It was the most impressive gathering of young people interested in joining the trades that I have seen in quite some time. Iowa Skilled Trades (www.iowaskilledtrades.com), in conjunction with Home Builders Association of Des Moines (www.dsmhba.com) and the Skilled Trades Academy at Central Campus Des Moines Public Schools (https://centralcampus.dmschools.org/skilled-trades/), organized the very successful Iowa Build Read more

Featured Articles

It was the most impressive gathering of young people interested in joining the trades that I have seen in quite some time. Iowa Skilled Trades (www.iowaskilledtrades.com), in conjunction with Home Builders Association of Des Moines (www.dsmhba.com) and the Skilled Trades Academy at Central Campus Des Moines Public Schools (https://centralcampus.dmschools.org/skilled-trades/), organized the very successful Iowa Build My Future event.

More than 5,000 students attended the Build My Future event held at the Iowa State Fairgrounds in Des Moines, Iowa.

Held at the Iowa State Fairgrounds, the third such event held live since its inception, Iowa Build My Future far surpassed any past events with more than 5,000 middle school, high school and other students—from more than 120 schools from across the state of Iowa—bussed in to take part of this career day, industry showcase and hands-on trades expo held April 13.

Students from across the state of Iowa participated in the hands-on Build My Future event, which included testing tools, working with ropes, roof building, excavating demos, and much more.

Brandon Patterson, architect of the Build My Future event in Iowa, is all smiles as the event went off without a hitch.

“The goal is to have the students get their hands on things they’ve never done before. Maybe they don’t have shop class, maybe they’ve never understood of any careers in manufacturing. We are letting them have a hands-on experience with these different careers,” says Brandon Patterson, workforce development, HBA of Greater Des Moines, the driving force behind the event.

Those different careers include plumbing, HVAC, electrical, carpentry, masonry, welding, and more. Housed inside and out, hands-on activities included soldering, roofing, welding and jobsite excavator demos, rope climbing with harnesses, and much, much more.

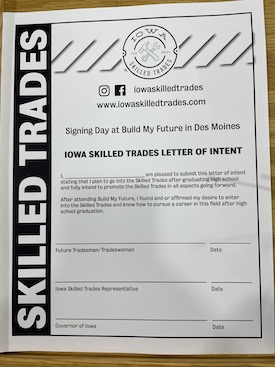

Students getting ready for the letter of intent signing.

During the show, there was a Letter of Intent signing, indicating that students intended to enter the trades after high school. “We are actually going to do a signing day for kids that are going into the skilled trades industry, most likely construction. We want to showcase these kids and show them what it’s all about,” says Patterson.

The letter also was co-signed by Iowa Governor, Kim Reynolds, who was in attendance for the Build My Future event. “I want to congratulate the students here today for taking the initiative to jump start your careers in apprenticeships that gives you an advantage; it gives you hands-on experience, a chance to earn while you learn, and it’s exciting,” said Reynolds.

The letter also was co-signed by Iowa Governor, Kim Reynolds, who was in attendance for the Build My Future event. “I want to congratulate the students here today for taking the initiative to jump start your careers in apprenticeships that gives you an advantage; it gives you hands-on experience, a chance to earn while you learn, and it’s exciting,” said Reynolds.

Reynolds continued, “I’m excited about the growth in Iowa’s registered apprenticeship programs. In 2021, we received 181 new programs in our state, the most ever in a single year and it puts Iowa as the national leader … we are going to continue to work with the kids, business, construction and the trades and we are going to transform the state of Iowa.”

Students were given plenty of swag from the event.

The letter signing was supported by RIDGID, Pfister, Iowa Skilled Trades and American Plumber Stories, and some key swag was given away at that time.

The Build My Future event left quite an impression on those attending, especially Mechanical Hub’s Eric Aune. “I wish I had something like this when I was in high school,” says Aune.

Prior to the Build My Future event, Mechanical hub was treated to a tour of the Skilled Trades Academy at the Central Campus in downtown Des Moines, Iowa. Tour guides Dan Knoup, executive officer, HBA of Greater Des Moines and Gary Scrutchfield, Lumberman’s Drywall & Roofing Supply, who are both active with the Skilled Trades Academy.

The Academy is open to 42 school districts and offers 89 various program courses from agriculture to electrical to plumbing to automotive to carpentry to marine biology. Yes, marine biology. High school students are transported there for a minimum of 90 minutes per visit to get them educationally on the right trade track.

The Hub’s Eric Aune interviews Mike Murphy, a former U.S. military serviceman, heads up the plumbing and mechanical department for the Skilled Trades Academy.

Central Campus complements and extends the programs of Central Iowa Schools, offering unique academic and career opportunities that direct, inspire, and motivate a diverse group of students.

Located at the heart of the model district for urban education, Central Campus offers hands on, real world work-based educational programs to a highly diverse community and surrounding areas. One of our greatest strengths is the friendships and networking of students from diverse backgrounds and communities. Des Moines Public Schools dedicates itself to excelling at unique and technologically advanced opportunities for all learners. Central Campus commits itself to providing equal access and prospects through rigorous academic and career training experiences for all.

Fun fact: the building was an assembly plant for Ford’s Model T.

Foley Mechanical worked with the owner of a 1920 home in the Cleveland Park section of Washington, D.C. on a heating system upgrade. The project included a 95% AFUE condensing gas boiler that replaces an existing conventional cast iron gas boiler. https://youtu.be/O_rQ1JOw6f0 Resideo hydronic products that are highlighted included the following: Hydro-Separator ECM Pumps Zone Read more

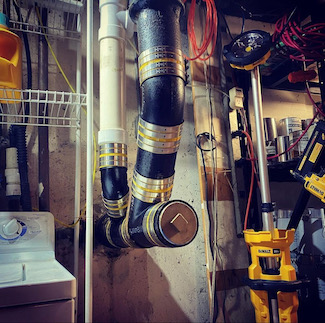

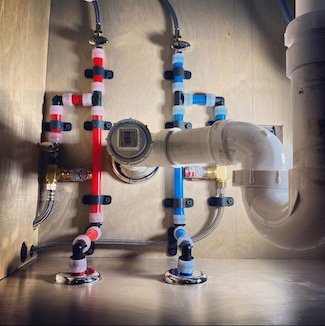

Foley Mechanical worked with the owner of a 1920 home in the Cleveland Park section of Washington, D.C. on a heating system upgrade. The project included a 95% AFUE condensing gas boiler that replaces an existing conventional cast iron gas boiler.

Resideo hydronic products that are highlighted included the following:

- Hydro-Separator

- ECM Pumps

- Zone Valves

- Relay Controls

- Expansion Tank

- Fill Valve and Backflow Preventer

Radiant floor heat was added to a new basement concrete slab. The existing cast trim radiators on the three upper floors were RE-piped and RE-valved. Foley Mechanical used this opportunity to zone by floor using Resideo zone valves. Nearly six months in and in February the owner shared that he had never been more comfortable in his home.

For more information about the Resideo products in this sponsored installation, please visit HERE.

“If pipes are involved, it’s my specialty,” says Matt Benevides, owner of Benevides Plumbing & Mechanical Inc., New Bedford, Mass. A self-proclaimed workhorse, Matt’s journey didn’t quite start off working with pipes. Benevides went to a vocational school for welding and sheet metal, got a job hanging duct work in schools for about three years Read more

“If pipes are involved, it’s my specialty,” says Matt Benevides, owner of Benevides Plumbing & Mechanical Inc., New Bedford, Mass. A self-proclaimed workhorse, Matt’s journey didn’t quite start off working with pipes. Benevides went to a vocational school for welding and sheet metal, got a job hanging duct work in schools for about three years until he eventually got laid off. “My grandmother kept telling me to be a plumber like her father; that way I’d never get laid off. I took her word and jumped,” says Benevides.

“If pipes are involved, it’s my specialty,” says Matt Benevides, owner of Benevides Plumbing & Mechanical Inc., New Bedford, Mass. A self-proclaimed workhorse, Matt’s journey didn’t quite start off working with pipes. Benevides went to a vocational school for welding and sheet metal, got a job hanging duct work in schools for about three years until he eventually got laid off. “My grandmother kept telling me to be a plumber like her father; that way I’d never get laid off. I took her word and jumped,” says Benevides.

Benevides started his apprenticeship for a large outfit just outside of Boston in 2006. “They hired me with no experience, no apprenticeship card—probably hired me because I broke out my funeral suit for the interview,” says Benevides.

When Benevides thinks back, he realizes that the opportunity doesn’t happen very often where a company takes a chance on someone and provides them with in-house schooling for three years—as long as you passed. “Once I received the ticket, my next goal was to work my way to foreman,” says Benevides.

Benevides worked his way to become the lead guy on projects until the company had the confidence in him to run small projects. They then gave him a van and he ran small commercial projects and commercial service. “Once I grew out of that spot, I knew I wanted to run larger projects so I switched companies to run larger projects like schools and a marine biology center, for example.”

Benevides worked his way to become the lead guy on projects until the company had the confidence in him to run small projects. They then gave him a van and he ran small commercial projects and commercial service. “Once I grew out of that spot, I knew I wanted to run larger projects so I switched companies to run larger projects like schools and a marine biology center, for example.”

Once Benevides figured out he could do the work, he was looking for something else and started doing residential side work at night and weekends. “After a year, I was able to take off on my own, and now I’m on year two.”

Leading the Way

Leading the Way

Benevides owes a lot of his work ethic and drive from watching his dad his entire life. “My dad owned and operated his own landscaping business, and seeing that made me want more.” As far as the trades are concerned, Benevides had a foreman named Steve Lima who started with him as a 2nd year apprentice and followed him around. “He showed me the ins and outs of plumbing and running commercial jobs. I called him my ‘plumbing father,’” says Benevides.

Benevides says that he wants to pay it forward through his Instagram page (@boston_plumbing_monstahs_). “I would hope that I’m making the trade more enjoyable so visitors to my page can see the ins and outs of plumbing rather than a plumber equals a plunger,” says Benevides. “Social media is the way to kids these days so I’d say we are on the right road.”

Moreover, the Instagram page has recently led to some local jobs and the opportunities are endless, says Benevides. “You never know who will see something you post.”

Moreover, the Instagram page has recently led to some local jobs and the opportunities are endless, says Benevides. “You never know who will see something you post.”

Balancing work with leisure time is not always that easy. Beneivdes’ spare time is dedicated to his family, if I’m not working, I’m trying to be there for my wife and four kids. “I do my best to be there when my family needs me, and I take at least one day off a week. When the weather gets warm again, I make sure to bring the kids outside as much as possible. Other than that, I plumb.”

In our continuing Industry Forecast series, we talk with John Hazen White, Jr. – Executive Chairman & Owner of Taco Comfort Solutions, on topics such as the short-term economy, supply chain issues, and lessons learned over the course of the pandemic. Here is our exclusive Q & A with John Hazen White, Jr.: Read more

In our continuing Industry Forecast series, we talk with John Hazen White, Jr. – Executive Chairman & Owner of Taco Comfort Solutions, on topics such as the short-term economy, supply chain issues, and lessons learned over the course of the pandemic. Here is our exclusive Q & A with John Hazen White, Jr.:

In our continuing Industry Forecast series, we talk with John Hazen White, Jr. – Executive Chairman & Owner of Taco Comfort Solutions, on topics such as the short-term economy, supply chain issues, and lessons learned over the course of the pandemic. Here is our exclusive Q & A with John Hazen White, Jr.:

MH: We’ve all experienced supply chain shortages, whether it’s industry related or things such as computer chips, plastics, bacon, etc., for example. Do you project a turnaround soon or within the next 6-12 months for certain materials that relate to your specific company?

JHW: Due to the China’s current COVID lockdowns and further supply chain disruptions caused by the war in Ukraine, we believe that chain issues are going to get worse over the next several months. Much of the processing of base raw materials and secondary materials has been shut down, further straining the supply chain. Exacerbating these issues, the skyrocketing costs of fuel and transportation are going to make the delivery of goods more costly.

MH: We are in the midst of some of the highest inflation rates since the early ‘80s. Do you think that higher inflation becomes a “newer normal”? Explain.

JHW: Eventually costs will temper demand and inflation will slow. Unfortunately, this will be accompanied by an economic downturn. The risk is that governments may try to artificially stimulate the economy, which could potentially prolong the inflationary upturn.

MH: In general, how do you see the economy short-term? Give a few examples of how you draw that conclusion (housing starts, commercial construction, etc.).

JHW: The short-term economy appears to be healthy. Orders remain strong and backlogs are at all-time highs. Data such as housing starts point to continued growth in 2022, with low inventory levels and a tight rental market driving that growth. In addition, manufacturing construction is on the rise to meet capacity demands.

MH: Where are you seeing signs of positivity, if any?

JHW: Short-term, the economy appears to still be growing, but at a slower pace. Although the last two years have been very challenging, these challenges can also serve as a catalyst for improvement. Companies are reinventing their structures and processes to adapt to a much faster business pace. We’re seeing step changes in productivity, efficiency, and innovation to keep up with today’s challenges and changing business environment.

MH: How do you as manufacturers work with customers who are dealing with longer lead times and/or higher prices? Is it a matter of open lines of communication?

JHW: Constant communication and strong partnerships are great ways to manage through the current supply chain and production issues. Most customers understand the challenges that all manufacturers are currently dealing with – they just want to be kept informed to minimize surprises and plan their projects accordingly.

MH: It seems that in today’s employment landscape, it’s hard to find good labor, whether it’s truck drivers, waiters at restaurants, etc. In our industry, how do we continue the fight to highlight the trades as a great career choice?

JHW: Social media is a great way to reach future tradesman of our industry. We have been running a social media campaign called #TradePower, which highlights successful contractors in the industry and the pride they take in their craftsmanship and service. Above all else, Taco has benefited by continuing to do what we always do – treat people right.

MH: In spite of COVID, people must move on. How has your company evolved—or continued to march forward—over the past two years, and talk about any new initiatives, expansions, etc.

MH: In spite of COVID, people must move on. How has your company evolved—or continued to march forward—over the past two years, and talk about any new initiatives, expansions, etc.

JHW: The sudden disruption of COVID restrictions in 2020 forced a much faster adoption of planned technology upgrades. A planned rollout of organizational digitization was condensed from 18 month to two weeks, which gave us the ability to continue functioning and growing in the new work-from-home reality. One of the biggest positives we saw during the pandemic was the rise of global collaboration. The quick adoption of virtual meetings boosted our collaboration with our entire global workforce, ensuring the best players were part of any team meeting. This has led to an increased sharing of ideas on everything from safety protocols to operational improvements. More than ever, we are thinking globally to optimize our resources and maximize our growth.

The importance of inventorying the right tools + supplies Last year, Keefer Rader, owner of Albuquerque-based Outlaw Mechanical, a shop that specializes in light commercial work, including kitchens, had one of those experiences that confirmed the value of an investment he’d made just weeks earlier. Well, he didn’t buy cryptocurrency or Spotify stock at just Read more

The importance of inventorying the right tools + supplies

Last year, Keefer Rader, owner of Albuquerque-based Outlaw Mechanical, a shop that specializes in light commercial work, including kitchens, had one of those experiences that confirmed the value of an investment he’d made just weeks earlier.

Well, he didn’t buy cryptocurrency or Spotify stock at just the right time if that’s where your imagination was going with it.

The event that triggered confirmation of a diagnostic tool’s purchase was a visit to a popular wedding venue in Colorado, a full day’s drive (or night, in this caser) from his shop.

Keefer Rader, owner of Outlaw Mechanical.

350 miles from home base

Several years before he founded Outlaw Mechanical at the age of 21, Rader worked in remote Colorado, maintaining the property and mechanical systems on a private ranch – a destination that’s won recognition as a luxurious wedding/events venue. Though his firm – now 15 years old – has won recognition as the “Number Two-rated” mechanical firm in Albuquerque, he’s maintained ties in Colorado.

“My family and I love the area, and there are still folks in Colorado who insist that I serve as their mechanical systems pro – even at a distance of 350 miles,” he said. So it wasn’t a complete surprise to hear from a man who manages a mountaintop wedding venue outside of Durango, CO – just several days before a large gathering was to lease the facility for a ceremony.

Apparently, a large kitchen broiler – “absolutely needed by the caterer,” he said – wasn’t performing well. The new manager was instructed to get Rader out to fix it.

The Watts/Dormont Flo0Pro-MD is protected by its own hard case, and is easily portable.

“I tried to help him diagnose and trouble-shoot the problem, but I quickly learned that they’d already attempted to solve the problem [to no avail],” said Rader. “So, with less than a week before the large group arrived for the wedding – and with plenty of work to do in Albuquerque – Rader swept his schedule to allow time for a Friday night drive to Durango, hoping to have the problem solved for a drive home the next day.

“The challenge with remote site work is the need to pre-think everything,” he added. “Would I have the right materials and supplies and spare parts with me, and anything else I might need to complete the job in one trip?”

By Friday afternoon, Rader visited a local supplier, buying some spare parts for the large, commercial kitchen broiler. He ran between the truck and his shop’s well-stocked shelves a dozen times before his departure and was soon on his way, driving most of the distance that evening.

Keefer Rader, owner of Outlaw Mechanical, retrieves the FloPro-MD from his truck.

The next day, Keefer drove the last 20 miles to the wedding venue. “Just after sunrise, the site was open just as the manager promised,” said Keefer. He quickly found the griddle and set to work.

“I found that the broiler worked, but not well enough. It needed more [LP] gas for more heat,” he explained. Rader was unable to use a conventional manometer as the broiler didn’t have the test ports that he typically used for diagnosing hydronic boiler problems.

He went to the truck for the FloPro-MD diagnostic tool. “It’s now one of my go-to tools for gas appliance work,” he said. “The FloPro showed that the pre-regulator gas flow and pressure were good, but on the regulator’s other [outgoing/supply] side, I began to see my problem.”

The Watts/Dormont FloPro-MD is a portable 3-in-1 gas flow meter, digital manometer, and calculator that helps service technicians and installers perform equipment start-ups, commissioning, and quickly diagnose gas flow or gas pressure issues with gas-burning appliances.

Among the supplies Rader learned long ago to keep in his truck: several gas regulators. “The FloPro made it perfectly clear that the broiler’s regulator had failed. Once connected, the new regulator provided greater gas pressure to the broiler which worked as intended, with plenty of heat for the caterer set to arrive that afternoon.”

Rader explained that, as the tool is connected to the gas line, and is out of the way, he especially likes the [FloPro-MD’s] ability to diagnose problems while the appliance is operating. “Managers at most commercial kitchens refuse to allow trouble-shooting or maintenance work during hours of operation because of the need to shut the appliance down – or, even worse – to cut gas service at a manifold to several gas appliances. Not with this tool – it’s designed to work while the appliance is in use.”

The FloPro-MD performs its diagnostic tasks, and provides useful data, while in-line (as gas courses through it). Here’s the device, in place, while flames heat the griddle following Keefer’s successful fix.

“The FloPro does the work of a variety of other tools,” added Rader. “It offers the function and intelligence of a manometer, and a gas flow meter, too. It offers precise diagnostics, with plain English on the screen. My hat’s off to the [tool’s] designer. The FloPro now has a permanent place in my truck.”