Yes! (If the boiler does it for you) Of all the commodities available to us, time is the most precious. As humans have done for eons, we all trade in the commodity of time. Successful contractors regularly step back to assess whether they are getting the most out of the hours they’ve bartered. This is Read more

Featured Articles

Yes! (If the boiler does it for you)

Of all the commodities available to us, time is the most precious. As humans have done for eons, we all trade in the commodity of time. Successful contractors regularly step back to assess whether they are getting the most out of the hours they’ve bartered.

This is where the team at U.S. Boiler Company was determined to add value with the high efficiency Alta boiler. Innovation at U.S. Boiler goes beyond durability and performance to saving your most precious resource: a skilled tradesperson’s time.

Gas analyzers should always make their way to the jobsite.

What are the most time-consuming and painful steps of installing or servicing a boiler? The Alta boiler addresses several steps near the top of your list, but it doesn’t just make them easier. You can skip them. Let’s start with combustion setup.

First, we can all agree that combustion setup takes time, and that improper setup can lead to big problems. What are the biggest challenges with combustion set up?

Ambient Temperature

If you have a passion for all things measured in horsepower, you know that your car, boat, motorcycle, etc. runs best on cool fall nights. This is because the cooler air is denser. That is, it contains more oxygen per cubic foot. The more oxygen in the cylinder, the more power generated.

Contractor conducts setup of the Alta boiler by U.S. Boiler using the USB-Connect phone app.

With boilers, we face a similar dynamic. Most of us perform preventative maintenance during the summer months. At this time of year, air temps can range from 50°F to 100°F or more, depending on your location.

Once winter rolls around and the outdoor temps drop, those combustion targets we worked so hard to achieve go right out the window. The dense air will skew your combustion to the leaner side of the spectrum (not enough fuel for the oxygen present) because your calibration was conducted when the ambient temperature was higher.

The problem gets worse if the combustion check was skipped altogether. If the boiler is already too lean, you might be required to pay a free visit to the site during the colder months and encounter the homeowner sporting what is colloquially known in the industry as “lemon face” due to a no heat call.

Well … It’s Complicated

Technicians face the daunting task of working on a wide variety of equipment and trying to keep pace with industry advancements. When setting the combustion on most high efficiency boilers, proper setup requires tuning at both high and low fire. This means knowing which screw to adjust, how to lock the boiler in high and low fire, and hoping the system has enough capacity to dissipate the heat generated during testing to keep the boiler running. That’s a lot to expect of a seasoned tech, much less some of the newer faces joining our industry.

What Analyzer?

Like fishing, combustion testing is frequently accompanied by “far away eyes and bold-faced lies.” I’m constantly amazed by the number of technicians who share the following comments with such a level of innocence, sincerity and/or ignorance that I’m not always sure how to respond.

- “We don’t have an analyzer. Never have! Boss says we don’t need one.”

- “We don’t have an analyzer. Boss keeps it in the office…”

- “We have an analyzer, but the last time it was calibrated was during the Nixon administration…”

- “We have an analyzer, but it doesn’t work. Ever since we left it in the truck last winter the numbers are all wonky.”

- “We have an analyzer, but I’m not trained on it.”

These are just a small sample of the excuses I’ve heard. There are many, many more, some of which deserve an A+ for creativity. Long story short, there’s cause for concern on whether the boiler was set up correctly, if at all. Which brings us to the Alta.

Alta Does It for You

The gas train in the Alta boiler utilizes an adaptive combustion system. Unlike a simple pneumatic gas train, gas adaptive technology uses the flame signal to constantly tune combustion. What does this mean to homeowners, contractors, and technicians?

Everyone is familiar with the K.I.S.S. concept. We use it in a slightly different manner for the Alta. Keep It Sweet and Simple!

Sweet—Alta’s adaptive system constantly tunes burner combustion, keeping the boiler consistently in the sweet spot, maintaining the cleanest heat exchanger possible while achieving optimal efficiency.

Simple—Because the Alta adaptive combustion system uses basic components and a time-tested method of monitoring, the Alta solution is elegant and ingenious, without being complex. No more worries about changing combustion air temperatures or watching over techs as they adjust combustion.

Alta does the heavy lifting for you by tuning itself to site conditions. The boiler runs its own combustion setup, so you don’t have to.

Technology should not replace knowledge of hydronic systems, but it should make your life easier. You should own and be competent in the use of a combustion analyzer so you can be sure there are no installer-induced failures like reversed low profile termination fittings (it’s happened) or wads of insulation that inadvertently get lodged in the combustion air piping (yep, this happened too!), or cross contamination at the vent termination (the list goes on).

Adaptive combustion delivers faster installations and fewer callbacks on combustion issues. That’s how you do more with the time you have. So go ahead, skip combustion setup with Alta.

Tom Secondino is a Technical Sales Support Specialist for U.S. Boiler Company, a manufacturer of residential and commercial heating products, including condensing, non-condensing and electric boilers. For more information on the Alta boiler, visit our Alta Product Page

Jimmy Anderson has been a boiler technician in Burnley, Lancashire, UK for 26 years. His story is unique. While he’s made appearances in the United States on social media, to my knowledge, his story has never been told among the skilled trade community in North America. I believe it’s worth telling, especially now, during the Read more

Jimmy Anderson has been a boiler technician in Burnley, Lancashire, UK for 26 years. His story is unique. While he’s made appearances in the United States on social media, to my knowledge, his story has never been told among the skilled trade community in North America. I believe it’s worth telling, especially now, during the holiday season, while we’re reflecting, spending time with loved ones, and enjoying the warmth that our heating systems provide. – Dan Vastyan

A promise made

It was 2013. William Edgar James Ward Anderson, only 16 weeks old, lie in a hospital bed dying. Bedside on his knees was his father, Jimmy, who made a promise to his infant son: William, if you pull through this, I will become the man I should be.

William passed away shortly thereafter, leaving a gaping void in his father’s heart.

William Edgar James Ward Anderson in the hospital in 2013, shortly before passing away.

“I became very angry with the world and couldn’t accept that I’d lost my son,” said Jimmy. “I carried that anger with me. It ate me up and led to misery and a chain of poor decisions.”

Jimmy drifted through life, working, existing in pain, and quietly raging against his loss. This continued for four years. Then a service call changed everything.

A scene from the past

In 2017, Jimmy was called to a property to look at a malfunctioning boiler system. When he knocked on the door, he heard someone faintly shout for him to come in.

In the back room, Jimmy found an old man lying in bed. It was obvious from his condition and the hoist next to the bed that the man was very ill.

“The sight immediately took me back to the day I said goodbye to William, the day I made the promise,” said Jimmy. “The room reminded me so much of the hospital, and the man looked like a bigger version of my son when he died. I thought, ‘Wow, is this William’s way of telling me to follow through on my 2013 promise? I took it as that.”

Jimmy holds a Chimella, a device used to block chimney drafts.

Jimmy learned that the man needed a second opinion on his boiler system. Another company had visited previously and told him that the system needed to be replaced at a cost of £5,500. While inspecting the boiler, Jimmy found that the unit had been deliberately tampered with.

It became obvious that the first technician (or “engineer,” as the British call techs) to visit the house was trying to rip off the old man. Jimmy contacted the company about the scam and they denied it, so he gave them an ultimatum: “fix it or I’ll prove you’re running a scam.”

It turned out the technician had been acting on his own and was fired immediately. The company made good on the mistake by installing a new boiler and gave the old man an additional £1,000.

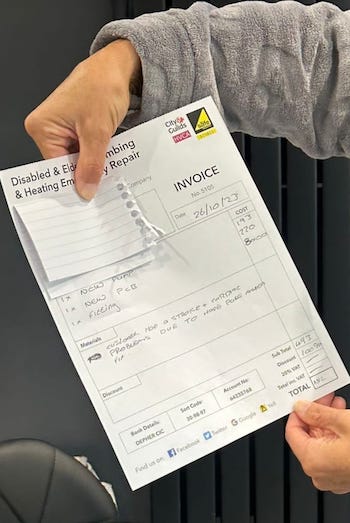

In March of 2017, just two weeks after that incident, Jimmy founded Disabled & Elderly Plumbing and Heating Emergency Repairs (DEPHER).

Almost any need

DEPHER began small, with Jimmy conducting charity plumbing and heating work whenever he identified a need. In short order, the need among his local community outpaced his ability to respond.

Part of the DEPHER crew with Simon Wild, inventor of the Chimella, who came to support DEPHER.

Today, the company employs 13 technicians in the Burnley area, and subcontracts charity work to a network of other involved companies. In all, there are roughly 530 technicians across the country who answer the call.

DEPHER also conducts for-profit work, which, along with donations, is used to fund the charity work. For example, actor Hugh Grant has donated £55,000. As time went by, DEPHER expanded its impact beyond plumbing and heating.

DEPHER customers hold a new thermostat after being given a new boiler.

“We have several community support initiatives for people genuinely in need,” said Jimmy, who is a father of six and grandfather of four. “We provide food to low-income individuals, at times we cover gas and power bills, we provide terminal illness support, offset funeral expenses and we provided COVID support during the pandemic.”

So how do potential recipients of this support – whether directly related to a plumbing or heating issue or not – qualify for DEPHER aid?

Anyone over 65, anyone who is considered vulnerable, terminally ill, or handicapped, receives free or deeply discounted boiler or plumbing work. Anyone struggling with low income can receive free food deliveries. Anyone who loses a family member and cannot afford the final expenses will be given £500 to offset funeral costs.

To date, DEPHER has helped 52,000 families; Jimmy is now known as “Britain’s kindest plumber.”

Of course, all the people that DEPHER helps are very grateful, but there are a few detractors.

“A few people, specifically among other plumbing and heating companies, don’t care for me,” said Jimmy. “They think that the charity work we do takes money out of their wallets.

A heating repair invoice from DEPHER with a 100% discount.

“The simple fact is that the people we’re helping can’t afford professional services,” he added. “But I don’t need fans. This is what we do, and we’re not going to stop. If you like it great, if you don’t, that’s fine too.”

“If you aren’t doing God’s work, the devil wouldn’t be pointing his finger at you,” said Jimmy regarding the nay-sayers. “I get all the validation I need from seeing the impact we’ve made. Each situation is unique, whether DEPHER is providing food or fixing boilers. They all stand out, but occasionally, one really leaves a mark.”

Jimmy can recall an 84-year-old woman who’d hung a noose from her rafters because she could no longer afford to live and was ready to end the suffering. DEPHER got her the financial and psychological help she needed, and she’s still alive today.

Headwinds

While the US housing market, energy costs and food expenses have squeezed American budgets, Great Britain has had it worse. Food and energy costs across Europe have been higher than in the US for decades, but the energy crisis resulting from the war in Ukraine has pushed current living costs to new heights. The English have given this a name: the Cost-of-Living Crisis.

DEPHER has 13 technicians serving the Burnley, Lancashire, UK region, while subcontracting charity plumbing and heating work to a nationwide extended network of 500+ technicians.

“The Cost-of-Living Crisis has impacted DEPHER in two ways,” explained Jimmy. “There’s more need for community support than ever before, and even those who’ve made donations in the past are feeling the crunch. So, there’s less donation money coming in.”

Unlike most charitable organizations, DEPHER can at least partially self-fund its giving through the for-profit work they do. About 30 percent of their work is hydronic, and the rest is plumbing.

If you’d like to learn more about DEPHER, you can find them on Instagram (@dephercic2021 and @depher_cic), X, formerly Twitter (@depherUK), Facebook (Depher CIC) and TikTok (@dephercicuk1066).

The Pennsylvania Petroleum Association (PPA) has become a leading source of knowledge and training expertise for HVAC professionals throughout the Northeast and Mid-Atlantic regions. One of their most popular courses, Advanced Hydronics, is offered as a one-day course at PPATEC—the association’s Technical Education Center in Middletown, Pa.—one to three times yearly, and as a half-day Read more

The Pennsylvania Petroleum Association (PPA) has become a leading source of knowledge and training expertise for HVAC professionals throughout the Northeast and Mid-Atlantic regions.

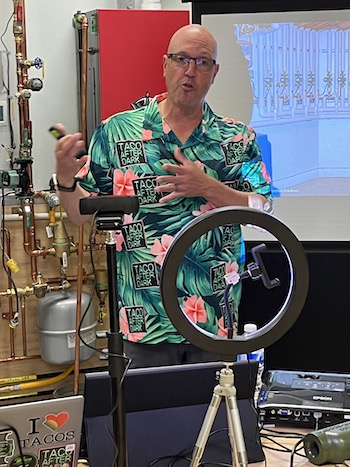

One of their most popular courses, Advanced Hydronics, is offered as a one-day course at PPATEC—the association’s Technical Education Center in Middletown, Pa.—one to three times yearly, and as a half-day session 4 to 6 times yearly by instructor/trainer Dave Holdorf. In October ’23, he returned to PPATEC (his 5th visit in ’23) to lead their advanced hydronics course. Holdorf not only wrote the book used for the multi-day course, but also designed the laboratory they’re used for hands-on training.

Dave Holdorf giving his in-person Adnvaced Hydronics course at PPATEC.

Holdorf’s become a cult phenomenon and is now regarded as one of the nation’s best trainers of hydronic trade professionals.

His book, Advanced Hydronics, published by NORA (National Oilheat Research Alliance), is a favorite resource among hydronic system technicians.

An outgoing and amusing educator, Holdorf is also a Taco Comfort Solutions’ Product and Applications Instructor—East, a role that routinely puts him in the “bullpen” with two other equally-engaging and amusing hydronic experts, John Barba and Rick Mayo. Their “Taco After Dark” (see sidebar) webinar was hosted by PPATEC on October 4, with Holdorf as the emcee.

Holdorf has been in the hydronic industry for 25 years, specifically in the radiant heating side of the business for the better part of his career. Holdorf was presented with the “Dan Holohan Instructor of the Year” award in 2020.

“I love what I do—and the best of it happens when I’m among an group of trade professionals. We laugh, swap stories and learn. What could be better?” asked Holdorf.

‘Mecca’ for Hydronics Training

During his trips to PPATEC’s growing facility, Holdorf enjoys the training spotlight typically focused on PPA’s other HVAC instructors, including their very own Lead Technical Trainer, Alan Mercurio—one of the most popular trainers in the Northeast region.

Alan Mercurio (c), doing what he loves to do — teach.

Trade pros flock to the facility near Harrisburg as something of a “Mecca” for HVAC technicians eager to deepen their understanding of installation and service techniques and theory. Visiting trainers at the PPATEC facility, many of whom make multiple trips each year to the facility, include Brian Kiernan of Energy Kinetics, Bruce Graham of Carlin/Hydrolevel, Curtis Martin or R. W. Beckett, Joe Sacco of Riello, and Ron Beck, Training Manager emeritus, U.S. Boiler.

Advanced Hydronics

In October, Holdorf spent several days teaching advanced hydronics, much of it from his book, to jam-packed trade pro audiences at PPATEC. There wasn’t a spare seat in the classroom.

“We love it when Dave comes to teach. He’s one of our most popular trainers,” said Mercurio. “He has a special way of keeping a classroom full of technicians engaged and eager to learn.”

Contractors arrive at PPATEC for in-person training.

According to Holdorf, anyone can put together a bunch of parts and call it a hydronic heating system. But are those parts and pieces selected properly and being used as they were intended? That was the focus of the advanced hydronics course, intended to take attendees through the decision process, prior to system design. The goal: to guide deliberate, informed system development, startup and commissioning.

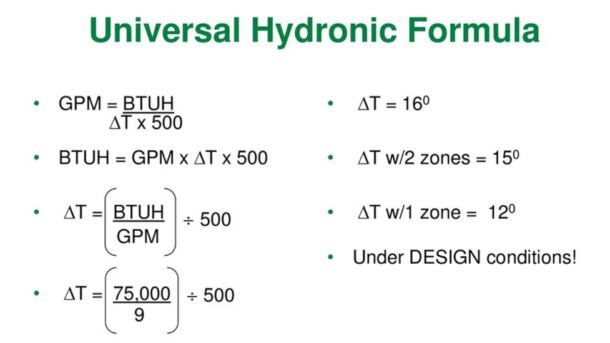

Of course—you’ve heard it many times before from these savvy hydronic-ians: every good system begins with a heat load calculation. “The math isn’t difficult, but it’s necessary,” assured Holdorf. Whether in class, or speaking to a Taco After Dark audience, Holdorf and Barba steer participants toward the Universal Hydronic Formula.

In essence:

• GPM (gallons per minute, or required flow) = BTUH ÷ ∆T and multiplied by 500

• ∆T is the temp drop across the piping circuits (difference between supply + return)

• Why the 500?

“Well, it’s a math shortcut,” he explains. The number stems from the weight of one gallon of water (8.33 lbs.) x the number of minutes in an hour x 1, or . . .

8.33 x 60×1 = 499.8 . . . and 500 is close enough.

To provide comfort within a home, a well-designed and installed hydronic system provides proper thermal energy transfer (or the ability “to carry the BTUs”) to all points of distribution. For residential systems, Holdorf recommends at 20°∆T.

From there, Holdorf and Barba led the live and online audience through several explanations that tie to this formula:

• Glycol is thicker and doesn’t carry as much energy (and its pH should be checked routinely)

• Proper flow rate for a load calculated at 82,401 BTUs (a decent-sized home):

GPM = BTUH ÷ (∆T x 500), so . . .

GPM = 82,401 BTUs ÷ (20 x 500)

GPM = 8.2

From there, Holdorf leads his audience through the basics of transporting that heat outward for distribution, and back to the boiler to be reheated:

• ¾” copper will move 2-4 GPM

• 1” pipe will move 4-9 GPM – the right size for the 8.2 GPM calculation above; typically, this is all that residential systems require. Large pipe is required for “starter castle” homes and commercial purposes.

• 1-1/4” pipe allows movement of 8-14 GPM

• 1-1/2” permits 14-22 GPM

Too much flow creates velocity noise. Insufficient flow makes it difficult to purge entrained air from the water. The challenge of air within the hydronic solution—whether water, or glycol—became the segue to air elimination. And, with Holdorf and Barba guiding the conversation, it becomes a fascinating topic: one you can easily find on the Taco After Dark website: https://www.tacocomfort.com/training/online-training/taco-after-dark/ (take your cursor to the Oct. 4 broadcast).

Heat Emitters; and Pipe Sizing, Air Control and Pumping Away

Once you know the BTUH heating load, you can now get down to the business of adequately sizing heat emitters. Typically, the choices are: fin-tube baseboard, cast-iron and panel-type radiators, radiant floor heating +/or hydro-air.

From there, Holdorf and Barba discussed the use of cast iron and mod-con boilers, and air-to-water heat pumps. They also illustrated how to interpret output and design charts so installers can match heat emitters to the water temperatures produced by the heat plant

Holdorf and Barba also spoke about how to properly size a boiler header and distribution piping based on the BTUH load.

A few other points stirred lively conversation among participants:

- Hydronic system components, what goes where and why

- Boiler size

- Pipe size

- Near boiler piping—best practices and options

- Finally: controls

“I’ve now learned from Dave [Holdorf] on a couple of occasions at PPATEC,” said Eric Love, a technician with HB Home Services, a division of H. B. McClure Company, based in Harrisburg. “He’s a terrific instructor, and very entertaining. He’s one of many reasons I now look forward to more training there.”

Free Online Training for Boiler Heating Systems

Taco After Dark – LIVE from PPATEC, 10-4-23, on Mechanical-Hub

Weekly, Wednesday evening Taco After Dark webinars have risen to the top as the nation’s most popular online source of live (and YouTube-archived) hydronics knowledge and expertise.

The focus of Taco After Dark—practical, real-world solutions to the challenges hydronics professionals face every day.

Mechanical-Hub

The, um, “Magical Mystery Tour” of Taco After Dark began early in the Covid pandemic. Holdorf and fellow Taco trainers John Barba and Rick Mayo made a call to Mechanical-Hub’s managing partners – hoping to offer an exciting online training platform. Long story short: Taco and th’ Hub worked together to engaged both of their trade pro audiences. These days, all of the Taco After Dark broadcasts are recorded onto Mechanical-Hub’s YouTube page.

As th’ Hub’s Editor, John Mesenbrink, so succinctly said, “Online learning brings us together.” And that’s exactly what happened when Holdorf went live with the “Taco After Dark” broadcast from 7-9 pm on October 4 from PPATEC’s newest hydronic lab.

As th’ Hub’s Editor, John Mesenbrink, so succinctly said, “Online learning brings us together.” And that’s exactly what happened when Holdorf went live with the “Taco After Dark” broadcast from 7-9 pm on October 4 from PPATEC’s newest hydronic lab.

Before the online audience joined in to learn, and to contribute, Holdorf enjoyed connecting with show co-host John Barba—Taco’s lead residential instructor —and special guest Dave Yates who was the owner (now retired) of York, PA-based F. W. Behler, Inc., a full-service mechanical contracting firm. Talk about a forum for fun! These guys could make you laugh through the last, post-apocalyptic hour of mankind.

In the lab’s studio, Holdorf was joined by several of PPA’s staff and a gaggle of students—advanced installers and service pros among them—for the fun, fast-paced training session. The evening’s broadcast topic: hydronic piping and circulation.

If you haven’t yet experienced the style of humor and education—the clash of laughter and learning that’s unique to Taco After Dark—you owe it to yourself to check it out. Don’t take my word for it—all of their sessions are archived; the stored broadcasts are almost as much fun as the live productions.

If you haven’t yet experienced the style of humor and education—the clash of laughter and learning that’s unique to Taco After Dark—you owe it to yourself to check it out. Don’t take my word for it—all of their sessions are archived; the stored broadcasts are almost as much fun as the live productions.

Holdorf, true to form for the broadcast, took just a slice of the full-day residential hydronics training class, served with a healthy measure of merriment. He and Barba—often in concert with Taco’s other trainers, Rick Mayo, Rich Medairos and Brett Zerba (Medairos + Zerba focus their efforts on commercial hydronic systems)—deftly held the attention of live and online trade pros.

Enraptured audience

It would be quite a challenge to educate and entertain a large, mixed group of hydronic techs, but not for Holdorf and Barba with just the right mix of antics, humor and trade secrets.

One young technician in the live audience for the PPATEC Taco After Dark broadcast was Owen Kunder, a mid-20s service and installation tech with Stevens, Pa.-based Vertex Mechanical. Kunder drove more than 30 miles to attend the live event.

“I haven’t had much training for boiler work yet, so being there for the broadcast was really exciting,” he said. “I learned a lot. One thing that stuck out was hearing Dave talk about system design, and the differing PSI levels that vary with building height. It was fascinating.

“I’ve been installing Taco components since I was 16, but wasn’t aware that they offered air eliminators,” he added. “I really enjoyed myself and will be sure to catch more Taco After Dark broadcasts.”

Kunder was soon joined by fellow Vertex installer, Jared Fox. After greeting each other, they spotted the boxes of pizza and then settled in for the “show.” Meanwhile, the live audience was admiring the immaculately-installed hydronic system that, two years earlier, Fox installed.

“This was a first experience for me with Taco After Dark,” said Fox. “I wasn’t sure what to expect, but when Dave got rolling, I was very impressed.

“[Holdorf] offered insights into why things are done certain ways when designing and installing hydronic systems,” continued Fox. “I learned a lot in a short period of time; he gave me a deeper understanding of concepts and practices that I thought I knew a lot about. I was also learning from his answers to my questions—and especially the questions of others. There’s always new stuff to learn, and this experience was super valuable.”

“Holdorf leaves you with a good, lasting impression,” said Eric Love, a technician with HB Home Services. “I’ll always recall that a circulator doesn’t move water—it creates a pressure differential between the inlet and the outlet.” Oh, the things that define the uniqueness of hydronics!

Remaining LIVE/on-location presentations of Taco After Dark

October 25: Flow, Heat and the Finer Points of Circulator Selection

The next step in building a great hydronic system is understanding the interrelationship between BUTH, flow, pressure loss (known as head loss) and pipe sizing. All of those ingredients go into proper circulator selection.

In this class, you’ll learn why there’s no such thing as one circulator for all applications, and how our industry actually has a chronic circulator oversizing problem. And we’ll also start the discussion on variable speed ECM circulators and why there’s no such thing as a circulator that sizes itself.

ON-SITE & ONLINE

New England Institute of Technology

1 New England Tech Blvd

East Greenwich, RI 02818

Wednesday, Oct. 25

7:00 pm EDT

November 1: ECM Circulator Essentials

ECM stands for Electronically Commuted Motor. And those three little letters are transforming residential hydronics. But do we really know what we need to know about how these remarkable little devices work?

Variable speed technology can do wonders for the modern residential hydronic system, but they’re not magic. They don’t size themselves and they don’t take the thinking out of circulator selection, no matter how many times you press that AUTO button. In this session, we’ll dispel the many myths and common falsehoods about ECM circulators. And we’ll show you the real value of these things will help you create the most efficient system possible for your customers.

7:00 pm EDT

Circulators or Zone Valves

If you were King of Hydronics and you could dictate to the industry how to zone a system, would you insist on one circulator per zone, or would you rule in favor of one circulator and zone valves?

It’s an age-old question, and in this session of Taco After Dark we’ll examine the pros, cons, realities, and myths of both options. And by the time the hour is up, we’ll provide you with the ultimate and definitive answer as to which one is better and why.

Wednesday, Nov. 8

7:00 pm EDT

November 15: Air-To-Water Heat Pumps and Low Temperature Hydronics

With the movement to “beneficial electrification” well underway, air-to-water heat pumps are becoming a factor in modern residential hydronics.

In this program, we’ll discuss how these things work, what they can (and can’t) do, and how to get into this rapidly growing business. You’ll also learn about the new Taco System M air-to-water heat pump and its unique capabilities.

ON-SITE & ONLINE

Johnson College

3427 North Main Ave.

Scranton, PA 18508

7:00 pm EDT

Register

Attendees may register for each session individually, and each program will be recorded and archived for later viewing. Each session qualifies installers for one PDH credit. (YOU MUST ATTEND ONE OF THE LIVE WEBINAR SESSIONS (NOT THE RECORDED SESSION IN ORDER TO RECEIVE THE PDH CERTIFICATE.) The link to the PDH certificate, along with a link to the recorded webinar session, will be emailed to you approximately 24 hours after the end of each webinar session.

David Holdorf

Residential Trainer, Eastern Region, Taco Comfort Solutions

Holdorf has been in the hydronic industry for 25 years, specifically in the radiant heating side of the business for the better part of his career. Starting out in the technical support/design role and then took over as Engineering Manager overseeing the Technical Support and Design Department. Later he took a position as a Field Technician; supporting training, designing, installing and troubleshooting.

John Barba

Director of Training, Taco Comfort Solutions

John Barba has been in the plumbing heating industry most of his life, growing up in his family’s plumbing and heating business in Harvard, MA. John’s practical experience includes everything from ditch digging and drain cleaning to boiler piping and PEX slinging, as well as business management and contractor sales. Since 1995, John has trained over 30,000 contractors on the fine art and subtle science of hydronic heating design and installation through highly interactive, entertaining and informative seminars.

He is the 2012-2014 recipient of the Carlson-Holohan Industry Award of Excellence, and was recently named the industry’s Best Trainer for 2015 by AHRI News Magazine.

Rick Mayo

Western Product and Application Instructor, Taco Comfort Solutions

Rick started his career in the hydronic heating industry as a plumber in 1977. In 1981, he transitioned into a wholesale role. Over the next 21 years, he worked his way up to a regional heating manager and left to pursue a training/technical support position with Uponor-Wirsbo. Seven years later, Rick took a western regional sales manager/corporate trainer role with Triangle Tube/ACV. Since joining Taco in 2015, Rick has made an impact as the Western Product and Application Instructor through his training that stretches from Alaska to San Diego, as well as four provinces in western Canada.

Richard Medairos

Director of Engineered Products and Systems Training

Medairos is a Senior Systems Engineer and Director of Commercial Training at Taco Comfort Solutions. He has over forty years of experience with demonstrated expertise in engineering, project management and planning. Throughout his career, he has worked on projects with major clients such as NASA’s Kennedy Space Center, Disney World, Universal Studios Florida, Boston University, Rhode Island School of Design, First Data Corporation, and Taco’s Innovation & Development Center.

Brett Zerba

Applications Engineer, Taco Comfort Solutions

Zerba is an Application Engineer at Taco Comfort Solutions with over twenty years of experience at the company. He graduated with his Bachelor of Science in Mechanical Engineering from the University of New Hampshire in 1981, and in 2003 he earned his Master of Business Administration from Johnson & Wales. Mr. Zerba has demonstrated his skill and expertise in the field of hydronic systems as an ASHRAE and Hydraulic Institute member.

As we make the transition from summer to fall, it’s important for HVAC contractors to ask themselves—am I prepared to meet increasing consumer demand for energy-efficient heating? In a marketplace that rewards companies that deliver products that are energy-efficient and cost-conscious, contractors should be up to speed on the latest offerings their customers may ask Read more

As we make the transition from summer to fall, it’s important for HVAC contractors to ask themselves—am I prepared to meet increasing consumer demand for energy-efficient heating?

In a marketplace that rewards companies that deliver products that are energy-efficient and cost-conscious, contractors should be up to speed on the latest offerings their customers may ask about—one of which being condensing boilers, an efficient alternative to traditional boilers that offer home heating and hot water.

So, what are condensing boilers and what benefits do they offer installers and consumers? Let’s find out.

What’s a Condensing Boiler?

A condensing boiler is a more efficient alternative to a traditional boiler and uses fuel to generate heat and hot water. In a non-condensing boiler, gases produced by burning fuel are released through a flue and, in turn, their heating potential is lost. A condensing boiler converts previously lost energy in the form of water vapor condensation into heat, recycling waste gas and delivering heating and hot water with high efficiency and low operating costs.

The condensing process allows these boilers to operate at up to 95% energy efficiency. By comparison, traditional boilers typically reach only 80-85% efficiency. They also consume 13% less fuel than a traditional boiler system. Plus, condensing boilers typically take up a smaller footprint than their traditional counterparts, offer increased control via digital dials and come with attractive installation rebates for homeowners and installers.

Long-term savings

Between 2015-2020, Bosch Home Comfort’s own market research reports an average yearly growth rate in condensing boiler installation of about 6.8%, due to several financial incentives.

Singular Combi Boiler

As upgrades become necessary in homes and businesses, many are opting for a condensing boiler to replace their traditional boiler and reaping the benefits. While condensing boilers can pose higher costs than traditional boilers up-front, their increased efficiency spurs savings over the life of the system, making them a popular and reliable long-term choice.

Additionally, there are several government incentives and rebate programs available for hot water boilers. Customers can take advantage of a 30% project cost tax credit through Energy Star that applies to Energy Star certified gas boilers with AFUE ≥ 95% or certain oil boilers.

Operational benefits

While many of the benefits of condensing boilers lie within the operation of the unit itself, there are also some other tangible advantages, including:

- Floor-mounted or wall-mounted options, allowing for increased flexibility in smaller spaces.

- User friendly controls. While most traditional boilers offer On/Off operation, condensing boilers allow users to modulate burners and set temperatures based on outdoor conditions, allowing the unit to operate more efficiently.

- Easier installation. Condensing boilers have a smaller footprint than traditional options, and since they are not cast iron, they are easier to maneuver and set up in a home or business.

Bosch Greenstar Boiler

Future Outlook

Condensing boiler technology has already been widely adopted in the industry and in homes and businesses across the country. Educating the public on their options for heating and hot water, as well as on maintenance and care for condensing boilers, will be key to continued growth and adoption.

Neglected maintenance is a major cause of failure for boilers. It is imperative consumers know what is required to service their systems, as well as who to call for maintenance and how often they need to schedule routine service checks.

The HVAC industry is sure to continue heating up in the coming years as more home and business owners consider making the switch to more energy-efficient comfort solutions.

Christopher Kyes is a Senior Product Manager for Bosch Home Comfort USA (formerly Bosch Thermotechnology), a leading source of high-quality, energy-efficient and environmentally sustainable heating, cooling and hot water systems. For more information, visit www.bosch-homecomfort.us.

Vetter Plumbing, that is. If you’re ever in the Pacific Northwest, look up Doug Vetter, owner of Vetter Plumbing, Longview, Wash., and successful plumbing and heating contractor who has worked with the tools almost nonstop since graduating from high school in 1990. We recently rain into Doug at the pipe-cutting ceremony for Uponor’s Experience Center Read more

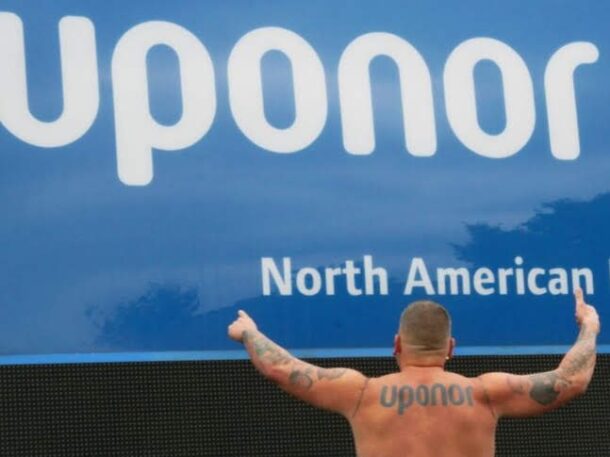

Vetter Plumbing, that is. If you’re ever in the Pacific Northwest, look up Doug Vetter, owner of Vetter Plumbing, Longview, Wash., and successful plumbing and heating contractor who has worked with the tools almost nonstop since graduating from high school in 1990. We recently rain into Doug at the pipe-cutting ceremony for Uponor’s Experience Center, and his passion for the trades is palpable.

Doug Vetter, right, has an infectious attitude, and enjoys living life like no one else.

In fact, you might say that young people searching for their true passion won’t likely encounter a more inspiring ambassador than Doug to a life in plumbing and heating.

There are, of course, a great many proud, highly accomplished professionals in this industry. But you’d be hard-pressed to find a tradesperson with a more robust and, at times, fearless outlook on life than Doug. He readily insists that much of this bring-it-on attitude derives from the sheer thrill of working as a service technician. “I just love my job,” he says over and over again.

For a small sampling of the sunny-side-up attitude Vetter brings to work each day, consider his morning routine of delivering doughnuts to the counter and warehouse staff at his favorite local supply house. Whoever heard of a plumber bringing free food to a wholesaler? “They have done lots of special stuff for me,” he cheerily reasons, “and, besides, it doesn’t cost that much.”

“My customers are always asking me, ‘Why are you in such a good mood today?’” he continues. “Well, when you contact me, we both know it’s not a social call. You have problems and fixing them may not be a ‘fun’ time for either of us. Why dump more stress on your situation by carrying a chip on my shoulder because I need to, let’s say, squeeze into your crawl space? Believe me, I hate crawl spaces. But being a plumber was my choice, and squeezing into crawl spaces is my job. That’s why you pay me.”

Doug willingly, happily, eagerly does his job 10 hours a day, seven days a week. But these are mere average—the actual totals could be much more in any given week. He would not have it any other way in a business that seldom lets him even slow down, let alone rest.

“I’ve never had a down time, even during the recent recession,” he says. “I just can’t say ‘no’ to people. That’s one of my downfalls and an issue with my significant other. But I love working.”

Back to the Uponor visit, Doug tells us that he is particularly proud of his tattoos, even the jaw-droppingly large U-P-O-N-O-R logo. Its six block letters span the full width of his back, left shoulder to right. Just as amazing: Every last ink mark strictly adhered to corporate style guidelines, right down to the correct shade of blue.

“I had a large blue Uponor sticker of the sort I put on my two trucks. I told my tattoo guy to put this exact thing on my back. He said, ‘Really?’ and I said, ‘Absolutely!’” Three grueling sessions over eight hours later, the tattoo was exquisitely in place and ready for show time whenever Doug decides to remove his shirt.

Why would he do something so “out there”? Why not? he shrugs. How better to express his unwavering loyalty to a brand he has supported nearly his entire career? “Uponor is the only brand I will put on my skin,” insists Doug, offering what is for him the ultimate compliment.

He fondly remembers his very first encounter with PEX more than 20 years ago, working for a Seattle plumbing wholesaler in the mid-1990s. Mark Walther — then a sales agent for the Portland-, Ore.-based Hollabaugh Brothers & Associates (still Uponor’s rep in the Pacific Northwest); and later a mentor for Doug when both worked at Merit Mechanical in Seattle—demonstrated the thermal memory of PEX with the familiar heat-gun demonstration that thousands have witnessed at countless trade shows over the decades.

Vetter’s work truck is radiantly heated.

“Mark said to me, ‘Watch this, Doug!’ After kinking the pipe in his hand, he used a simple heat gun to make that kink vanish in minutes. I will never forget that moment—it was the coolest thing, just incredible. Every chance I get, I love showing people the same demo with the heat gun.”

Doug readily embraces the problem-solving aspect of service work: “I love going into someone’s house, learning what’s wrong, explaining the situation in ways the customer can understand and appreciate, and then fixing the problem—and fixing it in the right way.

“I can’t just throw something together for a customer. I do my plumbing a certain way—the way I was taught all those years ago at Merit Mechanical, where I earned my journeyman’s license.”

As noted earlier, those young people you’re trying to steer toward a trade career won’t likely snag a first job with Doug, who has happily—defiantly even—worked solo for the vast majority of his professional life since starting his own business. Although, his wife, Liz, is going through her apprenticeship to join him as a licensed plumber in the business.

Vetter has a certain way of running his business. “I want my cords wrapped in a one-foot circle and put away in a particular spot. My truck, a big-box van, is spotless and organized a certain way, and I want to keep it that way. That one employee I had just couldn’t do it.”

Same thing for working with the tools, if not more so: “I’m not a hard ass, but my No. 1 job is to protect the health of my customers. If I fail to create a sewer-line joint properly, the customer will have a disaster. If I expand a pipe incorrectly, I’m flooding someone’s house. I do it right because my reputation depends on it, and my reputation is all I have.”

Another, equally critical facet of “Doug’s Way” is treating every customer the same—fairly and nicely. “Nobody, it seems at times, does customer service any more. For example: promptly calling someone back who has called you. I feel badly if a day goes by before my returning a call. Many don’t do it at all and think nothing of it.

“I was taught to treat people with the utmost respect, regardless of what they look like, where they’re from, or how much money’s in their pockets. I want to fix their plumbing, of course, but I also want to give them the best service they can get anywhere.”

Currently in his 50s now, Doug plans to work “until I just can’t do it any more”—before retiring to Puerto Rico, where he says the people are warm, the weather’s warmer, and the water’s warmest of all. Until then, he will stick to his 70-hour work week as a highly motivated service plumber who gladly shoulders more work than any one man should handle, despite doing no advertising or promotion other than word-of-mouth.

“I thrive on service work. I love the instant gratification of solving problems. I get up in the morning, hit the road to meet new people, and figure out how to help. Every job is different, and the days just fly by.”