Among hydronic/plumbing and mechanical professionals, there are a few trade pros who make their craft into an art form. Their work is so refined and deliberate that the finished work takes on the appearance of mechanical mastery. Tradesman and mechanical artist Orest Omeliukh is one of those. He’s drawn inspiration from the European approach to Read more

Featured Articles

Among hydronic/plumbing and mechanical professionals, there are a few trade pros who make their craft into an art form. Their work is so refined and deliberate that the finished work takes on the appearance of mechanical mastery.

Tradesman and mechanical artist Orest Omeliukh is one of those. He’s drawn inspiration from the European approach to mechanical system design, though with his own flair.

Orest Omeliukh

Across the big pond, hydronics are prolific, and mechanical components often see more human interaction than in North America. Components are sleek and clean looking, and installed within the occupied space instead of being relegated to cramped, dungeonesque mechanical rooms where resident spiders are rarely disturbed.

Omeliukh, who founded Blackrock HVAC Ltd. in 2014, was born in Ukraine, immigrating to eastern Canada at the age of three. His father was a tradesman who came to Canada to work on massive district systems.

“My Dad has designed underground steam mains up to 16 feet in diameter,” said Omeliukh. “He came here, to Mississauga, Ont., with 20 other mechanics, engineers and pipefitters. Half of those men stayed and raised families.”

Recent trips back to Ukraine, Switzerland, Germany, and various other European countries left an indelible mark on Omeliukh’s style of work.

“I build the Bentley of HVAC systems,” he explained. “The systems are complex in regard to what they accomplish, but they’re very simple for the service contractor and the homeowner. I only take on two custom home projects per year, and each is unique and aesthetically pleasing. But form follows function.”

Every Blackrock mechanical room has four key elements: components and system design that provide absolute premium comfort and efficiency, a feature wall, painted floors and LED lighting.

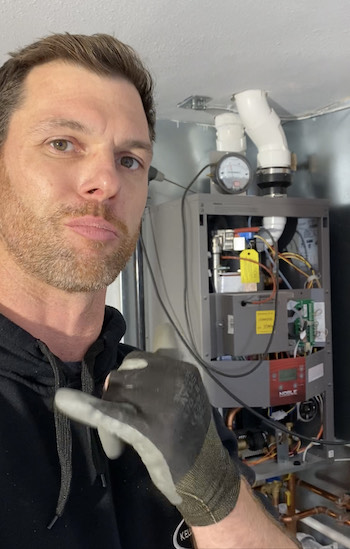

Orest Omeliukh, owner of Blackrock HVAC Ltd., finishes installing several circulators at the Gonell’s mechanical room.

In late 2017, Blackrock was approached by a custom builder, Gonell Homes, for a full gut remodel of a home in one of Tornoto’s older neighborhoods. Omeliukh had done work for the general contractor before, and the company’s owner, Will Gonell, hired Blackrock to design and install the comfort systems for his own residence.

“Will has been a mentor to me in a lot of ways,” said Omeliukh. “He’s an former U.S. Marine, so he has a very direct way of explaining things. He teaches and motivates simultaneously, with a wisdom beyond his years. When he asked me to build the mechanical system in his own home, he gave me full artistic license.”

War against bulkheads

Gonell’s two-story, 3,000-sq.-ft. home was stripped to the studs. The second floor was expanded to include a new master suite. Spray foam insulation and new windows were added throughout, and the domestic hot water recirculation line was insulated. Greatly reduced heat loss—Check.

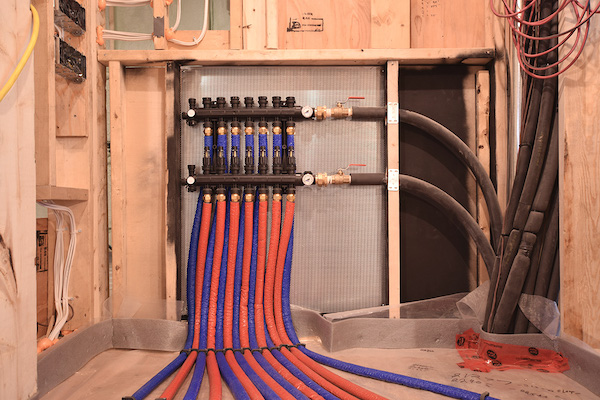

The concept that evolved between Gonell and Omeliukh was to use six zones of radiant in-floor for primary heat, and a seventh zone served by a hydronic air handler, which shares high velocity ductwork with a heat pump. Domestic hot water is also provided by sidearm tank. Snowmelt in the driveway also draws from the condensing boiler in the basement, meaning that Blackrock had to provide four different water temperatures.

The concept that evolved between Gonell and Omeliukh was to use six zones of radiant in-floor for primary heat, and a seventh zone served by a hydronic air handler, which shares high velocity ductwork with a heat pump. Domestic hot water is also provided by sidearm tank. Snowmelt in the driveway also draws from the condensing boiler in the basement, meaning that Blackrock had to provide four different water temperatures.

“This job was unique in that it was an old home,” said Omeliukh. “I wanted to show off the mechanical equipment within the mechanical space, yet eliminate it from view elsewhere. I call it ‘The War Against Bulkheads.’”

For air conditioning and backup heat, Blackrock installed a 2.5-ton Midea heat pump condenser paired with a Unico high-velocity air handler, allowing the branch ducts to be run within 2×4 stud walls. Proprietary sound attenuator branch ducts provide quiet airflow.

This air handler, along with the home’s Lifebreath HRV and an AprilAire 800 steam humidifier, is installed in a smaller mechanical space in the attic. Splitting the mechanical components between the basement and the attic was a tactic that helped Omeliukh win the War Against Bulkheads.

Masterpiece

“The basement mechanical room is the showpiece here,” Omeliukh. “Everything was selected carefully for function, then assembled in a manner that catches the eye, and provides ample room and lighting for service work. I used a ‘bunker’ theme here, as the room is like none other in the house, and really feels like a high-tech bunker.”

Will Gonell (left) with Orest Omeliukh in Gonell’s mechanical room.

Blackrock started with plywood walls covered in a very convincing poured concrete mural, giving the impression that each penetration was neatly core-drilled. In the past, he’s used murals portraying graffiti, art by Picasso, and a map of the Canadian Shield.

The 160 MBH IBC condensing boiler is piped primary-secondary. Omeliukh has calculated that the home’s heating load will only require 40 percent of the boiler’s capacity. When DHW or snow melt calls, the boiler will fire at 100 percent for rapid recovery. The rest of the time, it coasts along at low-load, condensing as intended.

The primary loop is circulated by a Taco Comfort Solutions 0018e circulator with Bluetooth capability. An identical pump is used on the 80-gallon indirect tank. This allows Blackrock to select between multiple constant speed, proportional pressure, and constant pressure modes as well as activeADAPT™, Taco’s self-adjusting proportional pressure mode.

The secondary loop consists of the eight heating zones: six radiant, one for the hydronic coil and one for the master bathroom towel rack. These zones are pumped by a pair of Taco VT2218 circulators, and use Zone Sentry valves for control. With the temperature sensing radiant circulators, Blackrock maintains a 20°F Delta-T. The zone valves are wired to expandable Taco zone controls, which communicate with tekmar WiFi thermostats.

The secondary loop consists of the eight heating zones: six radiant, one for the hydronic coil and one for the master bathroom towel rack. These zones are pumped by a pair of Taco VT2218 circulators, and use Zone Sentry valves for control. With the temperature sensing radiant circulators, Blackrock maintains a 20°F Delta-T. The zone valves are wired to expandable Taco zone controls, which communicate with tekmar WiFi thermostats.

“I use a lot of Taco products because of their reliability,” said Omeliukh. “They’re simple, the tech support is great, and the company culture breeds innovation and long term relationships.”

From the radiant manifolds in the downstairs mechanical room and two remote manifolds hidden neatly in the house, half-inch PEX was installed at nine-inch centers. This was poured over with a thin layer of Agilia lightweight concrete for optimal thermal performance and floor rigidity.

The system was designed with a -21°C (-6°F) outdoor design temp, and the boiler responds to actual conditions via outdoor reset for any heat call except DHW. Omeliukh insists the servicing the system is simple. He’s taken steps to ensure that those who come after him—whether a service tech or a homeowner —will agree.

Every zone features a label that was 3D printed in the Blackrock studio, and each loop has a pair of isolation valves. One wall of the mechanical room features a black box, wrapped in carbon fiber and illuminated with LEDs. This was for aesthetic purposes—simply to hide wires and piping that would otherwise clutter the installation. The box also contains piping and wiring diagrams.

Every zone features a label that was 3D printed in the Blackrock studio, and each loop has a pair of isolation valves. One wall of the mechanical room features a black box, wrapped in carbon fiber and illuminated with LEDs. This was for aesthetic purposes—simply to hide wires and piping that would otherwise clutter the installation. The box also contains piping and wiring diagrams.

“Unlike some contractors, I want the homeowner to be able to tweak the system or make adjustments in the event of an emergency,” explained Omeliukh. “And if a technician other than myself is going to work on it, I want to make their experience a good one.”

Pushing the limits

When Omeliukh dusts off his hands after a job, he goes home knowing that he’s done everything possible to deliver premium value. This mean taking extra, unconventional steps.

Gonell wanted discrete HVAC: highly visible only in the mechanical area, and invisible elsewhere. So, no t-stats; instead, Blackrock installed flush mount tekmar 084 sensors throughout the home. The tiny sensors are installed in a small indent in the drywall, then mudded and painted over. Wired to the tekmar 562 T-stats in the mechanical room, this approach allows occupants to manipulate temperature in any zone via an app, whether they’re sitting in the kitchen or at a tiki bar in Fiji.

The need for comfort paralleled Gonell’s desire for aesthetics. After installing radiant systems for years, Omeliukh’s recent visit to Germany reshaped the manner in which his company installs radiant tubing.

“If you look at an in-floor system through a thermal camera, you’ll find that loop ends are significantly cooler than the supply side. Most radiant installers use the “serpentine” method of laying tubing. While this is fast and easy, it tends to group all of the hottest pipe together, and same with the cooler loop ends. Lately, we’ve been using the ‘counter-flow’ layout, which is common in Europe.”

Blackrock insulates the pipe near his manifolds to avoid overheating the area.

The counter-flow design takes more planning and a little more time to install, but it alternates the warmest portions of a loop with the coolest across the floor. This provides even heat distribution across the floor.

“I like to push the limits on all our installations – it forces us to grow and develop new skills,” said Omeliukh. “On this job, that included a third tubing layout, which we’d never tried before: double-wall serpentine.”

The master suite featured two exterior walls. The double-wall serpentine method places the warmest portion of the radiant loop in close proximity to exterior walls, concentrating the most heat in the area with the most heat loss. It required some extra thought, and Omeliukh and his partners—as he calls the other HVAC tradesmen that he collaborates with on extensive projects—to pull tubing and re-staple it on one occasion.

Green elements

A tight building envelope, the latest condensing boiler technology and a full suite of ECM-powered circulators were just the starting point for efficiency at the job Omeliukh has dubbed “Operation Gonell.” He wanted maximize the efficiency.

The HRV is a whole-house system, connected to each of the home’s five bathroom fans. This is required by Ontario Building Code, but Blackrock took energy recovery one extra step. The unit is just an HRV chassis. During the summer, an ERV core is installed in the unit. Come heating season, the ERV core is swapped with an HRV core. This method provides optimal energy transfer regardless of outdoor conditions.

The HRV, Unico air handler and the steam humidifier share an impressive, insulated mechanical space in the attic, technically making that room an occupied space. So it needs to be conditioned during the winter. Blackrock had a plan for this.

“Boiler rooms are inherently warm,” said Omeliukh. “Too warm, for most of the winter. So we installed a central bathroom exhaust fan in the boiler room to move “free” warm air into the attic mechanical room. It’s energized by a thermostat when the temperature in the boiler room reaches 78°F, and does a fantastic job of maintaining a conditioned atmosphere in the attic. Blackrock calls this use of waste heat a “hybrid innovation.”

Finally, Blackrock took several steps to ensure that domestic hot water is provided efficiently. DHW lines were insulated, and the Taco 006e3 circulator used for recirculation is plugged into a SmartPlug control.

Using a sensor that mounts to the hot water supply pipe, the SmartPlug “learns” the daily hot water usage pattern in a home and adjusts the circulator run time to deliver hot water when needed. When usage patterns change, the SmartPlug adjusts run times automatically.

Blackrock also installed a ThermoDrain DHW preheat system. It includes a three-foot section of copper drain with an integral copper coil, and is installed on the main plumbing stack. Supply water to the water heater first passes through the ThermoDrain, collecting waste heat from the stack as an occupant showers. The Gonell home has five residents, with two teenagers, so being able to collect some of the heat is a bonus.

Blackrock also installed a ThermoDrain DHW preheat system. It includes a three-foot section of copper drain with an integral copper coil, and is installed on the main plumbing stack. Supply water to the water heater first passes through the ThermoDrain, collecting waste heat from the stack as an occupant showers. The Gonell home has five residents, with two teenagers, so being able to collect some of the heat is a bonus.

It’s pretty common to receive HVAC permit drawings that don’t reflect the structure or meet mechanical space requirements – especially on renovation projects,” said Omeliukh. “Because of that, communication between the designer, all the trades, and the equipment manufacturers was crucial on this project.”

“Gonell and I both wanted to use the best of the best component on this system,” he continued. “He gave me free reign to push my limits and incorporate everything I wanted to. From there, we just let all the elements fall into place.”

I’ve always had this romanticized view of Alaska. Ahh, The Last Frontier. It’s been on my bucket list for years, and it was actually one of the places my father and I had initially planned to visit before he passed away. There is something mystical about it — the beauty of the mountains, the wildlife, and Read more

I’ve always had this romanticized view of Alaska. Ahh, The Last Frontier. It’s been on my bucket list for years, and it was actually one of the places my father and I had initially planned to visit before he passed away. There is something mystical about it — the beauty of the mountains, the wildlife, and I would think you would have to have something special to live and work there. “Living in Alaska is an adventure. It is an extreme place to live with beautiful amazing summers with almost 24 hours of daylight to extreme cold, dark, snowy winters. There is no shortage of extreme activities to choose from,” says Everett Knudsen, owner/operator, 907 Heating & Plumbing, Anchorage.

Working in Alaska is extreme as well, says Knudsen, especially for the heating and plumbing trade. “Extreme cold (-20 F) is not uncommon in Anchorage January through February, and even colder in more northern locations of Alaska (-50 to-70 F). I’ve had a project that required taking a helicopter to get to the job site and another that required taking a boat,” says Knudsen.

“I used my own boat to travel back and forth to the jobsite over the course of about a week and a half. When we launched the boat there was about 6” of snow on the boat launch and had to chain up the box van just to get the boat in the harbor. Then the harbor was frozen over and one person had to sit on the bow with a piece of steel pipe and break up the ice in front of the boat to get the boat out of the harbor. The boat ride to the jobsite was out of Valdez harbor through the Bay to the Narrows. The mountains come right into the water, and just an amazing 30-minute commute.

“I used my own boat to travel back and forth to the jobsite over the course of about a week and a half. When we launched the boat there was about 6” of snow on the boat launch and had to chain up the box van just to get the boat in the harbor. Then the harbor was frozen over and one person had to sit on the bow with a piece of steel pipe and break up the ice in front of the boat to get the boat out of the harbor. The boat ride to the jobsite was out of Valdez harbor through the Bay to the Narrows. The mountains come right into the water, and just an amazing 30-minute commute.

“On our final trip back at the end of the project was very dangerous, the weather had turned very bad with high winds and blowing snow. We didn’t want to be stuck on the remote jobsite any longer so we went for it. The waves were 8-12’ and it was blizzard conditions. For my 22’ jet boat we were in way over our heads. Any type of engine failure would surely cost the two of us our lives. We could barely see the glimmer of the harbor lights as we slowly pushed through the storm. The windshield of the boat was freezing over and we could barely see. The boat was crashing over each wave and the spray was freezing and build up on the boat. I was terrified, as was my helper. Luckily, we made it back safe, very shaken, but safe. It was an experience I will never forget. You have to respect the extreme of Alaska or it could get the better of you.”

Plumbing in -20 F degree weather is very difficult and can be dangerous, reiterates Knudsen. “I’ve had my Channellock pliers freeze/stick to my gloves. I’ve entered houses full of ice from frozen split pipes. Working outside requires wearing the appropriate gear, and sometimes I’m only able to work outside for 30 minutes at a time before getting too cold. “Sometimes I have to use a pipe thaw machine (buzz box) or large welder to thaw frozen pipes to restore domestic water or heat. And usually this means wet gloves and hands, which does not match well with freezing temperatures,” says Knudsen.

Needless to say, frozen cordless tools—mainly batteries—have to be kept inside once it gets colder than 20 or so and calls at all hours of the night, and working long late hours because time is of the essence to avoid more damage to property when it is very cold out, is imperative.

But what about the occasional wildlife encounter? Typically, while working in Anchorage it is safe, says Knudsen. There is frequent moose and the occasional bear, and depending on the part of Anchorage, there can be some added risks in the suburbs, he adds. “Springtime is always a good time to be cautious. The moose are having their babies and mama moose are very protective of their babies. Also, bears are coming out of hibernation and looking to eat anything. Yet, in my 25 years in Anchorage, I have not had a problem with either moose or bear.”

There are usually 1-3 or more bear attacks each summer in and around Anchorage. It is important to be aware of your surroundings in the summertime. “In the summer, when I go hiking anywhere in Alaska, I carry a 10mm or 44mag pistol for bear protection. Surprising a bear in the wild is where the problems lie and you never know when that will happen and it’s better to have it and not need it, then need it and not have it,” says Knudsen.

Into the Wild, and into the Trades

Originally from the Northwest, Knudsen, moved from Olympia, Wash., to Alaska in 1994. Knudsen answered a help wanted ad in the Anchorage local newspaper back in 1998 for “Local Plumbing Company Seeking Shop Helper.” He was 19 years old. “I started at Anchorage Plumbing & Heating, and at that time it was not my intention to be a plumber or have a plumbing career, I just needed a job, and I didn’t mind labor-type work.

Bottom line, Knudsen started a family at a very young age and needed to provide for them. “My son was six months old when I started plumbing at age 19; eight years later my daughter arrived. Family was my main drive to become successful and work the hardest I could. I wanted to provide the best environment for them that I possibly could, while setting an example of honesty, hard work and determination as an ethical backbone for success,” says Knudsen.

Bottom line, Knudsen started a family at a very young age and needed to provide for them. “My son was six months old when I started plumbing at age 19; eight years later my daughter arrived. Family was my main drive to become successful and work the hardest I could. I wanted to provide the best environment for them that I possibly could, while setting an example of honesty, hard work and determination as an ethical backbone for success,” says Knudsen.

At that time, Knudsen didn’t have a clue about how plumbing or heating worked, or how vast and essential it really was. “Turns out that I was gifted with a solid mechanical inclination and I caught on very quickly. Within two months, AP&H put me in my own van and started having me do basic plumbing and heating service calls. From there I worked for two other companies over the course of eight years. At year five—shortly after getting my journeyman’s license—I learned I could get my own plumbing contractor licenses so I set my sights on completing that goal. This goal was big for me since I didn’t have any type of formal education. I acquired my Mechanical Administrators License in the Unlimited Plumbing category for the state of Alaska. Then I acquired my Anchorage City Contractor’s License and started working for myself.”

Knudsen has been self-employed for the past 13 years as a one-man shop, with occasional hired experienced help along the way when needed. He has done all types of work throughout his career; he started with residential service and repair work, which includes retrofit of boilers, forced air furnaces, fireplaces, water heaters, as well as regular maintenance, remodels, repairs of heating and plumbing systems.

A catalog of his work includes: Residential gas boilers including baseboard heat, radiant heat, flat plate exchangers for snow melt and pool heating, multi temp injection systems, commercial snow melt 10,000 sq. ft., 3 x 500k Knight boilers; oil boilers residential and commercial; brazed 3” copper and worked with 2” REAHU PEX; installed/replaced forced air furnaces of all types from closets to crawl spaces; HRV installation to maintain good air quality in our cold climate; retrofit/upgrade hot water system in 30 unit apartment building cut fuel and water usage by 50%; new construction on several custom homes, triplexes, duplexes, and single family homes; low voltage controls of all types. I do enjoy wiring controls; water heaters of all types and sizes; HDPE butt fusion and saddle fusion for new water supply to subdivision; multiple large generators, fuel lines, exhaust piping, fresh air supply—24” VFD fans—and ducting to exhaust radiator heat out of building; 25-unit trooper housing complex in Bethel, Alaska; and HRV for FAA Housing in Nome, Alaska.

And occasionally, he does some new construction projects here and there. “Service work is very rewarding for me. To help a homeowner resolve their heating and plumbing challenges and provide excellent customer service never gets old to me. The vast majority of customers are very happy to receive excellent service and are happy to pay for the service provided. It’s a win-win situation, I enjoy this type of situation, as does the customer.”

And occasionally, he does some new construction projects here and there. “Service work is very rewarding for me. To help a homeowner resolve their heating and plumbing challenges and provide excellent customer service never gets old to me. The vast majority of customers are very happy to receive excellent service and are happy to pay for the service provided. It’s a win-win situation, I enjoy this type of situation, as does the customer.”

And that’s one the biggest ethical factors that Knudsen has based a lot of his business principals on: Treat every project as if it were his. “I put myself in the client’s shoes, asking myself the question, ‘how would I want this to go if I was the client’ or the golden rule, ‘treat others as you wish to be treated.’ I was raised with a couple of core principals—hard work and respect. Applying these principles and ethics in my plumbing career has grown into something that has provided me with numerous lessons for personal growth, and a good income as well.”

What does Knudsen love most about his job? “I love building something with my hands and mind, then having a client look at the work and saying, ‘Wow, that looks amazing; how come the other plumber didn’t do that?’”

Again, Knudsen loves the win-win aspect of the job. “I love a customer that is super appreciative and complimentary, and at the same time, I’m making a living. This career constantly gives me opportunity for professional and personal growth. It enables me to learn new plumbing techniques, learn new customer relation skills on each job, and the scene always changes with new challenges every day. I love the variety.”

But what are the issues Knudsen sees in the trades that need addressing? Honesty, Integrity and Craftsmanship, says Knudsen. “These are the things that I saw missing as I was coming up in the trade, and I still see quite a bit of it missing today, especially in residential work. Too many plumbing businesses/contractors influence customers into work or products they do not need. Then do marginal quick installs to maximize profits and move to the next.

But what are the issues Knudsen sees in the trades that need addressing? Honesty, Integrity and Craftsmanship, says Knudsen. “These are the things that I saw missing as I was coming up in the trade, and I still see quite a bit of it missing today, especially in residential work. Too many plumbing businesses/contractors influence customers into work or products they do not need. Then do marginal quick installs to maximize profits and move to the next.

A lot of Knudsen’s learning has been on-the-job training. To him, that means the client has paid for his education as a tradesman. He does his best to honor the valuable experiences he has gained while working for clients. If there is a situation where Knudsen made a mistake due to lack of experience or making an assumption and was incorrect, he makes sure not to charge the customer for that time for two reasons: 1) They are paying for an experienced professional to resolve their problem correctly and efficiently. 2) The value of the experience will vastly outweigh the few extra dollars he would have made on that one job, by giving me the experience for the jobs to come in the future. “Doing the right thing when no one else will know is HUGE!! That is true integrity!”

Knudsen advises to do your best to take pride in your work whenever and wherever you can. “Unfortunately for plumbers and mechanical workers, our work is buried in the ground—a wall, a crawlspace, a mechanical room—where not much of its glory and existence is on display. Even so, still take the time to have a clean, proper, well-installed system, even if it is to be covered up, it is still about integrity and pride in craftsmanship,” says Knudsen.

The trades are a wonderful opportunity for young people not really sure what they want to do with themselves, says Knudsen. Regardless, adds Knudsen, young people will need to work, and getting into a trade is super valuable, not to mention they will get paid to learn. “I do not think there is another situation that can compare to the benefit of getting paid to learn a trade. A trade is not any less important than a doctor, lawyer or any of the other careers that require a college degree. For several years, in the early stages of my career, I felt less than because of my lack of schooling. Now, that lawyer whose heat is not working calls me to come fix it. Trade workers are just as smart and valuable as the next. Just because school isn’t for you doesn’t mean you’re not smart and can’t make a good living,” says Knudsen.

Work/Leisure Time Tilt

How does Knudsen balance work and leisure time? That has taken a lot of practice, says Knudsen. “But learning to say ‘no’ has been the key to that. It’s been difficult to learn that, especially being in business for myself. Even some of my longest, best customers have helped me learn this. It has been truly difficult to tell them no at times. I don’t do it often, but it happens, even so they are still my loyal customers. I’ve discovered that is the key to not having my business/schedule own me and for me to own my business/schedule. There is a right time and a wrong time to say no, but it takes practice to learn those moments to help maintain balance in life,” says Knudsen.

Social media is big for Knudsen (@907plumber on Instagram). He has just gotten into social media the last couple years and overall, he says it has been wonderful. “The Instagram community is amazing IMO. Big shout out to the IG community you all ROCK!”

Social media is big for Knudsen (@907plumber on Instagram). He has just gotten into social media the last couple years and overall, he says it has been wonderful. “The Instagram community is amazing IMO. Big shout out to the IG community you all ROCK!”

Knudsen was actually feeling burnt out after his second shoulder surgery and contemplating trying something different for work— not trade related. Since Instagram has been such an amazing thing because it truly brought new life into his plumbing career. All the positive feedback from people all over the country and world has impacted him in a way he has not experienced before.

The growing of the followers, winning giveaways, connecting with others who do the same things he is passionate about everyday has brought a new shining light into his life, and for that, he is forever grateful. “I’ve learned so many new things through Instagram and it grows every day. It also has helped give me more of a sense of accountability and confidence I didn’t have before. I cannot believe people want to watch little ole’ me doing my thing, but I guess they like it, and being a service provider, I like to give people what they want. Additionally, If I can encourage or motivate someone to become a better version of themselves so they can experience a better quality of life and for all who they come in contact with, that is a true blessing,” says Knudsen.

Physical Fitness

Speaking of the shoulder injury and a demanding skilled trade, Knudsen puts a heavy emphasis on fitness. “I have only really incorporated fitness into my regular routine in the last several years and I have noticed tremendous benefits. Three years ago, I had surgery on my left shoulder for torn rotator cuff and torn bicep and four years before that I had the same surgery on my right shoulder. I’ve had to do quite a bit of physical therapy to get my shoulders back in working condition. I’ve also developed some tendonitis in my elbows in the past couple years. I’ve done several sessions with a physical therapist for my elbows. The therapist essentially told me that my poor posture was contributing to my elbow pains.

So now I’ve added regular fitness to maintain strength in my shoulders and core to reduce fatigue and improve posture during the day. A good portion of my exercises also incorporate strengthening muscles for good posture to reduce added stress on shoulder, elbow and wrist joints. We are constantly working on stuff right in front of our chest causing poor posture and unbalanced muscle development. This leads to fatigue, joint soreness and injuries.

So now I’ve added regular fitness to maintain strength in my shoulders and core to reduce fatigue and improve posture during the day. A good portion of my exercises also incorporate strengthening muscles for good posture to reduce added stress on shoulder, elbow and wrist joints. We are constantly working on stuff right in front of our chest causing poor posture and unbalanced muscle development. This leads to fatigue, joint soreness and injuries.

“We are working in awkward positions, pushing, pulling, lifting, twisting, bending. When we are in our younger years it seems that the need for fitness is not very important. Our bodies are fresh and more resilient but the longer we are in the trades the more wear and tear on the body happens, especially after 20+ years in the field. Fitness helps increase on the job performance, stamina, reduces potential for injury, helps with mental health and focus as well.

My goal is to maintain my ability to work in the field efficiently for many years to come. Hopefully my post about fitness helps some tradespeople to avoid injuries and discomfort while adding new vigor to their work and personal life,” says Knudsen.

In addition to performing better on the job, that dedication to fitness allows Knudsen enjoy the array of outdoor activities that Alaska has to offer, which include fishing for salmon and halibut, boating in the numerous sounds, inlets, bays, lakes, rivers and ocean all around Alaska, hiking, camping, wildlife viewing, exploring, snowboarding, snowmobiling, ATV adventures.

In addition to performing better on the job, that dedication to fitness allows Knudsen enjoy the array of outdoor activities that Alaska has to offer, which include fishing for salmon and halibut, boating in the numerous sounds, inlets, bays, lakes, rivers and ocean all around Alaska, hiking, camping, wildlife viewing, exploring, snowboarding, snowmobiling, ATV adventures.

“I love outdoor activities. Much of my spare time has been spent outdoors. For many years boating, camping and fishing all around Alaska was my summer time activity. Then snowmobiling and snowboarding in the winter. I’ve had the wonderful opportunity to see some of the most beautiful places and scenes Alaska has to offer while enjoying these activities.

And it’s that Alaska mystique I spoke of earlier. When asked when was the last time Knudsen said it was a great day? “I feel like it was somewhere around a week ago driving. It was just one of those days where it was crisp, clear beautiful weather, and the music was right. Thinking about all the people, experiences and moments that make me feel grateful to be alive; to have an opportunity to get to see the future unfold in front of me.”

When premium wholesale plumbing supplier, Winston Water Cooler, decided to build a large training and distribution center in Phoenix, not only did they choose to stock Viega products, but they chose to show them off in their own plumbing and piping as well. The 35,000-square-foot building was recently completed for use with customer training. “The Read more

When premium wholesale plumbing supplier, Winston Water Cooler, decided to build a large training and distribution center in Phoenix, not only did they choose to stock Viega products, but they chose to show them off in their own plumbing and piping as well.

The 35,000-square-foot building was recently completed for use with customer training. “The Workbench” gives tradespeople the opportunity to do hands-on product demos and learn about the situations they might find on the job, as well as learn about products they can use.

“This is all live fire,” explained Phillip Clark, Partner of Winston Water Cooler in Phoenix. “There is water pumping through the heaters, gas running to the heaters, that sort of thing. We can simulate certain problems by putting different parts in and having people troubleshoot to find the issues. It’s all hands-on, which makes it valuable in our industry for these guys. We want them to be comfortable with the products, and it gives them a comfort level so they can come up here and screw up something instead of potentially screwing up their customer’s stuff!”

Clark said the training center includes products seen in multifamily buildings, plus parts of a mechanical room setup, including boilers, booster pumps and mixing valves. The building contains equipment supplied by a variety of manufacturers. Originally a data center, Winston remodeled the space into a training center.

All the water in the building is piped with ProPress, and gas lines are run with MegaPressG. About 200 feet of 2½” and 3” copper lines connect to storage tanks, where water can be circulated through heating and pressure-boosting segments. The gas lines have 1½” MegaPressG fittings.

“We wanted to become a stocking distributor for Viega for years, and in 2019 we jumped at the opportunity when it came,” Clark said. “We phased out Apollo as we brought in Viega. We realize the value in the product and know it’s good – and that a lot of customers only trust Viega.

“The product line with Viega is more diverse with the larger-diameter fittings, and Viega has some fittings in configurations and tighter tolerances. It’s just a good market presence that speaks for itself. We’ve had issues with other [brands], where we’re responsible for going back and taking care of the customer after hours. But Viega’s track record for quality and consistency is far superior to the competitors’ and it makes our customers happy.”

Clark said it’s a great advantage to hold training classes and show products at work that they also have in stock on their shelves. Attendees can see how Viega fittings work and that they’re a clean installation. All the piping in the facility is exposed on the walls and anchored so it can be used for show-and-tell.

These days have been pretty busy for Bulldog Contractors. “When COVID first appeared, there wasn’t enough hours in the day to get everything accomplished. And once stimulus checks hit, there was a huge spike in work flow. We have been very blessed and fortunate to be working through the pandemic,” says Jeff Keller. A licensed Read more

These days have been pretty busy for Bulldog Contractors. “When COVID first appeared, there wasn’t enough hours in the day to get everything accomplished. And once stimulus checks hit, there was a huge spike in work flow. We have been very blessed and fortunate to be working through the pandemic,” says Jeff Keller.

These days have been pretty busy for Bulldog Contractors. “When COVID first appeared, there wasn’t enough hours in the day to get everything accomplished. And once stimulus checks hit, there was a huge spike in work flow. We have been very blessed and fortunate to be working through the pandemic,” says Jeff Keller.

A licensed master plumber, Keller works for his father in running Bulldog Contractors in northeast Texas. Bulldog Contractors is a well-rounded company that strives to provide a one-stop shop for its customers, and that’s why Keller specializes in service work for plumbing, electrical and septic, and carries multiple licenses in electrical and septic as well.

Yet, the career path for Keller wasn’t always defined early on. When Keller was in high school, he wanted to be a veterinarian based on his love for pets and animals. “I honestly didn’t have the grades for it, so if I had to guess, I would be in the oil field chasing that dollar,” says Keller.

But watching his father succeed in business—and life—was huge for Keller. “I honestly never thought of following in his footsteps growing up. But as I got older, and needed a summer job, I fell in love with the overall variation of different types of jobs and people I encountered on a day-to-day basis,” says Keller.

But watching his father succeed in business—and life—was huge for Keller. “I honestly never thought of following in his footsteps growing up. But as I got older, and needed a summer job, I fell in love with the overall variation of different types of jobs and people I encountered on a day-to-day basis,” says Keller.

To Keller, his father was his biggest motivator. “He put me on a higher pedestal than I would have liked growing up as a kid, but in the end, it turned out very well and it kept my mindset on track. Also, some very deep guidance was from my grandfather—on my mother’s side—as well. The advice, stories, and memories that I have retained has been priceless. If I could be half the man my grandfather was …. they just don’t make them like they used to!” says Keller.

Keller has never looked back as his love for the trades has grown over the years. “In the service industry, you just never know what you are getting yourself into that day,” he says. “I like the uncertainty. The jobs are never identical. It keeps you on your toes and the mind busy,” says Keller. Oh, and as for Keller’s love for animals? “With my current career, I get to see multiple houses a day and their pets; I bond with them and that’s a cool small aspect of my day.”

Moving the Trades Forward

Concerning to Keller about the trades, though, is the quality of work and labor. “With the trades dying, so does the manpower to get projects completed. So, it’s a rat race to get in and out and onto the next one. Years or even sometimes months down the road we are fixing issues that could have been resolved if some time and quality was put into a job,” says Keller.

Concerning to Keller about the trades, though, is the quality of work and labor. “With the trades dying, so does the manpower to get projects completed. So, it’s a rat race to get in and out and onto the next one. Years or even sometimes months down the road we are fixing issues that could have been resolved if some time and quality was put into a job,” says Keller.

One of the biggest concerns for the trades overall is to infuse young, skilled labor into the trades. “It’s all about advertising and education; they go hand-in-hand. We really need to be getting into the school systems and reaching out to the youngsters. With the way this world is going at this moment, this will be a never-ending battle and a hard one to tackle. ANYTHING is possible, though!”

And when those recruits are ready, Keller suggests not going to school—unless required—to learn the trades, especially if you are going into the service industry. “What a service technician knows and understands isn’t taught in a book. Get into the trade, get your eyes and ears in the field, and become a sponge. Learn everything you can,” says Keller.

Work/Life Tilt & Spare Time

Balancing family time and work is often tough to navigate. Keller’s family understands that sometimes the phone rings and he has to take the call, yet he will always make time for them. There will be work and money to be made, regardless, says Keller and his family is the most important thing that he has and cherishes.

“Some days I make a lighter work load to pick the kids up from school and take them on a field trip, or doctor appointments. I took my middle girl, Elyse, out to ice cream the other day, just us. The little things are what they will hold onto and remember for years to come. My father did the same for me and I plan to pass that onto my family, as well. You must make time for your family because the kids will be grown and gone before you know it,” says Keller.

“Some days I make a lighter work load to pick the kids up from school and take them on a field trip, or doctor appointments. I took my middle girl, Elyse, out to ice cream the other day, just us. The little things are what they will hold onto and remember for years to come. My father did the same for me and I plan to pass that onto my family, as well. You must make time for your family because the kids will be grown and gone before you know it,” says Keller.

For Keller, though, it’s hard for him to sit still so you’ll normally find him in the shop tinkering around mostly cleaning and keeping it organized, and playing with the kids. “The same with my yard, I’ll go mow dirt if I have time! It’s my quiet place if you know what I mean. On the weekends, I enjoy my main hobby, which is fishing—mainly night fishing so the wife and kids sleep through most of it while I’m gone,” says Keller.

Social media has opened many doors for Keller that he would have never imagined. “If someone told me 10 years ago, I would be traveling all over the country—anything from factory tours to trade shows to attending early tool/product releases, I wouldn’t have believed them. I appreciate all the new friends and connections I have made. It’s a true honor.”

What people may not know about Keller is, “I’m a nerd when it comes to numbers and efficiency of my house. During a day I might check the water pressure of my house 2-3 times. Same goes for my current water heater temp—digital display on heat pump unit. And my solar input and output. I keep a close eye on efficiency.”

The last time Jeff Keller said “today is a great day”? “I took off work super early, surprised my wife and we went out and about for the day, no schedule at all.”

BY JOHN O’REILLY 35-year industry veteran discusses why his employer, CPI Plumbing & Heating, has chosen to invest heavily in developing the tech skills of local high school grads, working with various vendors and suppliers to create a 2,500-sq.-ft. learning facility from scratch. The headlines tell the story with increasing urgency: The shortage of skilled Read more

BY JOHN O’REILLY

35-year industry veteran discusses why his employer, CPI Plumbing & Heating, has chosen to invest heavily in developing the tech skills of local high school grads, working with various vendors and suppliers to create a 2,500-sq.-ft. learning facility from scratch.

The headlines tell the story with increasing urgency: The shortage of skilled workers in the trades hampers our economy. Work takes longer to complete and costs more because of inevitable delays and fierce competition. This list of reasons why this shortage has reached critical mass is as long as your arm. What isn’t as clear is what to do to correct it.

The headlines tell the story with increasing urgency: The shortage of skilled workers in the trades hampers our economy. Work takes longer to complete and costs more because of inevitable delays and fierce competition. This list of reasons why this shortage has reached critical mass is as long as your arm. What isn’t as clear is what to do to correct it.

That is, unless you’re Steve Murray, a 35-year veteran of the PHCP industry and currently HVAC Division Manager at CPI Plumbing & Heating, a full-service contractor based in Mt. Vernon, Washington, a 60-mile drive north of Seattle on Interstate 5. For Murray and CPI owners Brad Tully and Michael (Oly) Olsen, developing a team of properly trained plumbing and HVAC service technicians is a task just as important as—if not prerequisite to—successfully managing the day-to-day operations of this fast-growing company.

The key to the company’s training effort lies in its recently completed “Training Lab” where young apprentices get to practice the skills taught in the company’s classroom. To outfit the 2,500-square-foot space with the plumbing, hydronic and forced-air HVAC systems the company installs and services, CPI went to the vendors that they rely on every day.

Among the most critical was Uponor North America, because its PEX-a piping and fittings offering are at the core of the company’s plumbing and heating disciplines. Uponor responded in a big way: donating nearly $5,000 of Wirsbo hePEX plus pipe for radiant and hydronic heating applications, as well as fittings, manifolds and controls. Also included was nearly 200 linear feet of Quik Trak plywood panels, used mainly for retrofitting a residential space with radiant heating.

“The CPI Training Lab has been a significant investment for us,” says Murray. “We spent $25,000 to $30,000 outfitting the space. Thanks to Uponor and our other vendor partners, we’ve been able to get much of the material donated. But it is a serious expense, for sure—yet one that we think will pay off, long term.”

In the following interview, Murray tells how CPI ensures it has access to a ready and reliably stable of service technicians, as well as how his background positioned him to lead this important initiative for CPI.

Question (Q): How did the idea for the training room develop?

Steve Murray: The closest training center to Mt. Vernon is 50 miles away, and it isn’t practical to ask guys who have already worked a full day to drive 90 minutes in rush-hour traffic to get to a training class. While there are a few local colleges with some HVAC classes, there is nothing in plumbing. Nor did the available curriculum offer any hands-on learning, which we believed essential.

We started by expanding an existing classroom and outfitting it with all the newest audio/visual equipment for online learning. Next, in 2018, we began to transform a junk space every contractor’s shop has into a hands-on lab where apprentices could actually practice what was taught in the classroom. We can now accommodate up to 30 students at one time. Our top techs, Coady Pike and Jake Petterson, help with the training and the curriculum planning as well.

We started by expanding an existing classroom and outfitting it with all the newest audio/visual equipment for online learning. Next, in 2018, we began to transform a junk space every contractor’s shop has into a hands-on lab where apprentices could actually practice what was taught in the classroom. We can now accommodate up to 30 students at one time. Our top techs, Coady Pike and Jake Petterson, help with the training and the curriculum planning as well.

To create an authentic environment, we framed a floor above existing plumbing connections for waste and water connections. The renovated space now has full plumbing facilities: a working bathroom, urinal and kitchen. We also have all the mechanical systems our techs work on in a home: two combi-boilers, two furnaces and air handlers, an electric furnace and, with Uponor’s help, radiant heating on the wall. We also have all kinds of water heaters, tank and tankless.

Q: What is your background and how did you gravitate to training?

Murray: After high school, I joined the Coast Guard. The trade skill in that branch of the military is called “damage control.” On a ship, damage control involves everything from firefighting, to taking care of plumbing systems, to welding and carpentry. That’s where I learned how to maintain plumbing and hydronic systems.

After five years, I left the service and got a job working for a maintenance/property management company, maintaining large apartment buildings in the older part of Seattle. From there, I worked for various contractors, becoming a journeyman plumber and HVAC service technician. Eventually, I opened my own shop for a time.

The one constant at every company, including my own, was a need for trained personnel. Most applicants lacked the necessary skills; or, worse, they had really bad habits. So, I started devising in-house training programs.

At the same time, I taught the plumbing apprenticeship track at a local trade organization called the Construction Industry Training Council. Working two jobs and commuting two hours each way for work eventually became too much. So, in 2016, I joined CPI, which is just 10 minutes from my house.

The owners wanted to grow their HVAC business, and I took on the role of HVAC Division Manager. We’re still working to grow it, and it has been a challenge, mainly because we just don’t get a lot of already properly trained candidates. That’s really what it boils down to.

Q: Who are the students and how do you find them?

Murray: Most are high school grads who CPI has hired. The average age of our apprentice crew is 20, although the average apprentice nationwide is 27, so we’re significantly below that.

Recruitment isn’t easy. Our marketing person participates in all the Chamber of Commerce meetings and all the local contractor trade groups. Last year, we started an outreach program to the local high schools, hosting meet-and-greets at the schools with graduating seniors, talking to them about the opportunities in the trades. We also host monthly open houses for interested kids and their parents. They tour the CPI Career Center and talk about what it’s like to work in the trades. That is really our best opportunity.

There is no perfect system to find the right people, and it is pretty easy to get disillusioned. So many high school guidance counselors still think every student needs to go to college to have a meaningful life. It makes no sense to me. Kids need to hear the message that the trades are a real career option that can provide a good living, post-apprenticeship training.

Q: How many young people are a part of the CPI apprenticeship program right now? What is the curriculum they follow?

Murray: Pre-COVID 19, our classes had 8 to 10 students, now it’s 3 to 5 students per session, so we can spread out.

We have done a couple of things to create the curriculum. We’ve pulled pieces together from Skill Mill (Interplay online for task-based learning), the National Center for Construction Education and Research, NATE [HVAC Courses], as well as content from the Illustrated Plumbing Manuals. I am in the classroom and can monitor what each student is learning online and can supplement that with real-world instruction on what we encounter in the field. Half a day is spent on online lessons; the other half, we’re going to the training lab to practice those skills, hands-on.

Right now, the curriculum is based on a three-month, eight-hours-a-day learning. We call it “boot camp.” Once a student graduates boot camp, he or she works in the field, side-by-side with a journeyman-level technician. Six months to a year down the road, we bring each apprentice back in for a refresher and a hands-on evaluation. There are performance tests each must pass before working independently with a customer.

Q: Do most students pick one track or another, plumbing or HVAC?

Murray: Some do both. From our perspective, it would be great if everyone did. But some lack the interest; others lack the proper skill set. Michael Olson and I are fully licensed journeyman plumbers and fully licensed HVAC technicians. We have the advantage of being able to model that opportunity for students who want to do both.

Q: What’s the advantage to CPI in developing its own young talent?

Murray: We have the confidence that the people we train know how to do things correctly. So much of what goes on in the trades is learning, one person to another. That system relies 100 percent on the person doing the training, teaching the right way to do the work. Without standardized curriculum, that is a crapshoot. The Training Lab allows us to make sure, before we send anyone into the field, they are trained to do work correctly — the way we want it done.

Q: Cynics say: Why spend the money on training, knowing that a trainee may leave and take the skills and all that investment to a competitor?

Murray: We hold ourselves to a very high standard. We want to be the best at turning out quality people. Better to train someone and run the risk of losing them, than not train them and run the risk that they will stay.