PEX Protects Pedestrians and High-End Flooring At City’s Prestigious Place Ville Marie Every winter in Montreal, an army of municipal employees works around the clock, running one of the largest snow-removal operations in the world. Up to 3,000 personnel and 1,000 snowplows are mobilized to collect 300,000 truckloads of snow from 10,000 kilometers of city Read more

Featured Articles

PEX Protects Pedestrians and High-End Flooring At City’s Prestigious Place Ville Marie

Every winter in Montreal, an army of municipal employees works around the clock, running one of the largest snow-removal operations in the world. Up to 3,000 personnel and 1,000 snowplows are mobilized to collect 300,000 truckloads of snow from 10,000 kilometers of city streets.

The volume of material is almost as impressive as the means in which it is gathered and disposed of — snow removal in Montreal is carried out with military-like precision. And in Montreal they don’t just plow the streets. They also plow the sidewalks. When Montrealers talk about snow removal, they mean getting rid of it, not just pushing it to the side of the road. Here’s how it works:

When significant snow is forecast, signs go up announcing on-street parking bans. The day of the event, tow trucks cruise the streets blaring a warning to vehicle owners still parked in snow-clearing zones. If the cars aren’t removed within minutes, they are towed. Snow is then plowed to the center of the street, where a giant snow blower sprays it into a truck, which transports the snow to one of the city’s 29 snow dumps. A convoy of dump trucks repeats the procedure.

This well-run system is required in a city known not only for its Stanley Cup-winning hockey franchise, the Montreal Canadiens (known to locals as “The Habs”), but its brutal winters. Sometimes, however, it just isn’t possible to use a mechanized army of plows and shovels.

Severe winters are etched into the memories of Montrealers, when large accumulations of snow and ice combined with high winds have destroyed power lines, leaving some areas without electricity for days and residents dying.

A particularly nasty cold spell occurred in 2015, when for 12 days straight, temperatures plunged below -20 Celsius, making it the coldest February in Montreal in more than 100 years.

Fortunately, the modernization of the city’s downtown has brought with it the construction of areas where Montreal inhabitants can go to enjoy a pedestrian experience free of snow and ice. One of those is Place Ville Marie (PVM), a large skyscraper and shopping complex. Its four towers and spacious Esplanade is a nexus for Montreal’s underground city, with indoor access to over 1,600 businesses, several subway stations, a suburban transportation terminal and tunnels extending throughout the downtown.

Designed by Henry Cobb, of award-winning New York architectural firm Pei Cobb Freed & Partners, Place Ville Marie was built in 1962 to serve as the official headquarters of the Royal Bank of Canada, which it remains today.

According to design historian Mark Pimlott, via Wikipedia, “The most radical aspect of the Place Ville Marie project was that nearly one-half of its 280,000 square meters area were beneath street level, deriving the obvious benefit of being protected from Montreal’s extreme winter and summer climate.”

At time of construction, the main tower was the tallest in the British Commonwealth and the third highest skyscraper on Earth outside the United States. As for its moniker, former Montreal mayor Jean Drapeau reportedly chose Place Ville Marie for the name of the Catholic colony founded by what is now Montreal in 1642.

Fast forward to 2017 when Place Ville Marie received a make-over thanks to real estate firm Ivanhoe Cambridge, whose $1 billion Projet Nouveau-Centre featured plans to refurbish its flagship downtown properties, including PVM, Fairmont The Queen Elizabeth Hotel, Maison Manuvie, and Montreal Eaton Centre.

A $200 million investment revitalized the Esplanade (the central public space between the office buildings) and renewed the commercial offerings at Place Ville Marie. To execute the historic project, Ivanhoe Cambridge called upon Montreal firms Sid Lee Architecture and Menkès Shooner Dagenais Létourneux Architectes.

“Our primary goal is for this civic space to be a catalyst for downtown social activity,” Jean Pelland, architect and senior partner, Sid Lee Architecture, said at the time. “Given the importance of this iconic space, we sought additional exposure to urban activity, making it more accessible and usable. Our major architectural interventions are in line with this desire for great openness.”

An important part of the project’s ethos to breathe new life into the area, and position it as a social, cultural, and commercial hub, was to install a snow and ice removal system.

The restricted access for snow removal equipment, coupled with the upscale finish of the surface material, made mechanical and chemical snow removal at Place Ville Marie unfeasible. The owners turned to HeatLink Group, Inc. (Calgary, Alberta), a manufacturer and supplier of radiant hydronic heating/cooling and snow melt systems, to spec the job and supply the PEX-a tubing, loops and manifolds.

The Calgary-based company’s PEX-a snow and ice melt system eliminates the need for those other methods, helps to preserve the manufactured stone finish without abrasion caused by shovels or chemical attack from salt, and ensures pedestrians can safely and comfortably enjoy the space and use the stairs at any time of day or night in the wintertime.

At 120,000 square feet that would need nearly 50 miles of PEX-a tubing, the Esplanade at Place Ville Marie was the largest snow and ice melt project HeatLink had ever contemplated, certainly on par with the radiant heating/cooling system the company designed for the Vancouver Convention Centre. The six-floor facility is a global hub for conferences and trade shows; in 2010 it was used to host the medal ceremonies for the Winter Olympics. Place Ville Marie is comprised of pedestrian areas, stairs, and multiple levels of commercial space, incorporating a beautiful glass-roofed pavilion in the center.

The company worked closely with its distributor, Agence Jacques Desjardins Inc., and engineer Bouthillette Parizeau, to manufacture and supply 260,000 linear feet (79,300 m) of ¾-inch PEX-a tubing that was installed in 679 circuits or loops. A challenging aspect of this outdoor project was where to place the 77 supply and return manifolds, which distribute the heated fluid with 50 percent glycol solution to the numerous zones set up for snow melting. The 13-phase endeavor is the largest snow melt project in Montreal and ranks as one of the most extensive on the continent, according to the Plastics Pipe Institute, Inc., the major North American trade association representing the plastic pipe industry.

“The first hydronic snow and ice melting systems were installed in the 1930s using steel piping that was welded together and encased within concrete,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division. “Those systems performed well and proved the concept, although the piping would start to fail after several years due to corrosion.”

Today, the majority of SIM systems utilize PEX – crosslinked polyethylene or PERT – Polyethylene of Raised Temperature resistance tubing. The PEX tubing used in this project is a flexible piping material with high temperature and pressure capabilities and incredible toughness.

“Hydronic SIM systems using fluid-filled pipes are known worldwide for their high degree of safety and convenience. Additional benefits include reduced liability, lower maintenance costs and long-term reliability, all important factors for building owners. Hydronic systems typically use far less energy to simply melt snow and let it flow down the storm drain than would be required to plow the snow and truck it away. Plus, because melting snow and ice prevents the need for salting and sanding, there is very low environmental impact, which fits in very nicely to Montreal’s sustainable development plan.”

The large surface area required thoughtful placement of manifolds to ensure efficient use of energy and tubing. The project used cleverly designed sliding panels to hide, protect and access manifolds that needed to be located close to pedestrian areas.

Manifolds ranged from four loops to 20 loops. In a couple of areas, two manifolds had to be joined together. “Snow melting systems require relatively high flow rates of heated antifreeze, as compared with indoor radiant heating systems, due to the energy requirements for melting snow during extreme weather events,” said Byron Stadnyk, HeatLink Group’s senior tech & design support. “Therefore, the tubing design has to allow for precise delivery of the heated fluid where it is needed, without incurring excessive pressure losses. There are engineering limits on how long the loops can be.”

All parties involved in the installation needed to make sure that the tubing loops followed the design specifications for on-center spacing, tubing patterns and circuit lengths. The nominal ¾ inch tubes at Place Ville Marie are spaced six inches (15 cm) apart. The project was designed to deliver a heat output of up to 150 Btu/h-sq.ft.

“You don’t want little piles of snow in between your loops, so adequate tube spacing is critical. The loop length has to be under a certain amount to make sure that selected circulator pumps can be used to efficiently deliver flow to all the areas as needed,” noted Mike Casavant, HeatLink’s technical manager. “There are a lot of technical constraints that people don’t even realize, that make a big, complicated project like this even more complicated.”

The tubing was positioned in a bed of leveling sand. It’s vital that the entire substrate be heated, along with the surface material, which at Place Ville Marie, consists of two-inch-thick manufactured stone.

“The challenge is to heat up the sand enough to be able to heat up the stone, to have high enough temperature at the surface to melt snow,” said Stadnyk.

The water-glycol supply is heated to 134 Fahrenheit (57 degrees Celsius) and pumped and distributed through the loops and manifolds to reach all of the heated areas. When snow begins to accumulate, sensors embedded in the surface stone activate the snow melting system. The heat sources are non-dedicated boilers that also heat the buildings.

With 260,000 linear feet of tubing installed underneath a finished-stone slab, it is important that the material is able to withstand the countless cycles of heating and cooling; nobody wants to be conducting an excavation to repair cracked tubing in the heart of downtown Montreal in the dead of winter. “The proven performance of HeatLink’s PEX-a tubing will ensure that such issues will not occur,” MacNevin stated.

A tekmar® Snow Melt Control 680 unit communicates with the building’s automation systems using BACnet® – the data communications protocol for building automation and control to provide alert notification, remote monitoring and adjustments. It uses sixteen tekmar Snow/Ice 090 Sensors to automatically detect snow or ice on the snow melting slab and meet demand on a priority basis.

A tekmar® Snow Melt Control 680 unit communicates with the building’s automation systems using BACnet® – the data communications protocol for building automation and control to provide alert notification, remote monitoring and adjustments. It uses sixteen tekmar Snow/Ice 090 Sensors to automatically detect snow or ice on the snow melting slab and meet demand on a priority basis.

According to PPI, PEX is a polyethylene material which has undergone a change in molecular structure using a chemical or a physical process whereby the polymer chains are chemically linked. Crosslinking of polyethylene into PEX for tubing results in improved properties such as elevated temperature strength and performance, chemical resistance and resistance to slow crack growth.

Casavant compares PEX tubing to the tires on a car. “A long time ago tires were just natural rubber and they would fall apart in short time. Charles Goodyear discovered that if he crosslinked the rubber through “vulcanization”, the modified rubber would resist the abuse of the roads and last much longer,” he said. “Standard thermoplastic materials can be heated and reformed into various shapes. Crosslinked polyethylene doesn’t do that. Once you’ve extruded the material into tubing, if you try to do anything to it, short of grinding it, it will always stay in the shape of that piece of tubing. You could heat it up and tie it into a knot, and you could even undo it, it’ll still be a piece of tubing. As long as you don’t cut the tubing, it will always hold its shape.”

The industry states that PEX tubing has an expected design life in excess of 50 years for projects such as this one.

“The success of the snow removal system at Place Ville Marie should encourage other engineers and architects to consider hydronic SIM systems for large public spaces, especially in downtown urban areas,” MacNevin stated.

“I think the more people realize that a job of that scale can be done, they’re not going to be afraid of it,” Stadnyk said.

“The high visibility and usage of this area will highlight the benefits of snow melt systems, not only to knowledgeable professionals in the heating industry, but also to the general public who will appreciate how accessible this space is in the winter. In the plastic pipe industry, our products and their benefits are largely invisible to the casual user, but in this case, people will notice immediately when they step from the snowy city sidewalk onto the PVM property,” said Casavant.

“It’s one thing to see a driveway being snow-melted, but it’s a very different thing to see this huge promenade where people are literally walking onto it from the city sidewalk, kicking the snow off of their boots and they don’t have to worry about slipping and sliding on the steps because the steps are all melted. I think they’re going to see that and say, ‘I love taking this route because of these reasons.’”

More information about SIM systems plus technical information can be found at the PPI Building & Construction Division’s website: https://plasticpipe.org/BuildingConstruction

By Aaron Stotko When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high. That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion Read more

By Aaron Stotko

When a century-old Dallas railroad company headquarters required major renovations to transform into a Homewood Suites by Hilton, initial cost estimates for the hydronic heating system came in too high.

That’s when City Wide Mechanical of Dallas looked to alternative piping systems for a solution. They found PEX-a pipe with F1960 expansion connections to be the ideal system, due to its durability and ease of installation in addition to the job-site productivity, safety and, best of all, profitability potential it provided.

And City Wide Mechanical isn’t alone in their findings. Many mechanical contractors are discovering the benefits of PEX-a pipe and F1960 connections as the preferred alternative to copper, iron, and steel, which have dominated the mechanical piping industry for decades.

Benefits of PEX-a

PEX is an acronym for crosslinked polyethylene. It has been used in North America since the mid-1980s, starting with radiant floor heating systems, then moving into plumbing and, eventually, to hydronic hot-water heating and chilled-water applications.

PEX can be manufactured via three different processes, which create products with varying crosslinking percentages that allow for different characteristics. PEX-a is the most durable, flexible, and resilient with crosslinking around 85%. PEX-b is a stiffer piping product with crosslinking around 65% to 70%, and PEX-c features crosslinking around 70% to 75%.

ASHRAE Headquarters Grand Opening Fall 2021, photos by Devin Abellon

One major benefit of the higher crosslinking in PEX-a is its extreme flexibility along with its thermal and shape memory. The flexibility of PEX-a eliminates most connections in smaller-diameter piping, saving time and money with up to half the connections required in rigid metal piping systems. To make a change in direction, the installer simply bends the pipe instead of having to stop and make a fitting. There are also bend supports available that help hold a bend securely in place.

The thermal memory of PEX-a provides kink repairability with a simple shot of heat from a heat gun. This eliminates the need to add in a coupling if a kink ever occurs in the pipe. (It is important to note that kink repairability is not possible with PEX-b or PEX-c pipe.)

The shape memory of PEX-a allows the pipe to expand and contract back down to its original shape. This makes it extremely resilient in freezing conditions and also provides for the fastest, easiest, most reliable PEX-a fitting system — F1960 expansions.

Expansion fittings require one simple tool to expand the pipe and an expansion ring before inserting a fitting. As the pipe and expansion ring naturally shrink back to their original shape, it creates a strong, durable connection that holds tight and can never be dry-fit. (Note: It is not recommended to expand PEX-b or PEX-c pipe due to microcracking that can occur.)

The innovative expansion fitting method eliminates torches, glues, and solder from a job site for greater worker safety. Plus, the system is extremely easy for installers to learn, helping get new crews up to speed quickly.

Speaking of job-site safety, PEX is also much lighter in weight compared with metal systems. For example, a 300-foot coil of 1/2-inch PEX weighs about 18 pounds, whereas the same amount of copper pipe weighs around 85 pounds. The lighter weight of PEX makes it safer and easier for installers to move around a job site and also eliminates the need for heavy-lifting equipment.

PEX-a also has a long-term advantage over copper when it comes to performance longevity. It is a static system, meaning its internal surfaces — which are three times smoother than copper — will not pit, scale, or corrode. That means its performance will remain the same from day one through decades of use.

Finally, because it is not a traded commodity, PEX-a holds a relatively stable material cost. This makes bidding a project much more consistent and reliable.

Application Details and Installation Tips

PEX-a is regulated by the ASTM F876 standard, which denotes temperature and pressure ratings of 200°F at 80 psi (pounds per square inch), 180°F at 100 psi, and 73.4°F at 160 psi. These values are well within the range of operation for most hydronic systems, including chilled beams, fan coil units, baseboards, radiators, hydronic VAV (variable-air volume) reheat coils, and radiant manifolds.

Because PEX is oxygen-permeable, it is important to use a pipe with an oxygen barrier that limits oxygen diffusion to levels below DIN 4726. This will protect the metallic components in the mechanical piping system, such as valves, strainers, and pump volutes, from corrosion.

The pipe is manufactured in sizes from 5/16 inch up to 4 inches and features a copper tube size (CTS) outside diameter. This means all the off-the-shelf components used in a copper hydronic piping system — hangers, supports, and insulation — can be the same.

For horizontal piping, the industry offers PEX-a Pipe Support — a galvanized-steel channel that is 9 feet in length and available in PEX pipe sizes from ½ inch to 3½ inches. This solution enables hanger spacing similar to copper pipe and helps control the natural expansion and contraction of the pipe as it heats and cools.

Because PEX-a expands at 1.1 inches per 100 feet per 10°F Delta T (which is 10 times that of copper), installing anchors every 65 feet and using PEX-a Pipe Supports allows PEX-a to function much like a copper system. In fact, different installation methods have a different effect on the overall net expansion rate.

With a strut-and-clamp system, using PEX-a Pipe Supports and anchoring with fixed points reduces the expansion rate of PEX-a to 0.08 inches per 100 feet per 10°F Delta T (a rate less than copper). And a loop-and-clevis system can reduce the rate to 0.12 inches per 100 feet per 10°F Delta T.

If you’d like to learn more about PEX-a piping systems, visit the Plastics Pipe Institute at plasticpipe.org or the Plastic Pipe and Fittings Association at ppfahome.org.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Aaron Stotko is the director of Segment Marketing at Uponor. He can be reached at aaron.stotko@uponor.com.

Name: Matthew Fleming Title: Owner Company: All-Star Plumbing & Heating Location: Manasquan, New Jersey Specialty: New Construction Large Custom Homes Although a self-described “rough around the edges” kind of guy, Matthew Fleming (@allstarplumbinginc), owner of All-Star Plumbing & Heating, Manasquan, N.J., admits he’s a girl dad, and he wouldn’t have it any other way. “I Read more

Name: Matthew Fleming

Name: Matthew Fleming

Title: Owner

Company: All-Star Plumbing & Heating

Location: Manasquan, New Jersey

Specialty: New Construction Large Custom Homes

Although a self-described “rough around the edges” kind of guy, Matthew Fleming (@allstarplumbinginc), owner of All-Star Plumbing & Heating, Manasquan, N.J., admits he’s a girl dad, and he wouldn’t have it any other way. “I have no problems laying on the floor and playing dolls with my daughters,” says Fleming. He says that at some point you have to be able to shut OFF work and turn ON home.

And while spare time doesn’t happen as often as Fleming would like, when it does, he loves hanging at the beach with his wife and kids. He also tries to make time to work out at the gym every morning to clear his head and start the day right. “Work will always be there tomorrow so you need to make sure that you’re not missing those important life/leisure moments that you can’t get back.”

It’s a Generational Thing

With Fleming’s father owning a family plumbing business, it was a simple decision to get into the plumbing industry. Fleming went to college for business administration and construction management to at least give himself a solid base of business knowledge if he was to ever take over the company. A solid decision as it turns out. “I started plumbing when I was about 16 years old but would always help out my dad as a kid. I worked part time through school and college. Once I graduated college, I jumped in full time and I’ve never looked back,” says Fleming.

The Ultimate Influence

Fleming has recently officially taken over the company that his father started 30+ years ago. And it was his father that molded Fleming into the craftsman that he is today. “He instilled in me the values of hard work and determination,” says Fleming. “He was always pushing the envelope and would take on jobs that other plumbers and companies would shy away from. My father always embraced challenges, and after years of doing that, it became clear the you can attack difficult situations with the confidence and mindset that you have what it takes to handle it.”

Like most modest tradespeople, Fleming doesn’t consider himself a “role model” but he does feel like he has some valuable bits of advice he could pass on to the younger generation looking to get into this trade or take into whatever field they choose. “A lot of plumbing is having the ability to problem solve, and that applies to any field. I encourage people to never be content with their current knowledge and skill set, you can always find ways to improve,” says Fleming.

Like most modest tradespeople, Fleming doesn’t consider himself a “role model” but he does feel like he has some valuable bits of advice he could pass on to the younger generation looking to get into this trade or take into whatever field they choose. “A lot of plumbing is having the ability to problem solve, and that applies to any field. I encourage people to never be content with their current knowledge and skill set, you can always find ways to improve,” says Fleming.

These days a lot of teaching and connecting with others happens through social influencing. “Social media has absolutely made a big impact on my business for multiple reasons. I’ve learned so much from so many of the incredible plumbers across the country and have made some good friends, too. I’ve gotten jobs from the work people have seen on my Instagram, but above that, seeing the amazing work that others put out makes me improve my own work. I always remind the guys that I might take a picture of their work and post it to Instagram for public ridicule by the “super plumbers,” so make sure it’s right, haha,” says Fleming. “Social media can be very valuable if you use it right, and the plumbing community is second to none on there.”

State of the Industry

“I feel like most people believe that being in the trades means that you’re a second-rate citizen and couldn’t get a “real” job,” says Flaming. When in reality, continues Fleming, it’s a respectable occupation that requires highly educated, hard-working people. And with that comes training. “There should be more educational and training options available so that people entering the trades can be trained properly, which will help raise industry standards. Increasing trade school funding to ensure that the programs available are legit programs would absolutely attract more people. They need to be proactive in recruiting instead of just waiting for kids to show up,” says Fleming.

A Hard Day’s Work

One of the most rewarding things about his work is the problem-solving aspect. “I really enjoy when the customer tells me that they had four other companies there prior and nobody could figure out the problem but we did,” says Fleming. I’d say that’s a win.

But nothing compares to when you are down and come home to see those smiling faces. “I was having a pretty rough week, put through the ringer. I came home that day feeling pretty defeated only to be greeted by my two daughters—ages 6 and 8—barreling towards me to give me a huge hug as my wife kissed me on the cheek. Instantly, I was reminded of what is really important, and even though I was having a rough patch, I was still doing a good job. It was just what I needed and I thought to myself, ‘I’m extremely lucky to have this life that plumbing has provided me.’”

But nothing compares to when you are down and come home to see those smiling faces. “I was having a pretty rough week, put through the ringer. I came home that day feeling pretty defeated only to be greeted by my two daughters—ages 6 and 8—barreling towards me to give me a huge hug as my wife kissed me on the cheek. Instantly, I was reminded of what is really important, and even though I was having a rough patch, I was still doing a good job. It was just what I needed and I thought to myself, ‘I’m extremely lucky to have this life that plumbing has provided me.’”

Michigan’s High Mountain Cannabis Co. mold and fungus prevention efforts lead to rich harvests Mold and fungus is one of the most pressing issues facing the North American cannabis growing industry. Fungus and molds, such as Botrytis, are leading causes of infections that can result in entire crop destruction and sometimes even force cannabis grow-op Read more

Michigan’s High Mountain Cannabis Co. mold and fungus prevention efforts lead to rich harvests

Mold and fungus is one of the most pressing issues facing the North American cannabis growing industry.

Fungus and molds, such as Botrytis, are leading causes of infections that can result in entire crop destruction and sometimes even force cannabis grow-op closure for weeks of remediation.

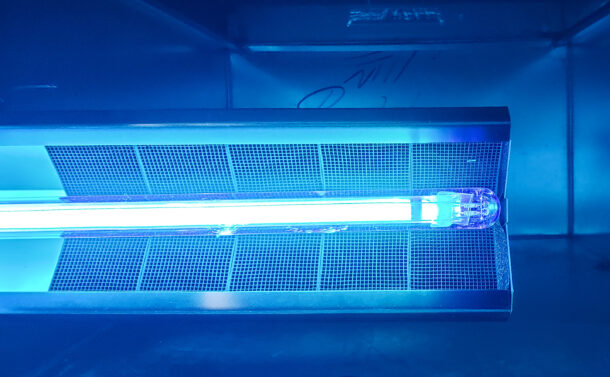

However, cannabis growers are fighting back by combating mold, fungus and other microorganisms with ultraviolet germicidal irradiation (UVGI). Cannabis grow-ops are specifically using the UV-C wavelength, which is lethal for mold, bacteria, viruses and other biological contaminants.

UV isn’t new as it has been used for more than a century to sanitize water. More recently, the HVAC industry has developed UV lamp kits for HVAC systems to prevent mold and biofilm growth inside air handler units and to neutralize airborne microorganisms as they circulate through the ventilation system.

Consequently, cannabis growers have increasingly installed UV-C germicidal lamp systems in their facilities’ air handlers. One example is High Mountain LLC, Vassar, MI, an 8,500-square-foot facility that relies on UV-C lamps in its HVAC air handlers to prevent mold and fungus contamination.

The UV-C systems, combined with tight HVAC humidity/temperature control, help grow rooms operate at sanitary levels similar to cleanrooms. High Mountain’s impressive harvests are typically three-lbs/1,000 watt light (or a minimum 100-lbs/50-light room), which is considered the high end of the productivity scale in Michigan.

Based on previous mold suppression efforts, COO/co-founder Brandon Schmitzer, plans UV-C lights for an upcoming 10,000-square-foot expansion in the wake of the facility’s addition of recreational use certification to its original 2020 medical marijuana certificate from Michigan’s Marijuana Regulatory Agency (MRA).

“Mold is a constant battle in the medical marijuana growing industry, because it’s critical to keep (microbial) colony-forming units under the strict government standards we must meet during test processes,” said Schmitzer. “UV-C is an important part of the puzzle in keeping a facility sanitary.”

Consequently, High Mountain hasn’t encountered the mold challenges other Michigan grow-ops have faced, such as remediation, harvest delaying re-testing/inspection and, in some extreme cases, crop destruction.

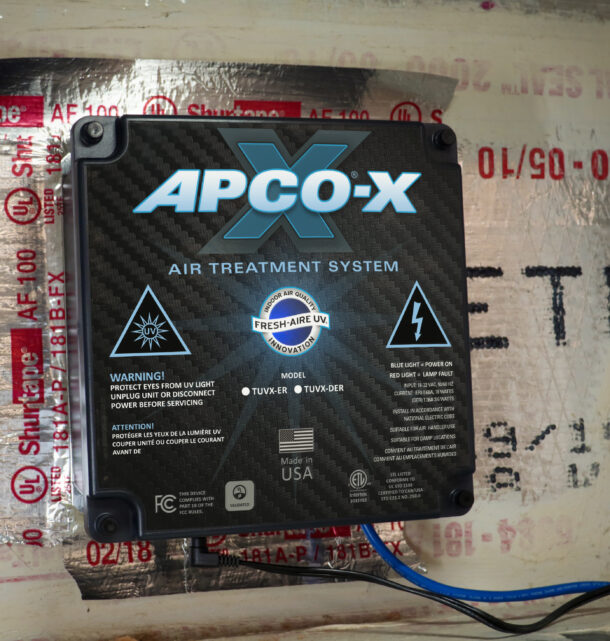

Schmitzer and his HVAC contractor, Martin Proctor, president, Proctor Plumbing LLC, Vassar, chose APCO-X, a combination of UV-C disinfection technology and activated EverCarbon™ media catalyst air treatment for HVAC systems. Manufactured by Fresh-Aire UV, Jupiter, Fla., the APCO-X units were strategically placed in air handler return ductwork between the air filter and coil to prevent mold and biofilm growth on both. The UV-C light also neutralizes airborne mold and microorganisms in the airstream. While UV-C addresses biological contaminants, the APCO-X V-Twin EverCarbon Matrix is infused with lifetime warrantied activated carbon media to adsorb volatile organic compounds (VOC). VOCs, such as material off-gassing, solvents and glues, cleaning chemicals, and general nuisance odors are removed from the airstream before grow room HVAC distribution. The EverCarbon Matrix includes an antimicrobial-coating. The APCO-X process does not introduce any additives or oxidizers into the air that may pose issues to occupants or plants.

The facility operates 22 HVAC split systems ranging from 2 tons to 5-ton, 2,000-CFM units manufactured by Goodman Air Conditioning and Heating, Waller, Texas. The three flower rooms operate six 5-ton units each with air distributed through fabric ductwork manufactured by FabricAir, Suwanee, GA. The, Combi 70 fabric duct employs an anti-microbial agent that also helps prevent surface biological growth.

The ductwork distributes air evenly through Oriflow orifice arrays that span linearly along the entire length at 5 and 7 o’clock positions. Approximately 15-percent of the air circulates through the fabric surface. This promotes uniform airflow and prevents condensation formation, which helps in facility moisture control.

Other equipment critical to High Mountain’s mechanical design includes 210-pint/day dehumidifiers and 34.6-gallon/day steam humidifiers manufactured by Anden, Madison, WI, to maintain relative humidity levels.

Preventing biological contaminants with UV-C also has an additional benefit of maintaining optimum HVAC system efficiency and cleaner air. A biofilm coating as thin as 0.002-inches can potentially reduce HVAC coil energy efficiency by up to 37%.

“We’ve been manufacturing coil and duct mount UV disinfection systems for more than 20 years for all types of building applications,” said Aaron Engel, vice-president of business development, Fresh-Aire UV. “For example, healthcare facilities employ UVC disinfection to address hospital associated infections (HAIs). Grow facilities are no different, except they’re mitigating cross-infection of plants within the facility as well as disinfecting the HVAC equipment which can introduce mold and fungus into the facility. Germs are germs. What’s important is applying the right strategy and product for the application.”

High Mountain’s five-year plan includes a goal of 10 more buildings, dependent on power availability. Regardless of the number of buildings, all HVAC systems will definitely be using UV-C to prevent mold and mildew growth on and around the cannabis plants, according to Schmitzer.

You think you have what it takes to own your own plumbing business? Every first-year apprentice dreams about it. But owning your own business someday takes hard work, perseverance and a willingness to learn. Recently, we talked with four prominent business owners about what they thought it took to go off on their own, and Read more

You think you have what it takes to own your own plumbing business? Every first-year apprentice dreams about it. But owning your own business someday takes hard work, perseverance and a willingness to learn. Recently, we talked with four prominent business owners about what they thought it took to go off on their own, and what they have learned from their experiences of ownership. Here is the advice that they shared:

Linda Hudek

Linda Hudek

Owner, LH Plumbing Services LLC

Fairfield, Ohio

The most important things were knowing my worth as a professional and licensed plumber. So many people start a business thinking their previous boss was overcharging or “lining their pockets off my back,” in their words. Don’t undercharge. Knowing and understanding expenses is so important. Your wage is not the same as the business profit.

It’s also important to not fall for the temptation of going into business too quickly when you are not knowledgeable enough in the technicalities of you field. Being uneducated or undereducated and inexperienced in plumbing can cause major property damage and even death to yourself and your customers. I went into business still lacking some knowledge that I had to learn the hard way.

Bob Baker

Bob Baker

Owner, Baker Plumbing Inc.

Master Plumber/Gasfitter

Calgary, Alberta, Canada

Cash flow is KING! You can be the best tradesperson on earth with skill and knowledge oozing from your pores! None of that matters if you ain’t getting paid. So many people start their business by market research—what’s the average hourly rate. They phone around and get some pricing and figure the average is $115 an hour so I’m going charge $105 and steal my piece of the pie through price.

Initially, it seems like a decent plan but the guy starting his business three months after you has the same plan and before you know it you’re losing those cheap clients to the cheaper guy. My suggestion is add up all your monthly expenses—rent, fuel, truck, your personal wage, etc. and determine what you need to make to meet your needs. Distill that down to an hourly rate and stick to it. If you’re good, the clients will come.

Also, the best tools don’t make you the best. It’s a hard one with all the cool tools out there these days and their splashed all over social media. Set yourself a tool budget and stick to it. The formula pertains to skills, knowledge, experience, and then tools. Expensive tools don’t make you money, your skills and knowledge do. Tools make your job easier but as I’ve told my boys, learn the hard way first so you can appreciate the easier way.

Maybe this one is too old school but I think it tracks. Your personal appearance matters! You need a uniform—you ought to wear clothes that are cleaned, pressed and smell good. You need keep your appearance neat, clean and tidy. You, your person, needs to look presentable, smell good, teeth brushed, hair combed and be well put together.

It seems obvious but I’ve seen so many people starting out looking like they slept in the back of their trucks on some random Thursday. Even in today’s wide scope of acceptance, the disheveled look is always a bad one. Personally, I carry a brand new black shirt—still in the packaging—a variety of hats and a can of deodorant in the truck for those days where the first job of day goes horrible wrong. Your first impression is of vital importance and yet so is the 10th. People notice that stuff even if it’s sub-consciously.

Andy Mickelson

Andy Mickelson

Owner, Mickelson Plumbing & Heating, LLC

Missoula, Montana

I wish I would have known how to anticipate the time required to run the behind-the-scenes portion of our business, not sure it would change anything, but nonetheless it would have been nice to know what to expect.

I have learned that every employee has their own baggage and quirks that show up occasionally and require a special set of kid gloves to handle.

I also have learned that I need to be open minded when it comes to trusting my employees to do their best and allow them to make choices that sometimes might not completely align with what I would have done.

Mike Lomonaco

Mike Lomonaco

Owner, Lomonaco Coast Plumbing,

San Clemente, Calif.

Make sure you know business; it takes more than being a good technician and wanting to go out on your own to be successful.

Know your competition, and what separates you from your competition.

Know what your definition of success is, and where to draw the line. It’s about how much money you save, not how much money you spend. Be careful what you wish for, you just might get it. To start your own business is a major commitment. It’s a lifestyle change that doesn’t stop. It is a huge toll on all aspects of life that you will have to juggle.