loves to fish, hunt and camp every chance he gets. “It is a goal of mine to get into shape and live in the wilderness and take a trophy bull,” says Finley Read more

Setting the gun sight on a trophy elk in Colorado is a bucket list item, for sure. As an avid outdoorsman, Patrick Finley (@commercial_kitchen_chronicles) loves to fish, hunt and camp every chance he gets. “It is a goal of mine to get into shape and live in the wilderness and take a trophy bull,” says Finley.

And when Finley’s mind comes back to reality for a bit, he talks about the fun he’s had cruising in his Jeep. “I always wanted a Harley, but the wife never approved. I would probably end up doing dumb stuff, let’s just be serious,” jokes Finley, who says he’s had a blast driving that Jeep and the Jeep community is full of all kinds of cool people. “I want to actually build it out and take it out to Moab, Utah.”

The Start

Finley started off as an electrician, wiring tract homes and got bored with it. Around the same time, Finley’s father worked for a company that got bought out by Ecolab, and he really wanted no part of working for a big corporation, “so he got me a job taking over his territory.”

Finley then took an opportunity to jump into the food service industry, working three years “hot” only, but wanted more. He left to make more money and to receive refrigeration training. “I jumped ship for a place that gave me money and promised training. I got the money but training was ‘parts are on the truck, figure it out.’”

Finley then took an opportunity to jump into the food service industry, working three years “hot” only, but wanted more. He left to make more money and to receive refrigeration training. “I jumped ship for a place that gave me money and promised training. I got the money but training was ‘parts are on the truck, figure it out.’”

Over time, Finley developed sleep apnea and says he was a nightmare to insure, and he bounced around to several places. “I was falling asleep on the job and wrecking vans.”

Finley got the apnea under control and ended up at General Parts, Indianapolis, where he has been for the past 12 years. He is currently a lead service tech installing and servicing commercial cooking equipment. “They took a chance on me and I promised myself I would do everything in my power to not make them regret it. I became the guy that would not say no, and it has paid off big time.”

The Challenges and Rewards

Finley says that the biggest challenge of the job is the diversity of all the different things out there. “Take combi ovens, it’s an oven in steamer in one. There are a hundred different manufacturers out there, and they all do things a little different. The aspect of never knowing what you are going to find wrong, and overcoming that challenge,” says Finley.

And the reward? It usually resonates with most contractors. “Nothing beats going into a restaurant that can’t open for business or is struggling without a piece of equipment—and you fix it. You are their hero. I know it sounds cliche, but you are. Nothing beats that feeling of knowing that their day just got a little better or easier because of you. A customer may be freaking out because their walk-in is down and you get it running for them. It is cool,” says Finley.

Finley’s advice for getting into the trades is fairly simple. “Take a chance. You never know where you may end up and what your true passion is. I had no idea I would be where I am at. I had a dream as a kid in vocational school. I was going to be a union electrician, and when I topped out, I was buying a new corvette. Here I am now, fixing commercial restaurant equipment and loving it.”

If you’re interested in the trades, says Finley, start off watching YouTube or Instagram videos of men and women out here doing things. Then if you think you would like it, reach out to companies and see if you can job shadow. “Don’t be scared to check out different ones. There are people starting over in their 40s and absolutely crushing it,” says Finley.

It’s important to start showcasing what we actually do, says Finley. “So many people do not even know this career exists. I talk to people every day and they say the same thing, they have no clue. If you want people to get interested, you have to put it out there.”

The Social Effect

When Finley reflects about social media, he admits he never thought he would be where he is without it. He says he followed a lot of the tradespeople on his personal account before he started up the account Commercial Kitchen Chronicles. “Honestly, it was born out of jealousy. I see all of these guys with huge followings, yet no one was showing off my little corner, the foodservice repair industry,” says Finley.

Initially, by Finley’s own admission, he was clueless. “I would just post random pictures or short clips, horribly edited and terrible captions. I met a few people and even someone fairly close that helped me a ton.”

Finley still doesn’t understand how, but he actually won Best Social Media Content at the 2023 HVAC Tactical Awards, which coincided with the AHR Show in Atlanta, where met so many cool people. “Huge accounts, and I was nervous. I sat down at the ’22 HVAC Tactical awards and I looked up to see Eric Aune and Andy Mickelson. I was literally freaking out. I am a huge fan of their show and there they were. We talked all night and had a blast. Next day at the show, same thing, meeting all kinds of really cool people that were just down to earth, hard-working, blue-collar people.”

Social media has really helped Finley step out of his shell. “I am not like this normally; I am usually quiet and reserved, and very shy. It has helped me find my passion, and it gives me a great platform to share my journey in the foodservice repair industry.”

The Commercial Kitchen Chronicles Podcast

According to Finley, the Commercial Kitchen Chronicles podcast was started on a whim, really. He made a comment about starting a podcast about the foodservice repair industry form a tech’s view. And actually, Finley had long forgot about it, until he ran into his boss and he had heard about Finley’s idea and they wanted to support it. “So, it was born—a little rough at first. No cohost, and I was clueless. I had the equipment and no skills.

“Now I have a few different guys that come on regularly and we all bring a different view to it. Dusty is fairly new to it. Jason came from the hospitality side of it before being a tech and understands both views on it. Rich is like me, full of passion and sometimes we may get ourselves into trouble, but we mean well.”

“Now I have a few different guys that come on regularly and we all bring a different view to it. Dusty is fairly new to it. Jason came from the hospitality side of it before being a tech and understands both views on it. Rich is like me, full of passion and sometimes we may get ourselves into trouble, but we mean well.”

They all share a common goal: doing the right thing for the customer because if you take care of your customer, everything else falls into place. “We talk about everything in a kitchen, from equipment, to people to service and more. We interview other techs to share their experiences, manufacturers, chefs, office staff. If you have a story to tell, we would love to hear it.”

The Balance

And how do you make time to take that elusive elk hunting trip to Colorado? “I have not always been the best at this, prioritizing my time. I struggled for money for the longest time. I have three kids and a wife to take care of so I became addicted to that OT.

“Then it seemed like my work relied on me so most of the of time I would miss things. My son got injured playing football. He broke both bones in his lower leg. He ended up laying on the field for 30 minutes, waiting on an ambulance and I wasn’t there. That was a huge turning point for me.”

Finley began to focus more on his family, but I didn’t cut back on work necessarily, but shifted to getting up earlier. “Most days I still can get 12 hours in. I get a few hours with the wife or kids and it seems to work out. I actually take my vacation time now as well. I have made a lot of memories the last five or so years, but I missed out on a lot and it sucks.”

So, if you’re out and about at any future trade shows, make sure you say hello to Pat. “I will be in Chicago for a regional meeting for CFESA in August but after that, the AHR Show in Chicago. Also, I usually attend the National Restaurant Association Show, which is also in Chicago, and it’s always a blast. All of the latest and greatest equipment is on display there and it gives me a chance to see what is coming up that I will be installing and servicing.”

In the Tool Bag

- Must haves: Veto bag and basic hand tools—majority are Klein with some Knipex.

- M12 surge and M12 flashlight, and all Milwaukee M18 and M12 power tools.

- I run a Fieldpiece SC680 for electrical diagnosis.

- Refrigeration tools: All Fieldpiece, vacuum pump, reclaim, job link probes, digital gauge set ups.

- I utilize a testo for flue gas analysis on combi ovens.

- I am a huge proponent of refrigeration pressing and love my RLS system set up.

- I am working on getting a press set up for water, drains and gas lines Hoping to end up buying a RIDGID RP 351. I do a lot of installs on combi ovens and they utilize 1.5- or 2-inch copper drains.

Artificial Intelligence (AI), digital twin, VR & AR, hydrogen fuel—all technologies pointing to the future of the plumbing industry. It’s really no wonder that the circulator industry—with the addition of Bluetooth-enabled technology and accompanying apps, for example, is moving into the 21st century as well. Couple that with US DOE mandates for efficiency, and you Read more

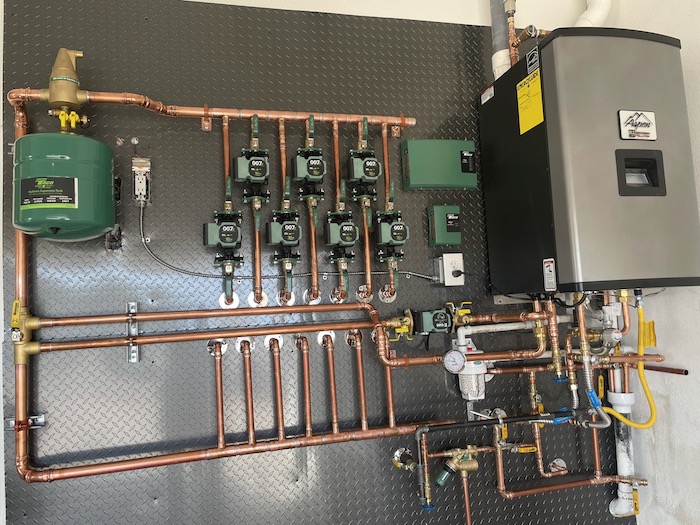

Artificial Intelligence (AI), digital twin, VR & AR, hydrogen fuel—all technologies pointing to the future of the plumbing industry. It’s really no wonder that the circulator industry—with the addition of Bluetooth-enabled technology and accompanying apps, for example, is moving into the 21st century as well. Couple that with US DOE mandates for efficiency, and you have the perfect storm of advancement. According to Taco’s John Barba, Director, Sales, Training, North America, the U.S. Department of Energy is tentatively setting mid-2025 as the date that mandated minimum circulator efficiency standards will be implemented. What that means on the specified date, manufacturers like Taco, Grundfos, Xylem, and others will no longer be able to manufacture and sell circulators that don’t meet a minimum efficiency standard.

“That doesn’t necessarily mean ECM technology, but as of right now Electronically Commutated Motor (ECM) is the only technology we have available that meets those standards; ECM is undoubtedly the direction our industry is going,” says Barba.

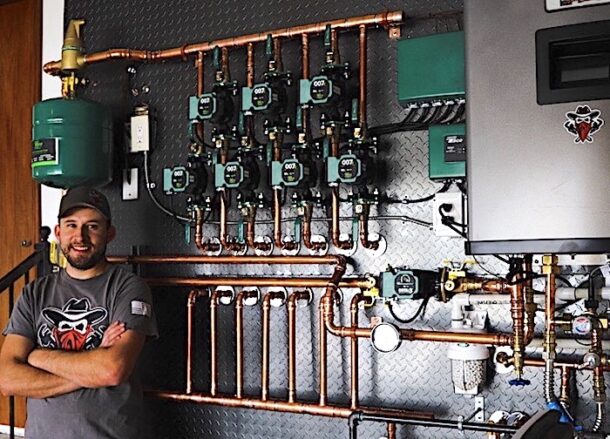

Keefer Rader, Outlaw Mechanical

According to Keefer Rader, owner, Outlaw Mechanical, Albuquerque, ECM will be the future as standard motor technology will no longer meet energy efficiency criteria. “I don’t know if Bluetooth technology will be the future, but it sure is nice to be able to monitor the equipment. I think Bluetooth and Wi-Fi technology will be a must for building management system (BMS) in our state.”

But by moving pumps and circulators into the “digital age,” some would ask, “why bother?” and “if it ain’t broke, why fix it?” “That’s an excellent question,” says Barba. “Part of me thinks back to something Henry Ford said a long, long time ago. ‘If you keep doing what you’ve been doing, you’ll keep getting what you’ve been getting.’ That’s the flipside to ‘If it ain’t broke, don’t fix it.’ The ‘if it ain’t broke’ idea is hard to argue with, but that doesn’t mean things can’t be made better, more efficient and more effective. After all, if good enough was truly good enough, we’d still be dealing with coal boilers and fireplaces. Those weren’t broke, either,” suggests Barba.

According to Barba, the fundamental truth is that building a hydronic system, putting pipe together so the water stays on the inside, connecting it to a boiler and having it make fire so people don’t freeze to death isn’t all that hard to do. A reasonably competent handyman could probably pull it off. But what makes a professional a professional is his or her ability to not only keep people from freezing to death, but to also create a system where the whole is greater than the sum of the parts; where the whole is designed to operate at peak efficiency and provide years of trouble-free operation. Variable-speed ECM circulators, when properly programmed and installed, are great tools to help achieve that goal.

“Of course, Henry Ford also said that he saw no advantage in new clocks” says Barba. “They run no faster than the ones made 100 years ago.” But again, it’s important to remember what we’re trying to accomplish. “Heck, cast iron boilers aren’t ‘broke,’ and they’re certainly less expensive, but modulating condensing boilers are more common now than ever before in residential hydronics. They’ve become ‘standard.’

“Of course, Henry Ford also said that he saw no advantage in new clocks” says Barba. “They run no faster than the ones made 100 years ago.” But again, it’s important to remember what we’re trying to accomplish. “Heck, cast iron boilers aren’t ‘broke,’ and they’re certainly less expensive, but modulating condensing boilers are more common now than ever before in residential hydronics. They’ve become ‘standard.’

“However, it makes zero sense to install a high-efficiency modulating condensing boiler and then not installing the outdoor sensor or enabling the outdoor reset. Even if the boiler has to run up to 180 degrees for fin-tube baseboard, it can still modulate and reset the water temperature as it gets warmer outside. Not doing so is basically wasting your customer’s money. “

By the same token, says Barba, all of the components you install with that modulating-condensing boiler—or even a cast-iron boiler, for that matter—should be purpose-chosen, meaning they are specifically selected in order to enhance the overall performance of the system—to make the whole greater than the sum of the parts.

“One thing variable speed technology has taught the industry is that the circulator plays a bigger role in overall system efficiency than we’ve ever given it credit for,” says Barba. “Sure, the boiler makes the heat, and sure, the heat emitters deliver the heat. But it’s the circulator that facilitates the journey. If we are overpumping, and even with ECM technology, we’re almost always overpumping, we’re limiting the overall performance and efficiency of the system, not enhancing it. A typical three-speed, standard efficiency circulator is almost always set to high speed or, as we like to call it, ‘contractor no-callback mode.’

“On the one hand, unless there’s velocity noise, there’s no immediate downside to doing so. However, pumping 5 gallons per minute through a zone that only needs 2 gallons per minute under design conditions means you’re pumping at a rate 2.5 times more than is required. In a perfect world, you’d have a 20-degree Delta-T under design conditions, but in this example, the best Delta-T you’ll ever see in that system is 8 degrees. That would mean with a mod-con boiler sending out 140-degree water on the coldest day of the year, the return water temperature would be about 132. We’re not condensing nearly as much as we could be, and we’re leaving an awful lot of efficiency on the table, but no one will complain about being cold.”

“Cavemen! I don’t understand why people are afraid of new things,” shouts Rader. “I’m a big proponent because I know Taco tests everything stringently so I know when it comes out of the box, I’m not likely to have an issue with it. I love having four circulators on my truck that I can typically adapt to any system and make it more efficient and work better. The double 0015e, 0018e, vt2218—this is my favorite, because people can see data in front of their face and understand the value—and 0026e.”

But Bluetooth?

As for Bluetooth technology and its associated app, it’s simply a way for an installer to make sure the ECM circulator he or she is using is, in fact, doing what he or she wants it to do. The myths and misinformation about ECM and variable speed technology that are common in our industry are astounding, says Barba. No, they do not size themselves and no, they do not always give you the right flow. What ECM and variable speed technology allows us to do is properly program a circulator so that it performs as close to what a system requires as possible. These things aren’t magic and they don’t “do the thinking for you,” or “take the thinking out of it.”

“You can’t just slap one of these things in, push a button and let it do the rest,” says Barba. “This isn’t the Hogwarts School of Hydronic Magic. ECM circulators don’t think and they aren’t magic. But what they are is obedient. They will do what you tell them to do – and the benefit of Bluetooth technology is it allows the installer to make sure a circulator—in Taco’s case the 0018e Delta-P technology circulator—operates as close to the actual system requirements as possible.”

Additionally, residential hydronics has a chronic overpumping problem, continues Barba. Pick any residential hydronic system and chances are it’s WAY overpumped. Overpumping is one of those insidious problems—no one will ever complain about being cold, but over pumping means more GPM is being pumped through a zone or a system than it needs. When that happens, the system Delta-T is small and gets smaller as the outdoor temperature increases.

This isn’t supposed to happen and it’s not needed to make a system work, although you’ll hear people mistakenly make that claim. What a shrinking Delta-T does do is it sends warmer and warmer water back to the boiler. We don’t want that to happen at all with a modulating-condensing boiler, and we really don’t want it to happen with a cast iron boiler, either (as long as we’re above the condensing point). When that return water temperature is higher than necessary, boilers tend to short cycle and, in the case of a mod-con, it won’t “con” as much as it could. It’s almost impossible to quantify mathematically, but it’s reasonable and logical to presume that overall system efficiency (and fuel consumption) will suffer.

“And short-cycling doesn’t do any of the moving parts in a system any favors. It won’t take long for any key—and expensive—component in a mod-con boiler to fail prematurely. At that point, someone is left with some ’splaining to do,” says Barba.

Bluetooth technology has to be useful and hold value to the contractor, and that we’ll see about, says Barba. “What we’ve found in the five years we’ve had Bluetooth technology in the market is there are contractors who get the value right away, and others who question the value. That’s to be expected. When we show all of the capabilities of the circulator, show them how easy it is to set up the circulator to optimize system performance and—most importantly— what that optimization is important, we see more who see the value and fewer who question it,” says Barba.

“That said, we do see contractors who roll their eyes at the word ‘app’ and don’t want anything to do with it, and that’s fine. We have the VR 1816, which we’ve had since 2014, the 007e, which we’ve had since 2015, the 0015e3—which we’ve had since 2017 and the VT-2218, a Delta-T variable speed circulator that we’ve had since 2011. Different strokes, meet different folks.”

“I’ll tell you what I wish they put a small screen on the 0018. I really love this circulator because I can get real time data on my iPad and set a circulator to pretty much exactly what that zone needs,” says Rader. “I prefer to use them on zone pump systems. I also like to use them on the head scratcher systems so I can try to compile as much data as possible. A lot of times it becomes more of a tool than product.”

And beyond initial setup? “Initial setup isn’t just a throw-away item; it’s the most important element of using, and maximizing, variable speed circulators. And Bluetooth connectivity gives you stark visuals and really numbers of what it is you’re doing. As my co-trainer Dave Holdorf says, Bluetooth for the first time lets you see what’s actually happening inside the pipe. It’s real and it’s now knowable and quantifiable,” says Barba.

Added Costs?

Let’s face it, with new technology inevitably there’s going to be added costs. “There are added costs, but I have found when selling a new circulator—when I explain to the customer, the benefits of a properly sized circulator—that their buyback should be within a year. For instance, if I have a circulator that speeding up and slowing down based upon how many zones are opened or closed at that time, we are not wasting fuel. We are directing the heat at the proper speed to hit maximum efficiency,” says Rader.

People do ask all the time, “How do it sell this to my customer?” says Barba. There are two answers to that. The short one is if it’s a simple swap out—a new circulator for a dead one—it can simply be a matter of explaining these new circulators are much more electrically efficient than the standard models, use about half the electric and can make the system work better and more efficiently for the long haul. Often, that’s enough of an explanation.

If someone wants particular, the Hydraulics Institute has created labeling for ECM circulators that all of the major manufacturers have adopted, indicating relative efficiency ratings (the higher the number, the more efficient the circulator—although once you reach a certain point, the practical differences are minimal). By using a formula provided by the Hydraulics Institute, one can show how quickly the more efficient circulator will offset the higher purchase price— it’s usually within two, maybe three heating seasons.

If it’s a full boiler change out, the difference in price between a standard circulator or circulators compared to ECM circulators—in the overall picture of the job—isn’t huge and gives the contractor talking points as to why he or she has chosen specific circulators, and why it’s best for the system to do the job right. “I’ve had customers tell me that their customers aren’t asking for ECM technology, so there’s no market for them and besides, they’re too expensive. I’ll go with another Henry Ford quote: ‘If I’d asked people what they wanted, they’d have said ‘faster horses,’” says Barba.

Depending on where you live and work, Barba says, ECM circulators may actually be less expensive than standard efficiency circulators. Many states offer instant, at-the-counter rebates from utility companies to incentivize ECM adoption. It makes sense—if wider adoption of lower-wattage circulators takes place, that’s less of a load on the power grid. The utilities are simply buying efficiency—it’s no different than with light bulbs or other low-consumption appliances.

In non-rebate states, the comparative purchase cost is higher—anywhere from a little bit to a lot, depending on what you want for a particular job. We’ve had great success with the 007e and 0015e3—both variable speed Delta-P ECM circulators—that only have the features and operating parameters that people might need for a particular job. If you like 007s and want similar performance in an ECM circulator, the 007e is virtually identical in performance. The 0015e3 is a seamless transition from your typical 3-speed circulator and works great with zone valves or as a zone pump. The multi-feature, multi-function circulators offer more features, but that comes at a higher purchase price.

Ultimately, ECM, variable speed and Bluetooth technology isn’t a matter of making the water go round-and-round the pipes better, says Barba. It’s simply a matter of using the latest technology to make sure a key part of the system is doing its job to ensure that system is working as efficiently and effectively as possible, ensuring the system itself remains as trouble-free as possible for as long as possible, and that the customer is getting the most out of what they’re paying for. “We’re all consumers in one way or another, and none of us want to pay top dollar and then get only 80 percent of what we’re paying for.”